Spherical haydite matrix for constructed wetland and its preparation method

A technology for constructed wetlands and substrates, applied in chemical instruments and methods, clay products, and other household appliances, etc., can solve the problems of difficulty in maintaining long-lasting continuous operation of the constructed wetland treatment system, low phosphorus removal capacity, clogging, etc., and achieve good environmental benefits. and social benefits, saving economic costs, increasing the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the research on the preparation method of the constructed wetland matrix, the inventors carried out the following test process, so as to determine the optimal control parameters in the matrix preparation method.

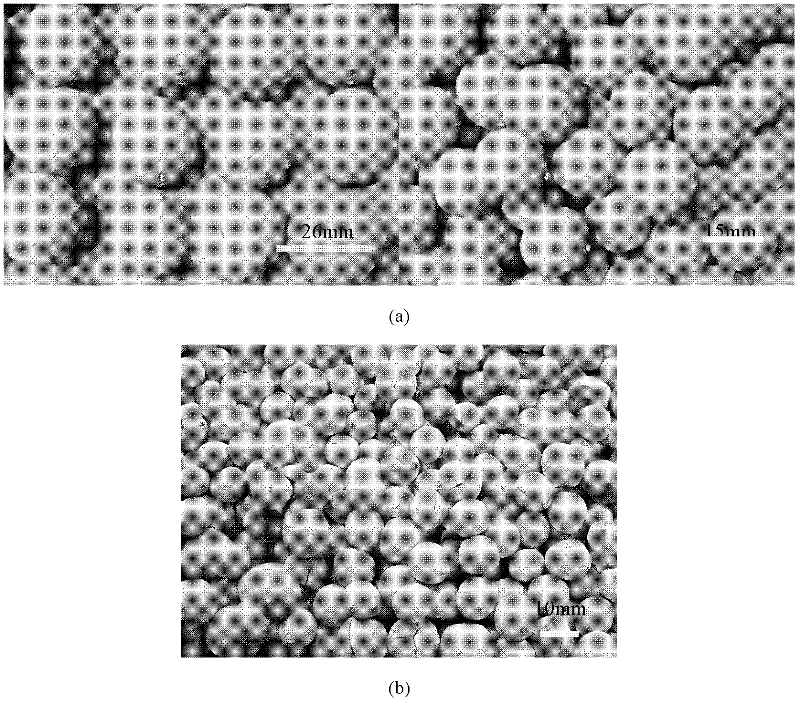

[0025] (1) Select raw materials and make ceramsite

[0026] The applicant has found through research that the terminal coagulated sludge of the water supply plant will form many micro-pores after firing, and this structure has a strong ability to adsorb and remove pollutants. At the same time, there are a large amount of coagulant residues such as aluminum and iron in the terminal coagulation sludge, which has good precipitation and removal performance for phosphate in sewage; therefore, the terminal coagulation sludge of the water supply plant is selected as the raw material of the matrix. The sludge in this experiment was taken from the terminal sludge of Qujiang Water Plant in Xi'an City. The agent added to the coagulation and sedimentation process of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com