Polypropylene composition for solar battery and preparation method thereof

A technology of polypropylene composition and solar cell, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as poor weather resistance, poor UV blocking performance, and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

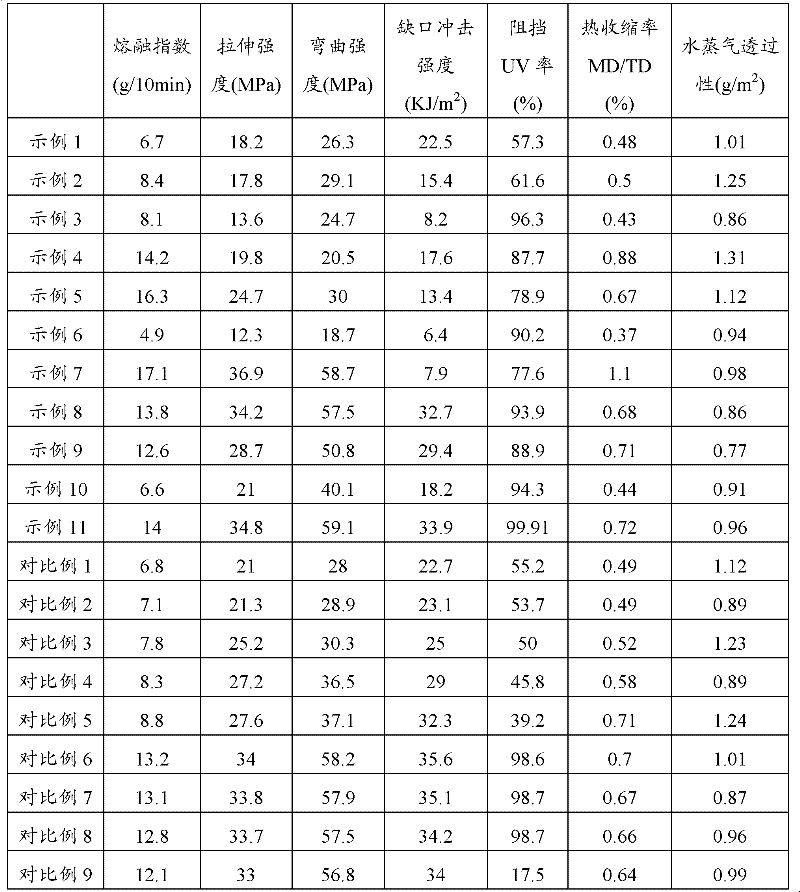

Examples

preparation example Construction

[0035] According to one embodiment, the preparation method may include: 50-100 parts by weight of at least one of homopolypropylene and copolymerized polypropylene, 0-50 parts by weight of inorganic filler, 15-25 parts by weight of 0.2-30 parts by weight of antioxidant, 0.5-20 parts by weight of toughening agent and 0.1-10 parts by weight of modified polymer are blended. This melt blending can be performed using known equipment such as a general mixer, a twin-screw extruder, a single-screw extruder, an open mill, an internal mixer, and the like. During the blending process, an appropriate amount of compatibilizer can be added as needed.

[0036] According to another embodiment, instead of the anti-ultraviolet auxiliary agent, the precursor of the anti-ultraviolet auxiliary agent can be blended with other components used to form the polypropylene composition, and then the precursor of the anti-ultraviolet auxiliary agent is blended under appropriate conditions (such as heating...

example 12

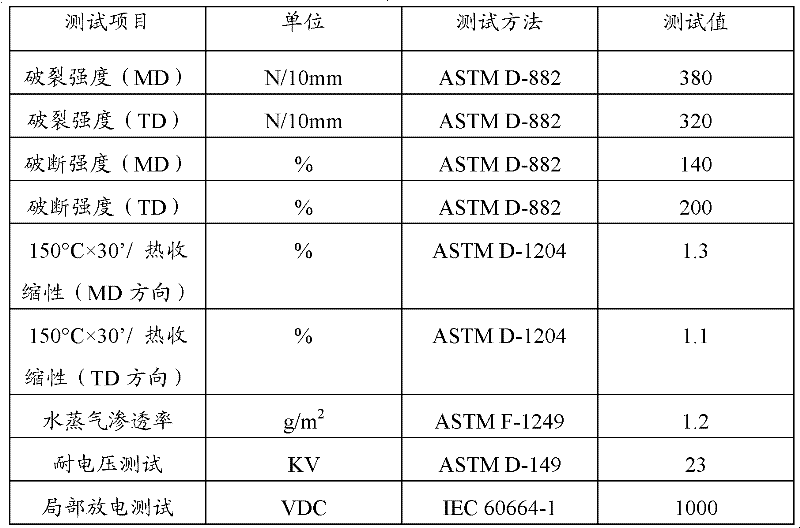

[0056] Example 12: Manufacture of insulating strips for solar cells

[0057] Prepared using a polypropylene composition film according to Example 1, a PET film with a thickness of 150 μm, two EVA adhesive layers each with a thickness of 10 μm figure 1 The solar cells shown use insulating strips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com