Multilayer composite pipeline

A multi-layer composite and pipeline technology, applied in the impact-resistant multi-layer composite pipeline, corrosion-resistant, wear-resistant, low-cost fields, can solve the problems of fragility, single pipeline function, complex processing of ceramic materials, etc., to improve wear resistance. performance, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

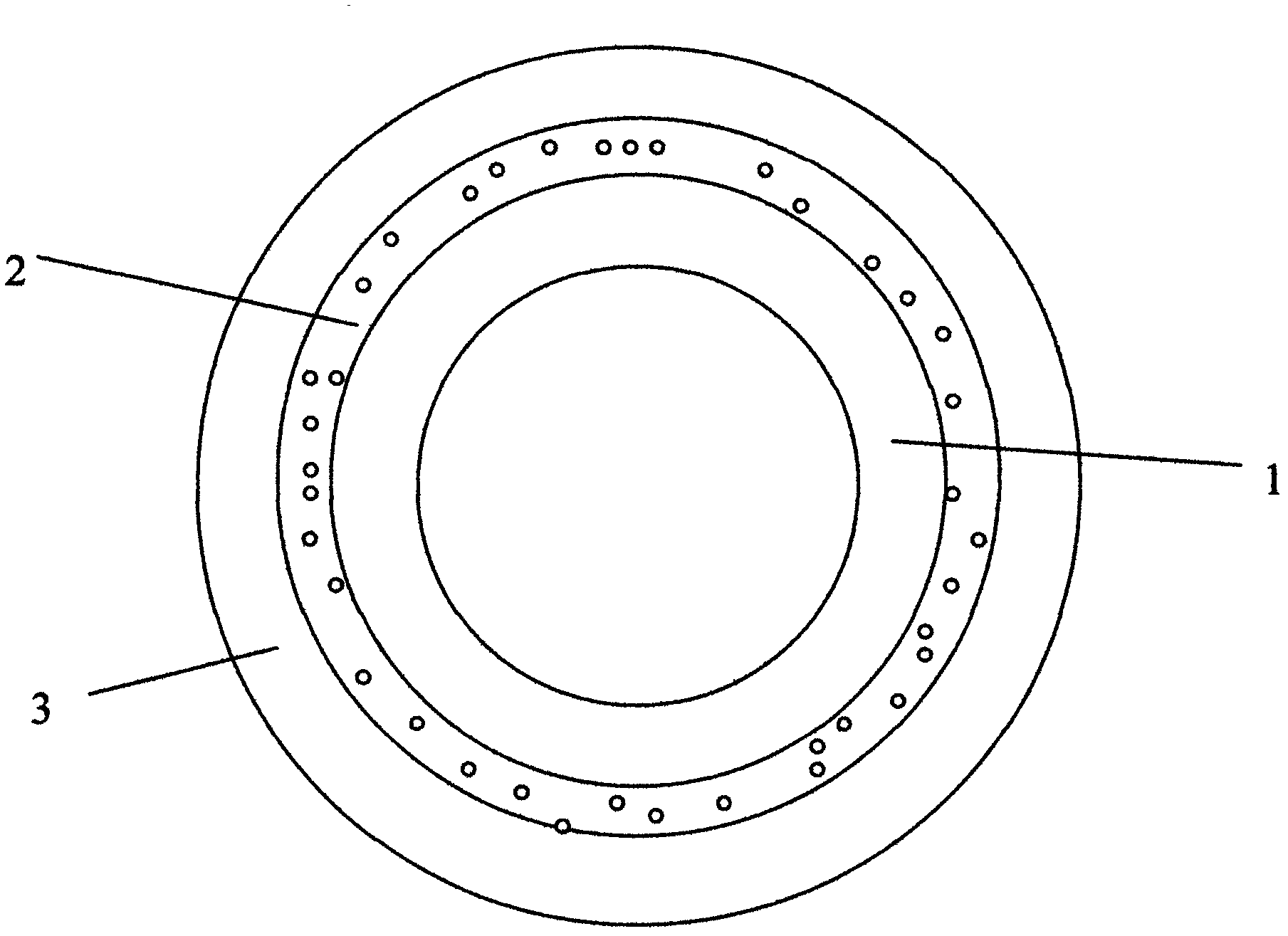

Image

Examples

Embodiment 1

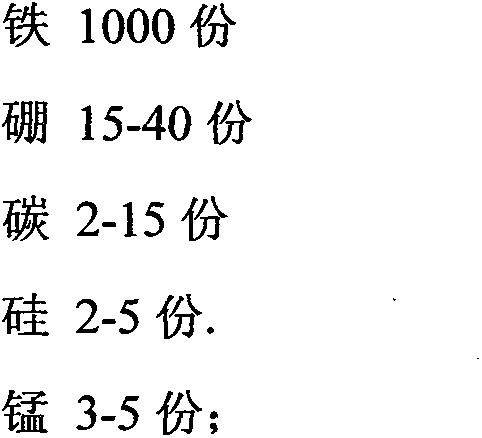

[0029] The inner layer of the multi-layer composite pipe is composed of:

[0030] Iron 1000 parts,

[0031] Boron 15 parts,

[0032] Carbon 2 parts,

[0033] Silicon 2 parts,

[0034] Manganese 3 parts;

[0035] The middle layer of the multilayer composite pipe is foamed plastic;

[0036] The main component of the outer layer of the multilayer composite pipe is PVC;

[0037] The inner layer and the middle layer of the multi-layer composite pipe, and the middle layer and the outer layer are all fixed by thermal glue bonding.

Embodiment 2

[0039] The inner layer of the multi-layer composite pipe is composed of:

[0040] Iron 1000 parts,

[0041] Boron 40 parts,

[0042] Carbon 15 parts,

[0043] Silicon 5 parts,

[0044] Manganese 5 parts;

[0045] The middle layer of the multilayer composite pipe is foamed plastic;

[0046] The main component of the outer layer of the multilayer composite pipe is ultra-high molecular weight polyethylene;

[0047] The inner layer and the middle layer of the multi-layer composite pipe, and the middle layer and the outer layer are all fixed by thermal glue bonding.

Embodiment 3

[0049] The inner layer of the multi-layer composite pipe is composed of:

[0050] Iron 1000 parts,

[0051] Boron 30 parts,

[0052] Carbon 8 parts,

[0053] Silicon 4 parts,

[0054] Manganese 4 parts;

[0055] The middle layer of the multilayer composite pipe is foamed plastic;

[0056] The main component of the outer layer of the multilayer composite pipe is PVC;

[0057] The inner layer and the middle layer of the multi-layer composite pipe, and the middle layer and the outer layer are all fixed by thermal glue bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com