Polyimide precursor resin solution and film, laminated board and PCB

A technology of polyimide precursor and resin solution, which is applied in the direction of printed circuit, printed circuit parts, circuit substrate materials, etc., can solve the problems of excellent thermal characteristics, difficult long-term storage, high degree of polymerization, etc., and achieve excellent processability and storage Excellent stability and excellent balance of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

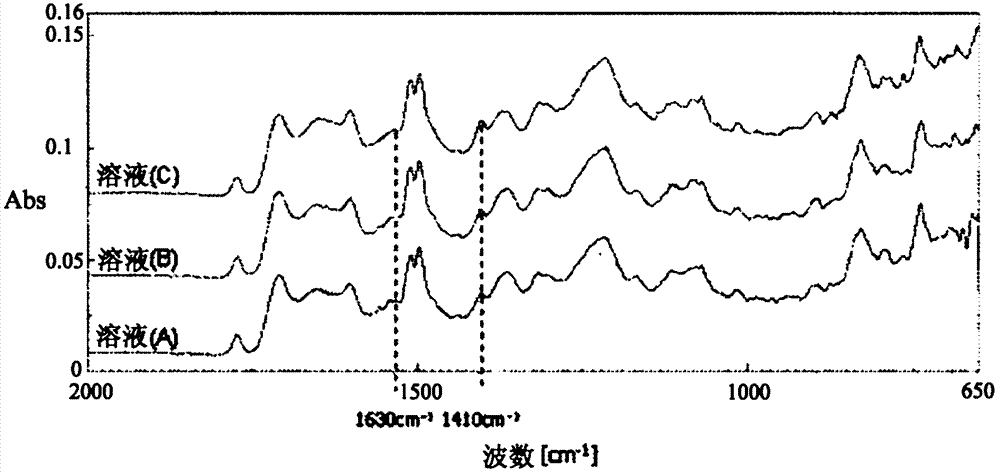

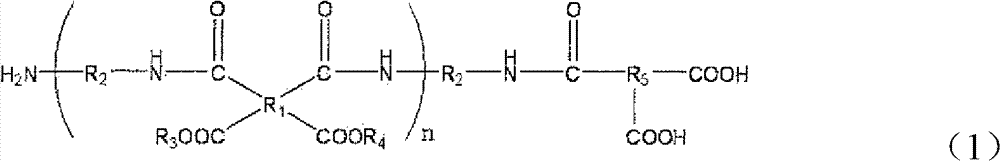

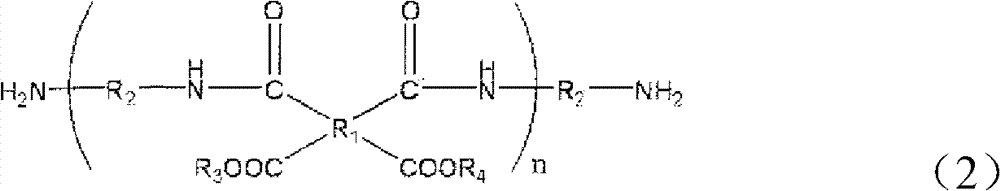

[0181] (1) Polymerization of the amine-terminated polyimide precursor resin represented by the following formula (2)'

[0182] [chemical formula 19]

[0183]

[0184] In the formula, R 1 It represents any one or more of the structures represented by the following formula (5).

[0185] [chemical formula 20]

[0186]

[0187] R 2 It represents any one or more of the structures represented by the following formula (6).

[0188] [chemical formula 21]

[0189]

[0190] 240 g of NMP was added to a 500 L flask as a polymerization solvent. Then, 11.982 g (0.1108 mol) of p-PDA and 7.389 g (0.0369 mol) of 4,4'-DAPE were added as a diamine component, and it stirred and melt|dissolved at 30 degreeC.

[0191] 37.543 g (0.1276 mol) of BPDA and 3.097 g (0.0142 mol) of PMDA were added gradually to the obtained solution as a tetracarboxylic dianhydride component. Then, by stirring at room temperature for 10 hours, a solution (A) containing the amine-terminated polyimide precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com