Ultrasonic transducer device for geometric shape array of planar corrosive defect

A technology of ultrasonic transducers and geometric shapes, applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problems of low dynamic scanning efficiency and low configuration accuracy, and achieve simple and easy practical application Easy to use, high application value, and easy to modularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

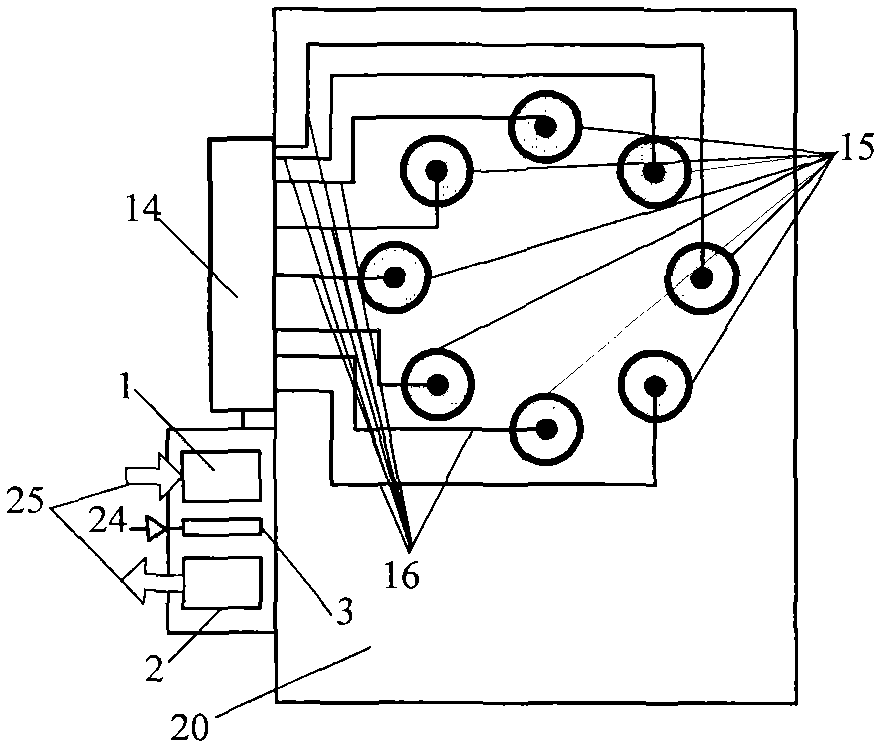

[0037] combine figure 2 , image 3 , Figure 4 One embodiment of the present invention will be described.

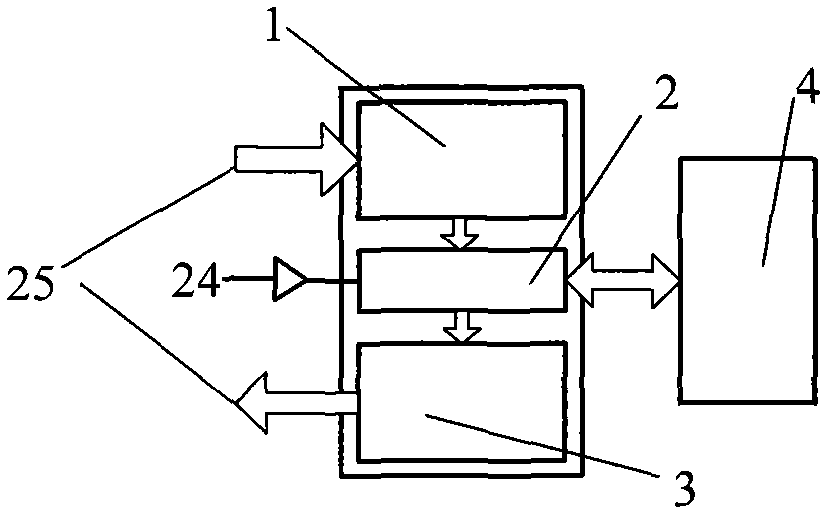

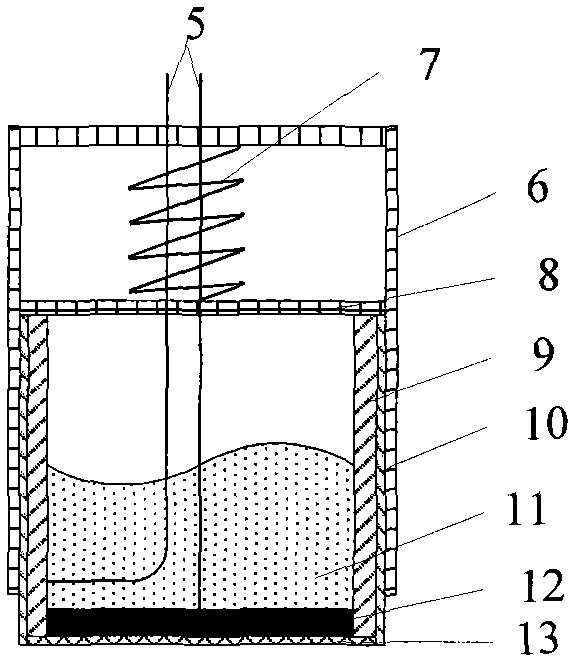

[0038] The present invention includes an excitation signal conditioning module 1, a multi-way switch 2, a receiving signal conditioning module 3, a piezoelectric transducer assembly (including a sliding sleeve 6, a preload spring, a transducer housing (8, 9, 10), a connecting Core wire 5, piezoelectric wafer 12, matching layer 13, backing layer 11), fixing bracket 20, external connecting wire 16, multi-way switch control wire 24, excitation and receiving signal wire 25.

[0039] refer to figure 2 As shown in the positional relationship, the matching layer 13 and the piezoelectric crystal sheet 12 are pasted together with glue, the piezoelectric crystal sheet 12 and the matching layer 13 are combined and installed at the lowermost end of the transducer, and the backing layer 11 is installed on the In the airtight cavity closed by the combination of the transducer no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com