Corrugated-plate type SCR (selective catalytic reduction) denitration catalyst

A technology of denitrification catalyst and corrugated plate type, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of corrugated plate denitrification catalysts such as easy corrosion and heavy weight, and achieve light weight and easy installation And replacement, not easy to corrode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

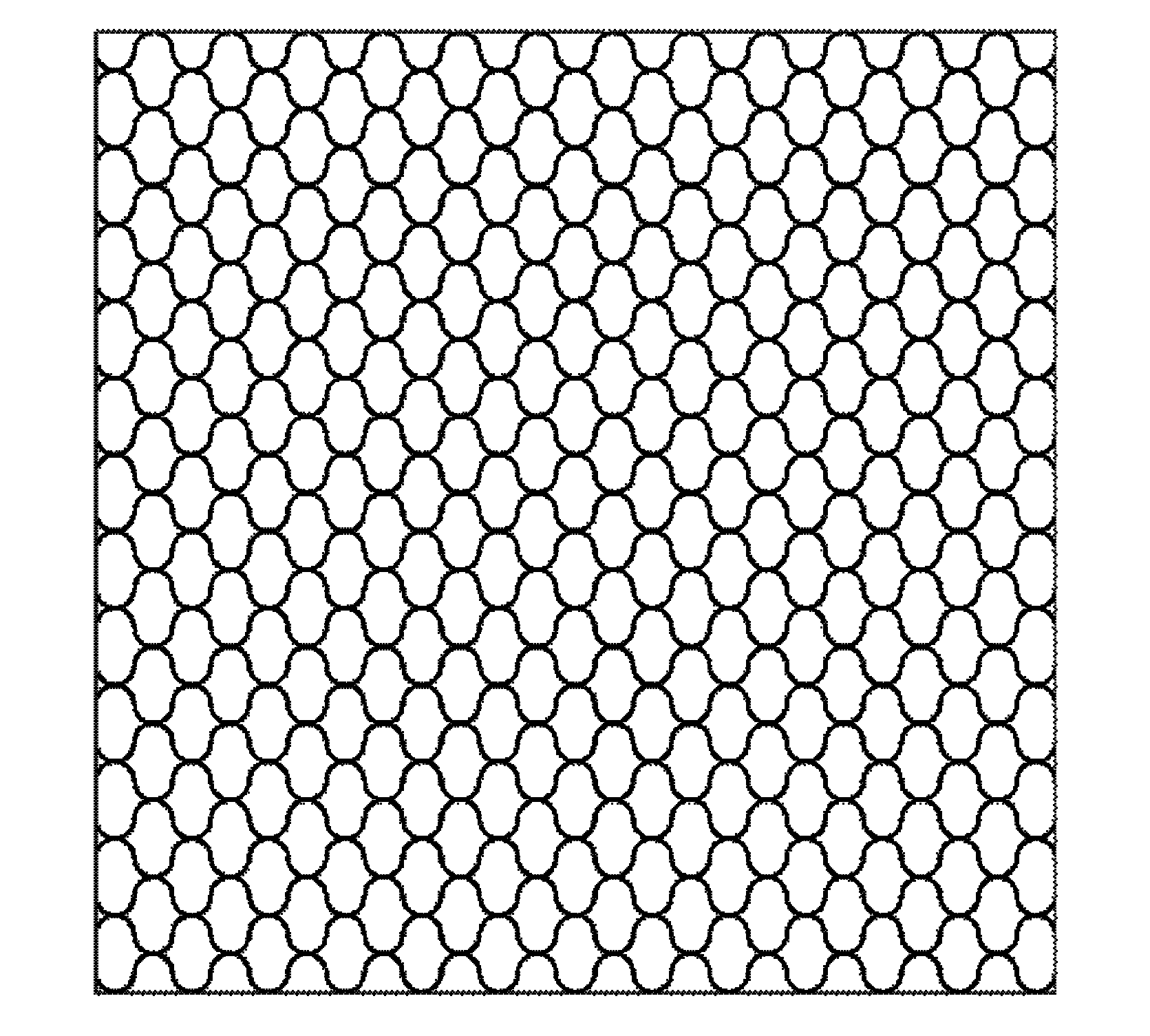

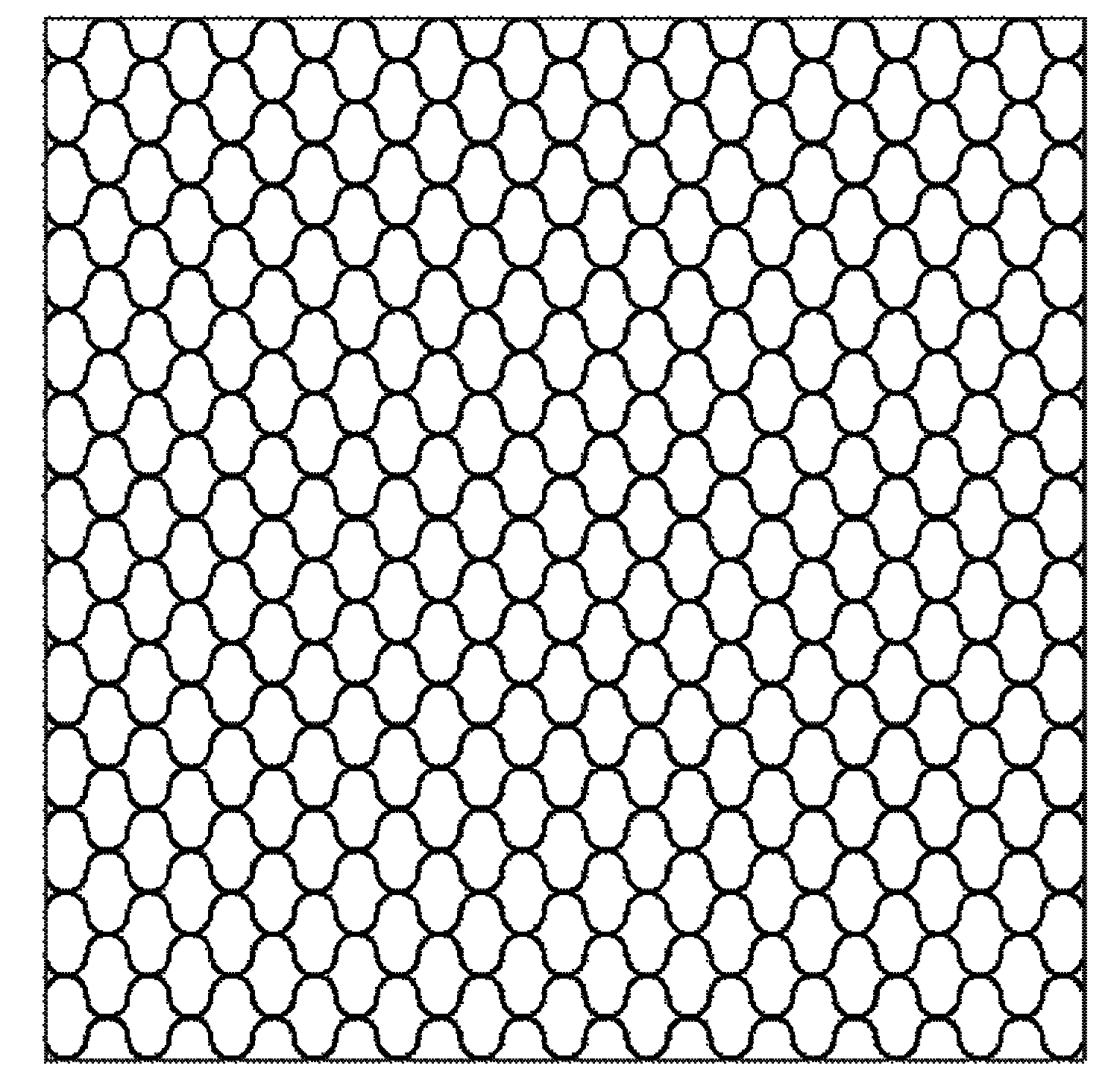

[0019] In this embodiment, 25 layers of titanium mesh are used. The titanium mesh is 400 mesh, the thickness of the titanium mesh is 0.2mm, and the size of the titanium mesh is: 500×500mm. The size of the corrugated plate corrugation is: the inner diameter is 19mm, the outer diameter is 20mm, that is, the wall thickness is 1mm. It can be seen from the above that at 1m 3 In the volume space, there are 8 corrugated plate catalyst modules with a surface area of 157m 2 . Since the framework used in the present invention is a 400 mesh titanium mesh, the calculated specific surface area has no reference significance, and the actual specific surface area is much higher than 157m 2 . The catalyst weight used in this embodiment is 0.07t / m 3 . Far lower than the same type of catalysts currently on the market, the weight of the current commercial corrugated plate catalyst is about 0.4t / m 3 .

[0020] From the above examples, it can be seen that under the same volume, the catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com