Chain scission and scraper plate fracture electronic alarming device for cleaning mechanism of coal feeder

A cleaning mechanism and alarm device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as downtime due to failure, high accumulation of scattered coal, and failure to remind users in time, so as to reduce probability and time, The effect of improving overall reliability and avoiding downtime due to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

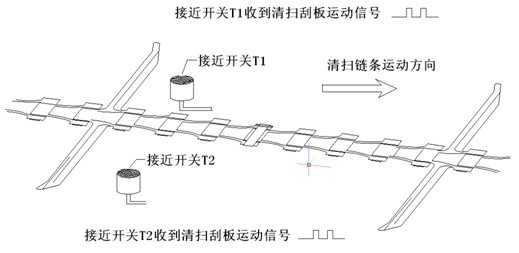

[0012] Such as figure 1 The schematic diagram of the cleaning chain movement of the coal feeder is shown. The proximity switches T1 and T2 installed side by side are respectively placed on both sides of the cleaning lotus. With the movement of the cleaning chain, the proximity switches T1 and T2 receive the pulse movement signal of the cleaning scraper.

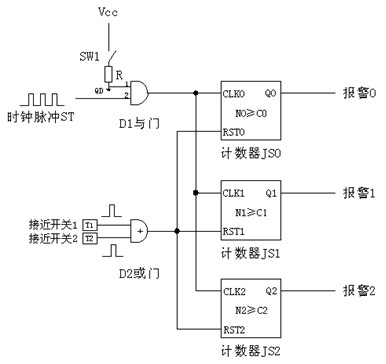

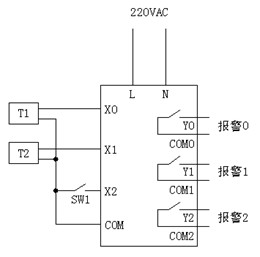

[0013] The control principle of the electronic alarm device for the broken chain of the cleaning mechanism of the coal feeder and the broken scraper is as follows: figure 2 As shown: the core part is composed of 3 counters (JS0, JS1, JS2), and the counting completion output of the 3 counters (Q0, Q1, Q2) is respectively used as an electronic alarm device for the chain breakage of the cleaning mechanism of the coal feeder and the breakage of the scraper. Output, the clock input of the counter (CLK0, CLK1, CLK2) is input by the cleaning mechanism start-up level signal QD and the standard clock signal ST (second pulse) through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com