Ultra-low-expansion glass-ceramic super-stable treatment method

A technology of stabilization treatment and glass-ceramics, applied in Sagnac effect gyroscopes, etc., can solve problems such as not being able to meet the ultra-stabilization treatment requirements of laser gyro resonator cavities, and achieve the goal of improving stabilization efficiency and reducing internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

[0021] The invention relates to an ultra-stabilization treatment method for ultra-low expansion glass-ceramics, in particular to an ultra-stabilization treatment method for a laser gyro resonant cavity that requires high stability.

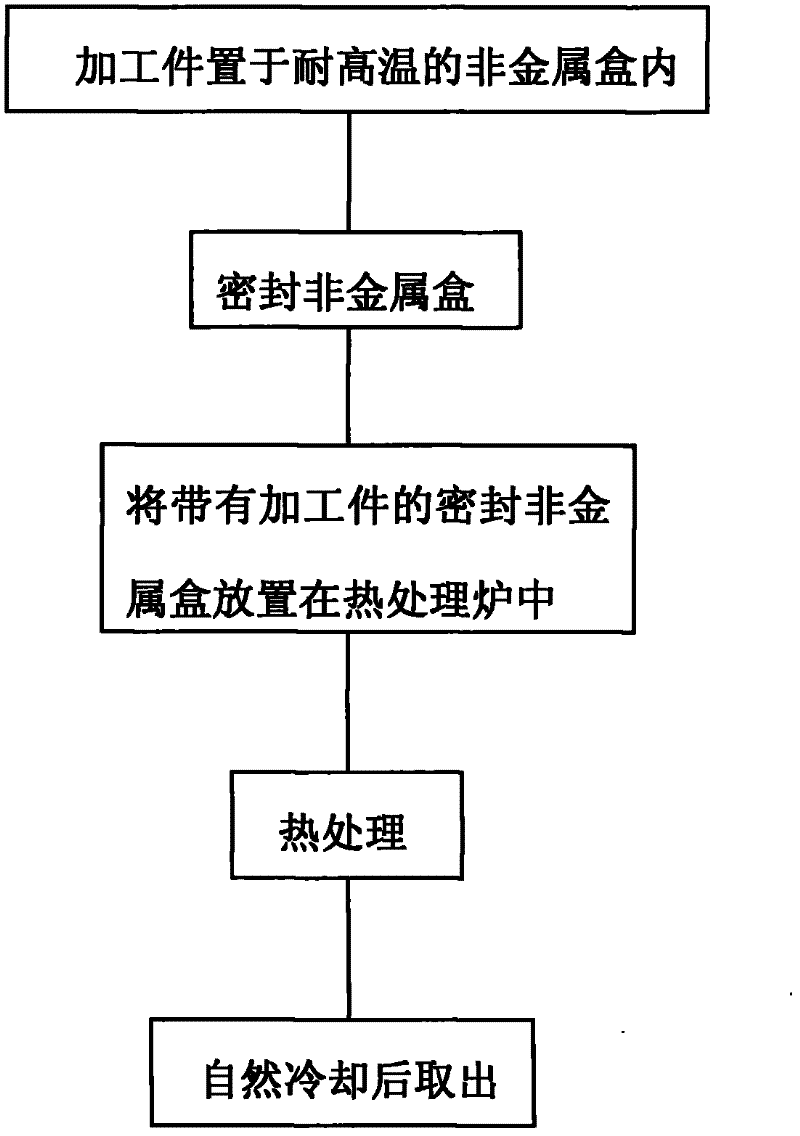

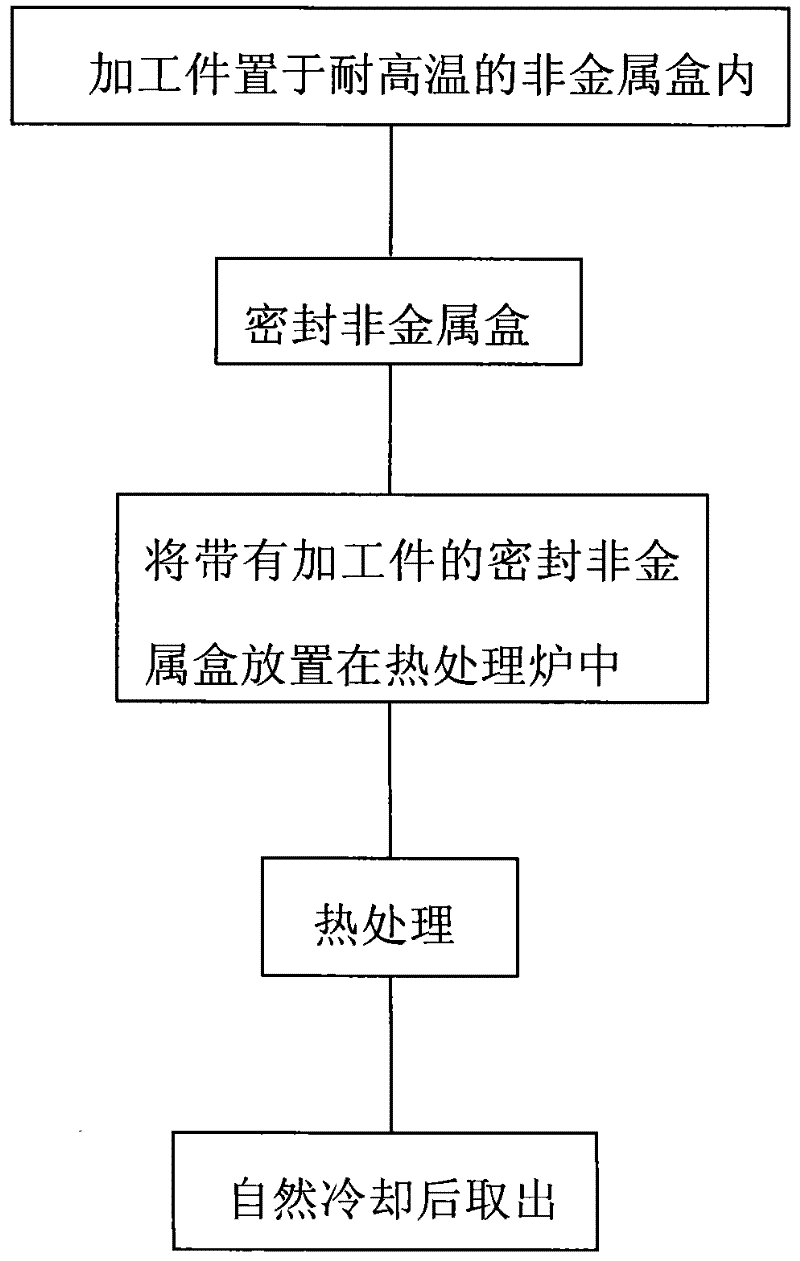

[0022] Concrete implementation steps of the present invention are as follows:

[0023] Step 1. Place the workpiece in a high temperature resistant non-metal box,

[0024] The size of the non-metallic box is large enough, so that the distance between each side of the workpiece and the inner layer of the non-metallic box is greater than 30mm, and the height of the workpiece and the bottom of the non-metallic box is 30mm and the diameter It is supported by a 10mm support block to ensure that during the temperature treatment process, most of the temperature conduction on the workpiece is realized through the gas in the box;

[0025] Step 2. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com