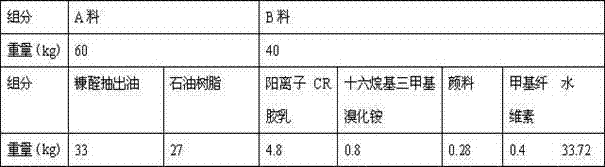

Cation type aqueous colored pavement crack sealing material and preparation process thereof

A pavement crack, cationic technology, applied in the direction of roads, roads, pavement details, etc., can solve the problems of easy cracking again, low bonding strength, environmental pollution, etc., to achieve good adhesion, not easy to fade, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

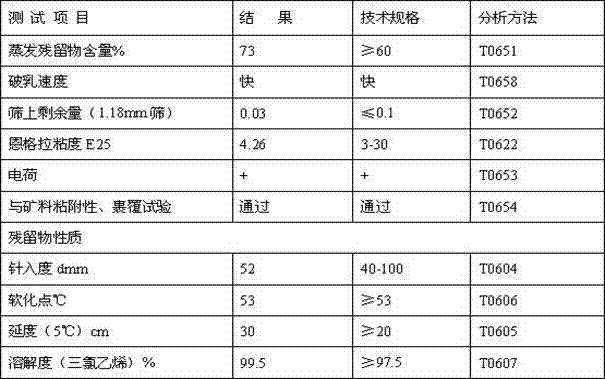

[0022] The raw materials used to produce 100kg cationic water-based colored pavement crack sealant are as follows:

[0023]

[0024] Its preparation process is as follows:

[0025] Preparation of material A: first clean up the mixing equipment, then add furfural oil with a weight of 30kg and petroleum resin with a weight of 30kg in the mixing equipment. During the addition process, the mixing equipment is constantly stirring, and the mixture is heated to 170°C, stirring at 170°C for 60 minutes to prepare 60kg of material A cement after shearing;

[0026] The preparation of B material: the cationic CR latex that weight is 4kg, the methyl cellulose that weight is 0.4kg as emulsifier and the pigment that weight is 0.28kg, weight is the cetyltrimethylammonium bromide of 1.2kg, Mix and stir water with a weight of 34.12kg to prepare 40kg of material B soap;

[0027] First will follow the steps The prepared 60kg material A is heated to 140°C, follow the steps The prepa...

Embodiment 2

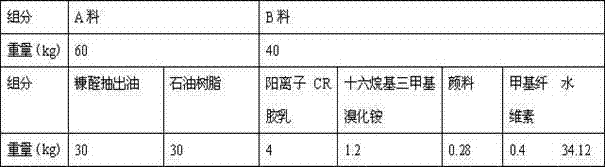

[0029] The raw materials used to produce 100kg cationic water-based colored pavement crack sealant are as follows:

[0030]

[0031] Its preparation process is as follows:

[0032] Preparation of material A: first clean up the mixing equipment, then add furfural oil with a weight of 33kg and petroleum resin with a weight of 27kg in the mixing equipment. During the addition, the mixing equipment is constantly stirring, and the mixture is heated to 170°C, stirring at 170°C for 60 minutes to prepare 60kg of material A cement after shearing;

[0033] The preparation of B material: be that the cetyltrimethylammonium bromide that is 0.8kg by weight is the pigment that is 0.28kg by weight, the cationic CR latex that is 4.8kg by weight, the methyl cellulose that is 0.4kg by weight , the water mixing and stirring that weight is 33.72kg prepares 40kg of B material soap liquid;

[0034] First will follow the steps The prepared 60kg material A is heated to 140°C, follow the s...

Embodiment 3

[0036] The raw materials used to produce 100kg cationic water-based colored pavement crack sealant are as follows:

[0037]

[0038] Its preparation process is as follows:

[0039] Preparation of material A: first clean up the mixing equipment, then add furfural oil with a weight of 31.8kg and petroleum resin with a weight of 28.2kg to the mixing equipment. Heat to 170°C, stir at 170°C for 60 minutes, and prepare 60kg of material A cement after shearing;

[0040] The preparation of B material: with the cetyltrimethylammonium bromide that is 0.8kg by weight as emulsifier and the pigment that is 0.28kg by weight, the cationic CR latex that is 4kg by weight, the methylcellulose that is by 0.4kg by weight, 40kg of B material soap liquid is prepared by mixing and stirring water with a weight of 34.52kg;

[0041] First will follow the steps The prepared 60kg material A is heated to 140°C, follow the steps The prepared 40kg material B was heated to 60°C, and then the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com