Silicon grease composition with high thermal dissipation and preparation method thereof

A composition and high heat dissipation technology, which is applied in the field of thermally conductive polymer materials, can solve the problems of high heat dissipation silicone paste layer being easy to dry and pulverize, unable to use screen printing, poor viscosity and rheological properties, etc., to achieve the production process Simple and environmentally friendly, not easy to dry and powder, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

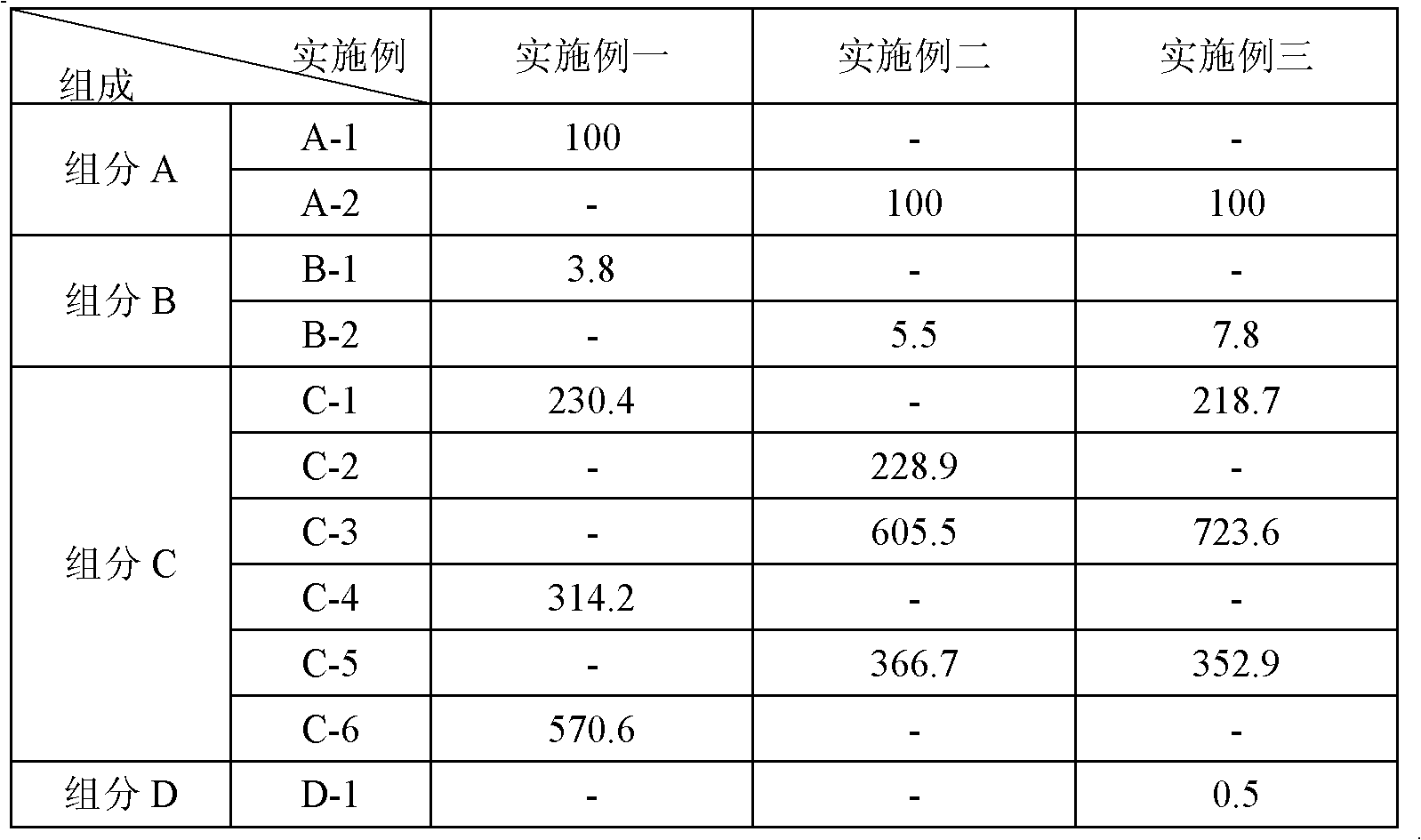

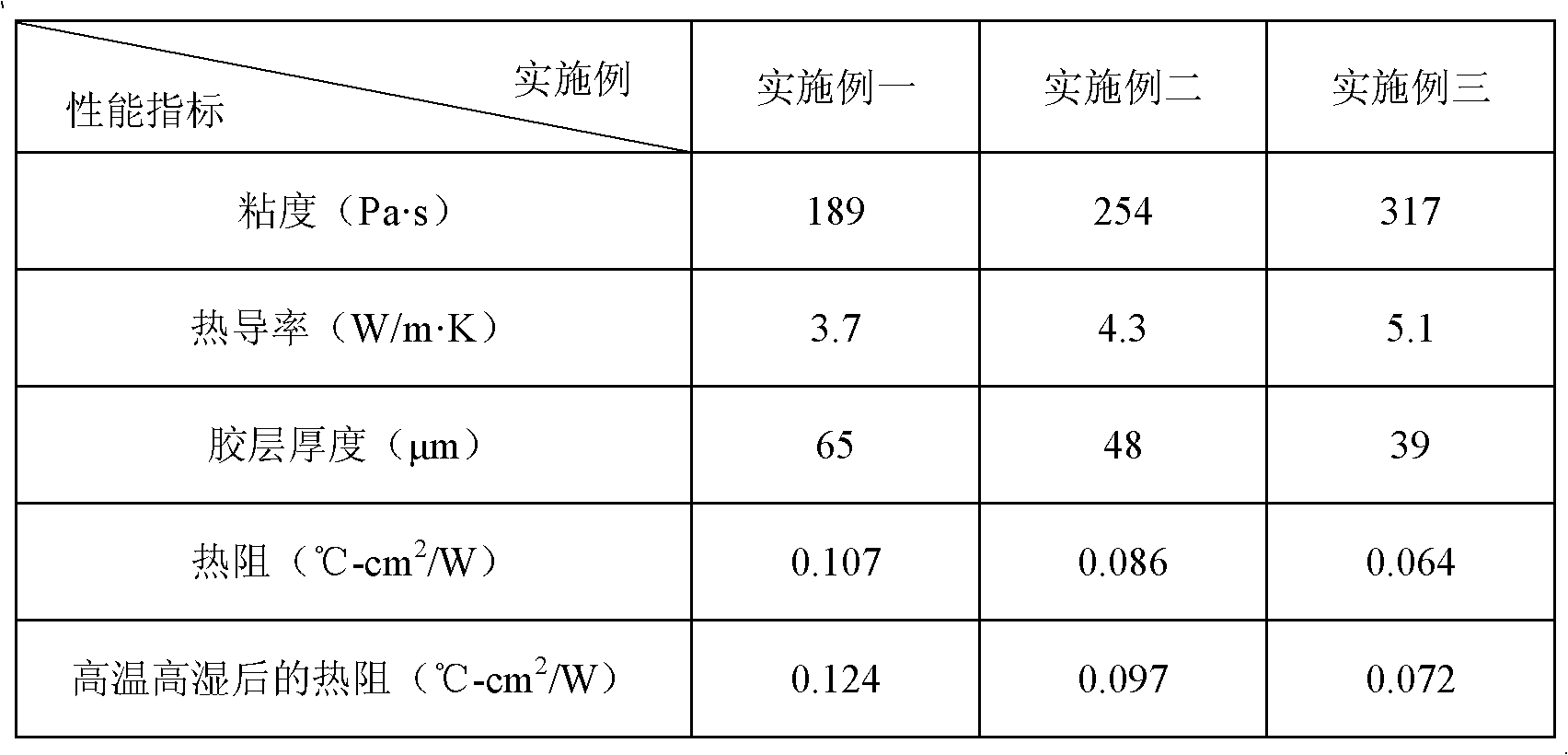

Examples

Embodiment Construction

[0032] R in component A and component B of the present invention 1 , R 3 , R 4 , R 5 It is straight-chain alkyl, branched-chain alkyl, cycloalkyl, alkenyl, aryl, aralkyl, epoxy. straight-chain alkyl such as methyl, ethyl, propyl, hexyl, octyl or dodecyl; branched-chain alkyl such as isopropyl, isobutyl, tert-butyl or 2-ethylhexyl; cyclopentyl Cycloalkyl such as base or cyclohexyl; Alkenyl such as vinyl or allyl; Aryl such as phenyl or tolyl; Aralkyl such as 2-phenylethyl or 2-methyl-2-phenylethyl ; 2,3-epoxy propoxypropyl and other epoxy groups. Methyl, octyl, tert-butyl or phenyl are preferred.

[0033] R 2 Straight chain alkyl such as methyl, ethyl, propyl, hexyl, octyl or dodecyl; branched alkyl such as isopropyl, isobutyl, tert-butyl or 2-ethylhexyl; methoxy alkoxyalkyl groups such as ethyl and methoxypropyl; alkenyl groups such as vinyl and allyl; and acyl groups such as acetyl and octanoyl. R 6 Straight-chain alkyl groups such as methyl, ethyl, propyl, hexyl, oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com