Method for preparing high-intensity three-dimensional chitosan porous bracket

A technology of porous scaffold and chitosan, which is applied in the fields of medical science and prosthesis, can solve the problems of poor connectivity and poor mechanical properties of three-dimensional chitosan porous scaffold, and achieve the effects of low cost, easy promotion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

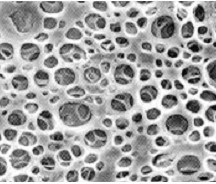

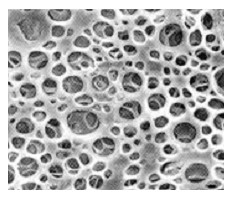

Image

Examples

Embodiment 1

[0033] A preparation method of a high-strength three-dimensional chitosan porous support, comprising the steps of:

[0034] (1) Preparation of chitosan and n-amyl alcohol emulsion

[0035] ①. Prepare 3% (W / V) chitosan acetate solution

[0036] First, measure 1ml of acetic acid and add it to a 100ml volumetric flask to make a constant volume to obtain a 1% (V / V) acetic acid solution, then weigh 3g of chitosan, and add it to a 1% (V / V) acetic acid solution to obtain 3% ( W / V) chitosan acetate solution;

[0037] The degree of deacetylation of the chitosan used is ≥91%;

[0038] ②, 1% (v / v) glutaraldehyde aqueous solution

[0039] Measure 1ml of pure glutaraldehyde and add distilled water to make up to 100ml to get 1% (v / v) glutaraldehyde aqueous solution, store at 4°C for later use;

[0040] ③ Chitosan and n-pentanol emulsion

[0041] Take 10ml of the 3% (W / V) chitosan acetic acid solution obtained in the above step ①, and carry out magnetic stirring, gradually add 20ml of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com