Biological fertilizer special for organic peanuts and preparation method thereof

A bio-fertilizer and peanut technology, applied in the field of fertilizer production, to achieve the effects of increasing yield, increasing economic benefits, and promoting high yield of peanuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

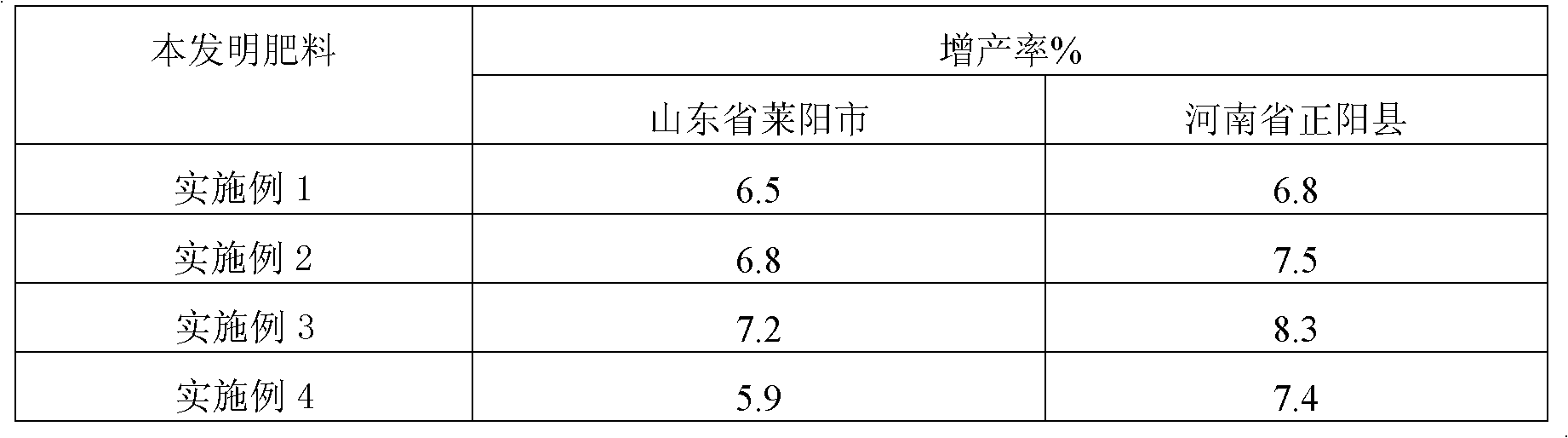

Examples

Embodiment 1

[0037] Embodiment 1: special biological fertilizer for organic peanuts, the raw material components are as follows:

[0038] 400 kg of degraded peanut oil residue, 600 kg of peanut straw, and 5 kg of microbial agent EM composite agent.

[0039] The preparation method steps are as follows:

[0040] (1) Preparation of Bacillus subtilis fermentation liquid and Yarrowia lipolytica fermentation liquid

[0041] Take 20 grams of peeled potatoes, add 100 grams of water and boil for 20 minutes, filter through gauze, add water to the filtrate to 100 grams, then add 1.5 grams of glucose and 0.2 grams of peptone, heat until all ingredients are dissolved, and sterilize under 0.11 MPa pressure for 30 minutes , prepared into a liquid culture medium, the activated Bacillus subtilis and Yarrowia lipolytica were cultured for 2 days respectively in shake flasks at 28°C and 180 rpm; 20 kg of potatoes, 0.8 kg of glucose, 3.0 kg of oil residue, and 100 kg of water were cultured in a fermenter at ...

Embodiment 2

[0044] Embodiment 2: special bio-fertilizer for organic peanuts, the mass parts of raw materials are as follows:

[0045] 500 kg of degraded peanut oil residue, 500 kg of peanut straw, and 4 kg of microbial agent EM composite agent.

[0046] The preparation method is the same as in Example 1.

Embodiment 3

[0047] Embodiment 3: special bio-fertilizer for organic peanuts, the mass parts of raw materials are as follows:

[0048] 600 kg of degraded peanut oil residue, 400 kg of peanut straw, and 3 kg of microbial agent EM composite agent.

[0049] The preparation method steps are as follows:

[0050] (1) The preparation method of Bacillus subtilis fermentation liquid and Yarrowia lipolytica fermentation liquid is the same as that in Example 1.

[0051] (2) Get 70 kilograms of Bacillus subtilis fermentation liquid, 60 kilograms of Yarrowia lipolytica fermentation liquid and add in 550 kilograms of peanut oil residues, adjust moisture content 54wt%, pH6.8, fully mix, control material temperature 40 ℃, place 6 Hour. Heat up, count when the temperature rises to 100°C, and keep it for 30 minutes. Degradation of peanut oil residue was obtained.

[0052] (3) Take 400 kg of peanut stalks crushed to a length of 0.5 cm, mix with 600 kg of peanut oil residue degradation product prepared in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com