Treatment method of microalgae

A treatment method, microalgae technology, applied in the direction of microbial dissolution, etc., can solve the problems of needing to add protective agents, high operating pressure, etc., and achieve the effect of low operating pressure and temperature, not easy to destroy, and high wall breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

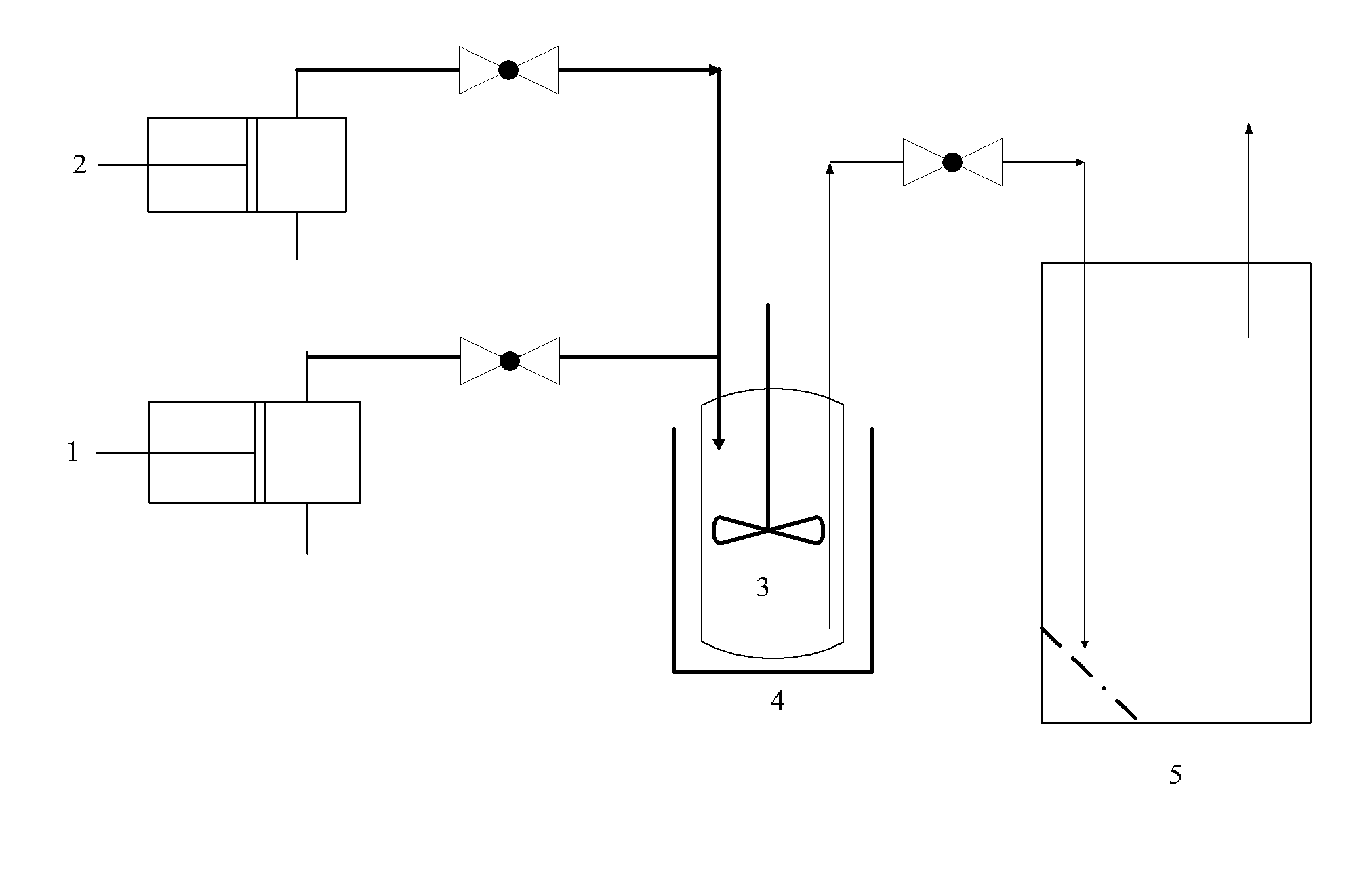

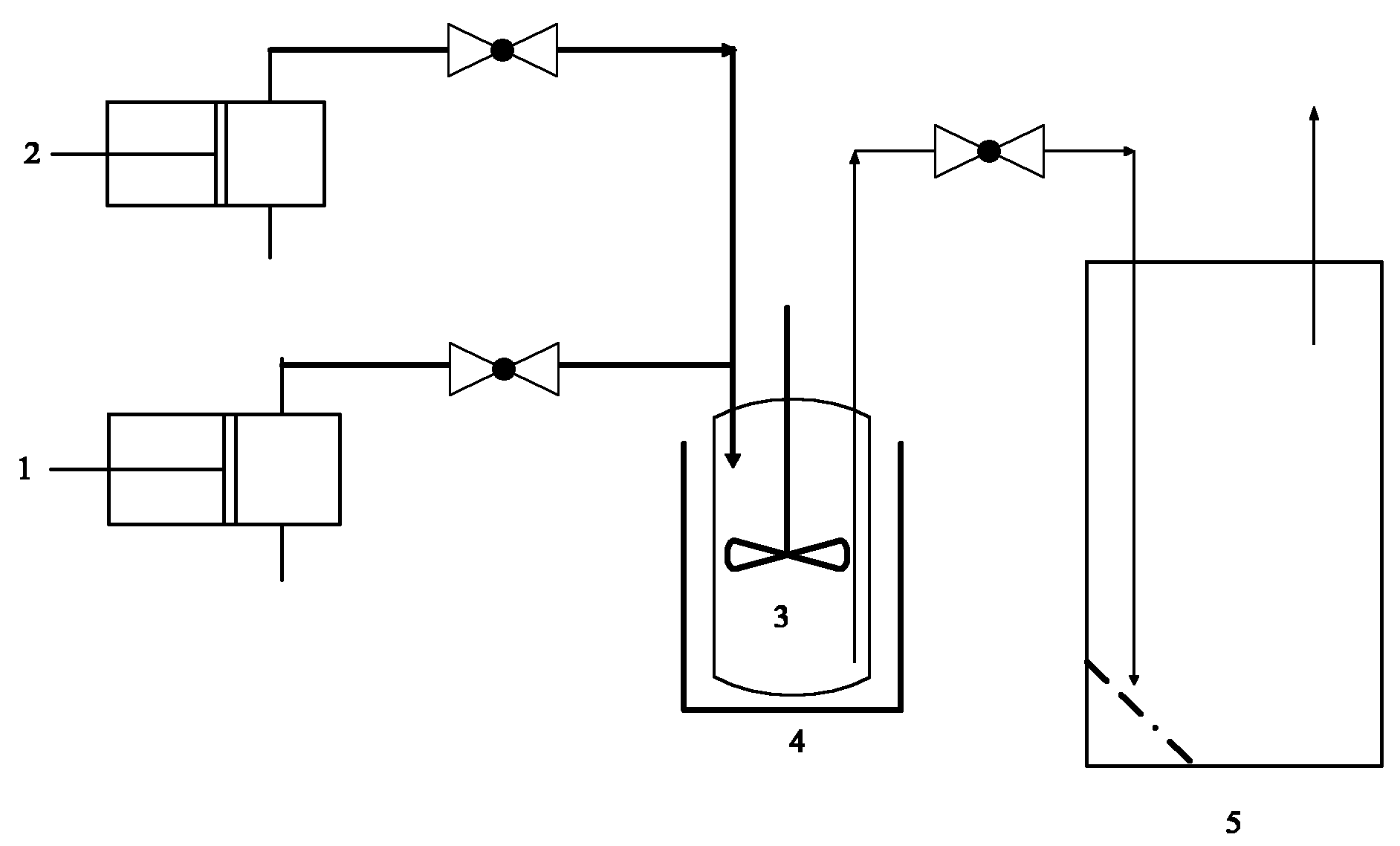

Method used

Image

Examples

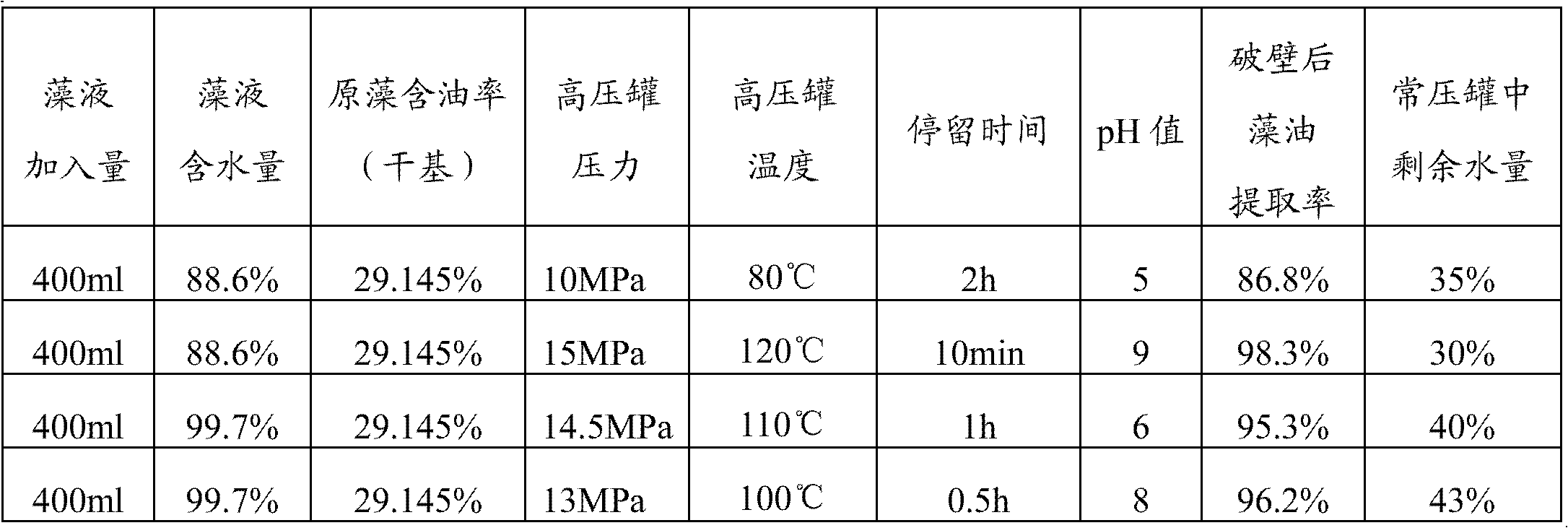

Embodiment 1

[0029] Get water content and be 88.6% chlorella (chlorella) (prototheca oil content rate is 29.145% (dry basis)) algae liquid 400ml, then in chlorella algae liquid, drop acetic acid, adjust Ph value to be 5. Add the adjusted algae liquid into the high-pressure tank, then add high-pressure nitrogen into the high-pressure tank, so that the pressure in the high-pressure tank is maintained at 8MPa. Heat the high-pressure tank to 80°C, while the pressure rises to 10MPa, and maintain this condition for 2h. Then the material is discharged into the normal temperature and pressure tank, and the broken microalgae and algae oil remain in the normal