Optical condensation solar heat collector used at low temperature

A technology of concentrating solar energy and heat collectors, applied in the field of solar energy utilization, can solve the problems of reduced power generation efficiency, inability to use non-vacuum heat collector tubes, large heat loss, etc., to achieve the effect of convenient application and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

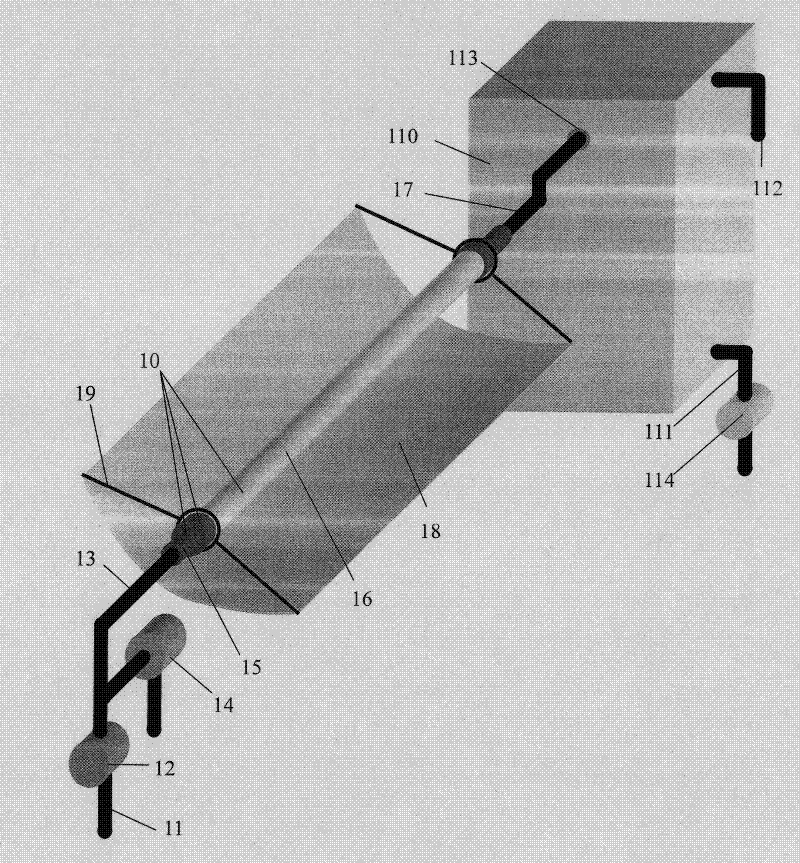

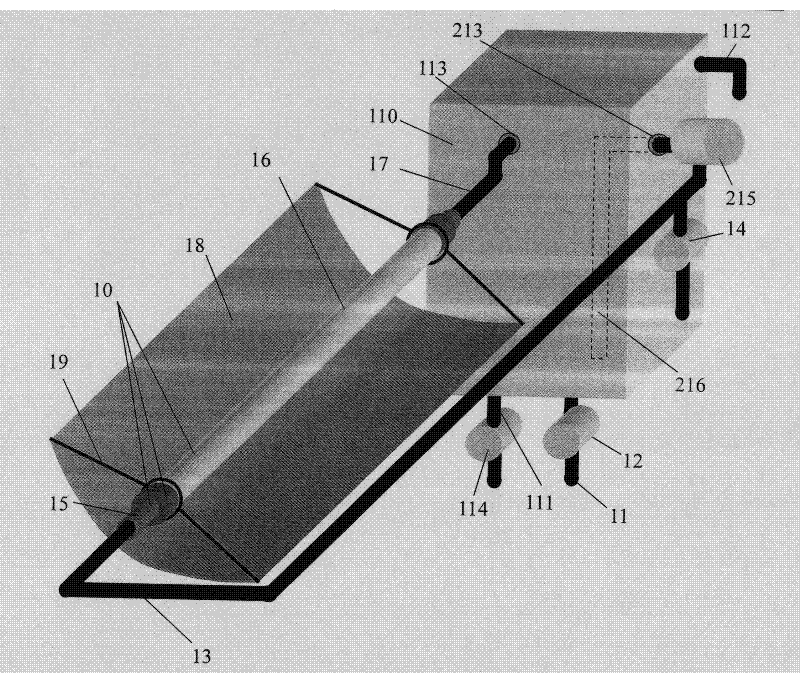

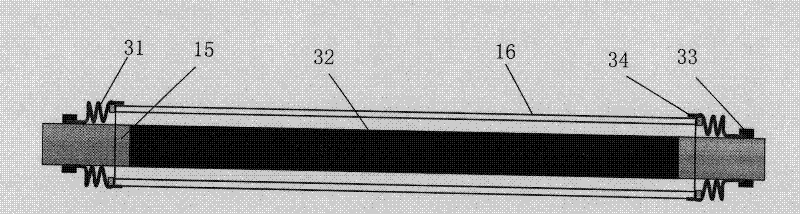

Method used

Image

Examples

Embodiment 1

[0024] Concentrating solar collectors for low temperature with non-circulating structure, using a 2-meter-diameter concentrator, a stainless steel collector tube inner tube with an outer diameter of 70 mm, coated with black chrome sunlight absorbing layer; the outer tube of the collector tube is made of borosilicate glass, with a diameter of 100 mm. The effective length of the heat collecting tube is 4 meters, and the volume of the water tank is 500 liters. In the 40-50 north latitude area, the system can provide 250 liters of warm water at 60 degrees when the winter solstice is sunny.

Embodiment 2

[0026] Similar to Example 1, but with a cyclic structure.

Embodiment 3

[0028] Concentrating solar collector for low temperature with non-circulating structure, using a 2-meter-caliber concentrating mirror, and a stainless steel collector tube with an outer diameter of 70 mm, which is coated with Mo-Al 2 o 3The sunlight absorbing layer; the outer tube of the heat collecting tube is made of borosilicate glass with a diameter of 100mm. The effective length of a single tube of the heat collecting tube is 4 meters, and two tubes are connected in series to form two heat collectors with a length of 8 meters each, and the volume of the common water tank is 2000 liters. The sunlight intensity detector, the outdoor temperature sensor, the water level sensor in the water tank, the water tank temperature sensor etc. share a set, the water temperature sensor on the water outlet connecting pipe is set separately, and the water injection valve is controlled separately. In the area of 40-50 north latitude, the system can provide 1200 liters of 60-degree warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com