Miniature self-propelled ridger

A technology of self-propelled and ridging machines, which is applied in the fields of tillage machines, agricultural machines and tools, etc. It can solve problems such as insufficient adhesion between the road wheels and the ground, broken seeds, and unsatisfactory performance, and achieve the level of promoting agricultural mechanization. The development of rotary tillage, the reduction of working width and the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

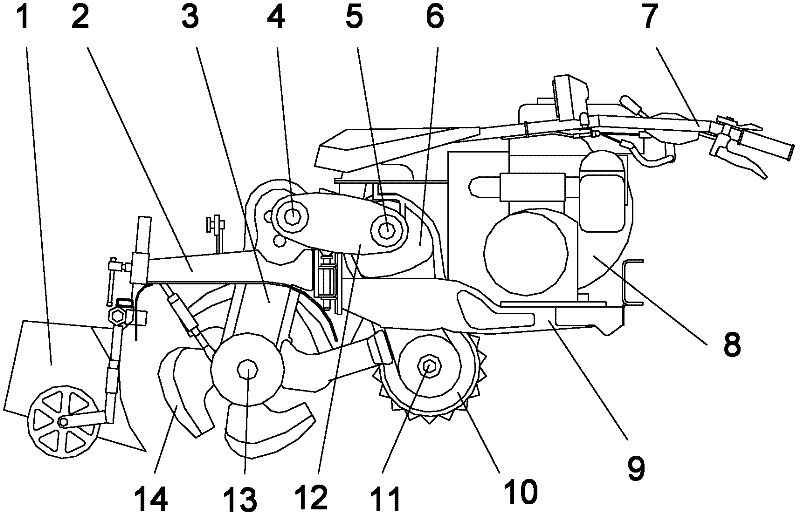

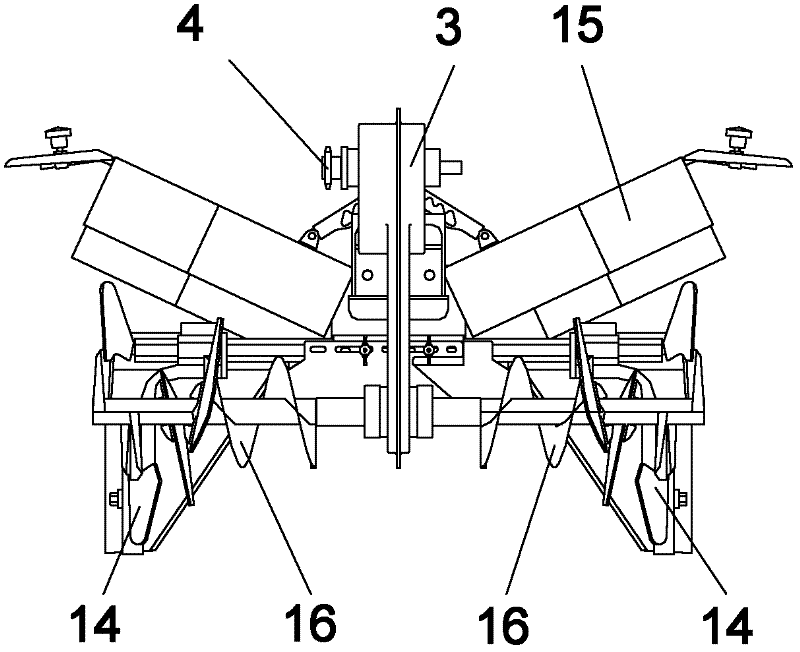

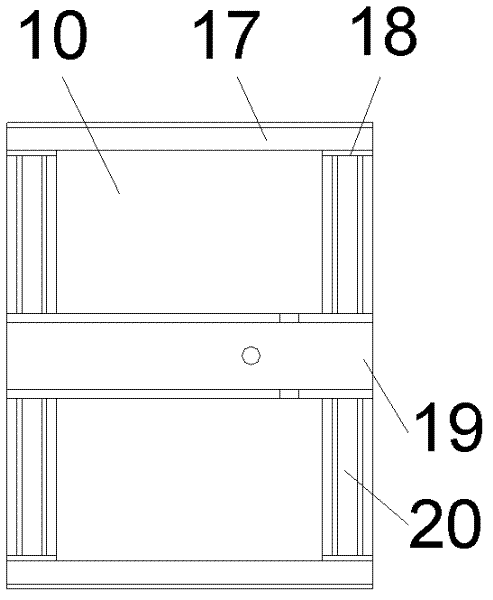

[0020] Such as figure 1 , figure 2 As shown, the miniature self-propelled ridging machine of the present embodiment is made up of power chassis, ridging part and ridge pressing part 1, and power chassis is mainly by the frame 9 that road wheel 10 is housed, the frame 9 that is supported on frame 9. The walking gearbox 6 driven by the engine 8 and the control armrest frame 7 are composed. Ridging parts are mainly composed of bracket 2, rotary tillage gearbox 3 installed in the middle of the bracket, sprocket box 12, rotary tiller roller 14, screw auger 16 and soil retaining cover assembly 15, etc., rotary tiller gearbox 3 The power input shaft 4 is connected with the power output shaft 5 of the travel gearbox 6 through the sprocket box 12, and the front and rear ends of the support 2 are fixedly connected with the frame 9 and the ridge pressing part 1 respectively.

[0021] Such as figure 2 As shown, the rotary tiller roller 14 and the auger 16 as a part of the ridging com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com