pressure tank, and at the same time, a large amount of water is carried out of the normal pressure tank by nitrogen to achieve the effect of drying part of the microalgae. Then, the algae oil extraction rate was tested for the product collected in the vacuum tank, and the algae oil extraction rate was 86.8% after the wall was broken.

Embodiment 2

[0031] Get water content and be 88.6% different oxygen chlorella (chlorella vulga) (prototheca oil content rate is 29.145% (dry basis)) algae liquid 400ml, then drop sodium hydroxide solution in the chlorella algae liquid, adjust Ph The value is 9. Add the adjusted algae liquid into the high-pressure tank, then add high-pressure nitrogen into the high-pressure tank, so that the pressure in the high-pressure tank is maintained at 12MPa. Heat the high-pressure tank to 120°C while increasing the pressure to 15MPa, and maintain this condition for 10 minutes. Then the material is discharged into the normal temperature and pressure tank, and the broken microalgae and algae oil remain in the normal pressure tank, and at the same time, a large amount of water is carried out of the normal pressure tank by nitrogen to achieve the effect of drying part of the microalgae. Then, the algae oil extraction rate was tested for the product collected in the vacuum tank, and the algae oil extrac...

Embodiment 3

[0033]Get 400ml of chlorella vulga (chlorella vulga) (Prototheca oil content rate 29.145% (dry basis)) algae liquid that water content is 99.7%, add sulfuric acid dropwise in chlorella algae liquid then, adjust Ph value to be 6 . Add the adjusted algae liquid into the high-pressure tank, then add high-pressure nitrogen into the high-pressure tank, so that the pressure in the high-pressure tank is maintained at 12MPa. The high-pressure tank was heated to 110°C, and the pressure was raised to 14.5MPa at the same time, and maintained under this condition for 1h. Then the material is discharged into the normal temperature and pressure tank, and the broken microalgae and algae oil remain in the normal pressure tank, and at the same time, a large amount of water is carried out of the normal pressure tank by nitrogen to achieve the effect of drying part of the microalgae. Then, the algae oil extraction rate was tested for the product collected in the vacuum tank, and the algae oil e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com