Manufacturing method of ultra-high speed transmission data line and ultra-high speed transmission data line

A data transmission, ultra-high-speed technology, applied in the direction of cable/conductor manufacturing, conductors, insulated cables, etc., can solve the problems of unreasonable product structure layout, no performance and price ultra-high-speed transmission data lines, etc., to achieve enhanced anti-interference ability, The effect of technical content improvement and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

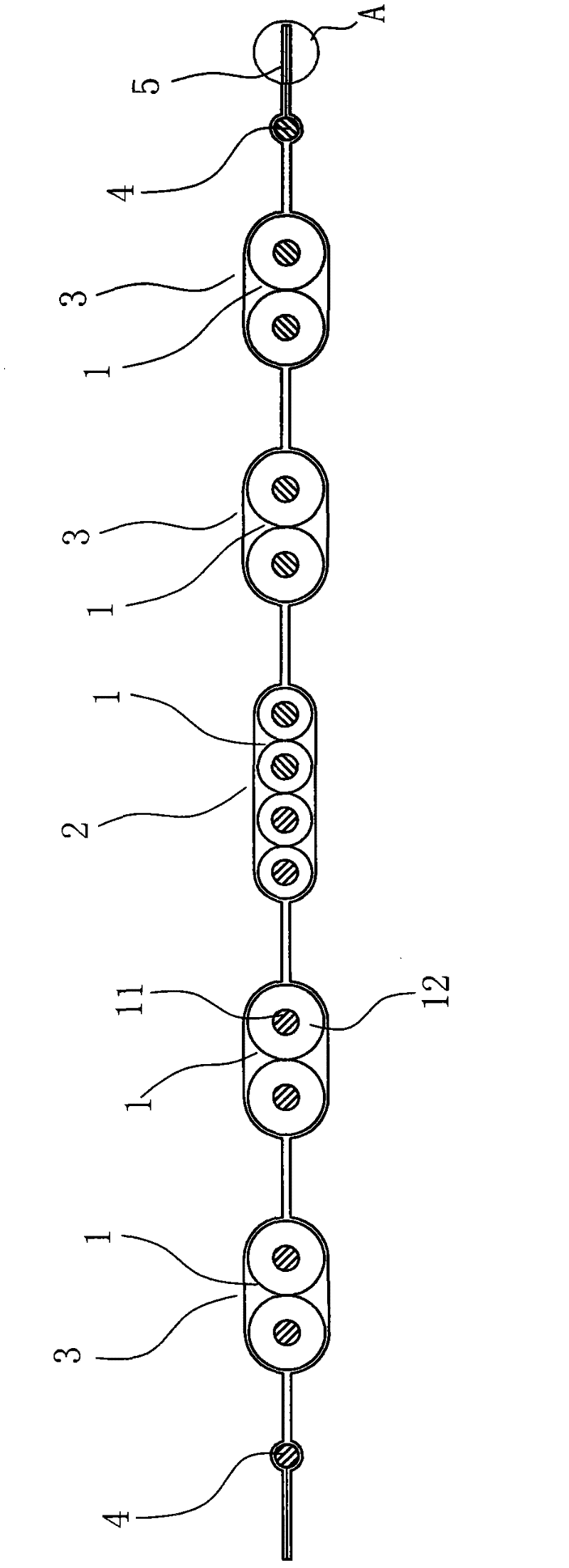

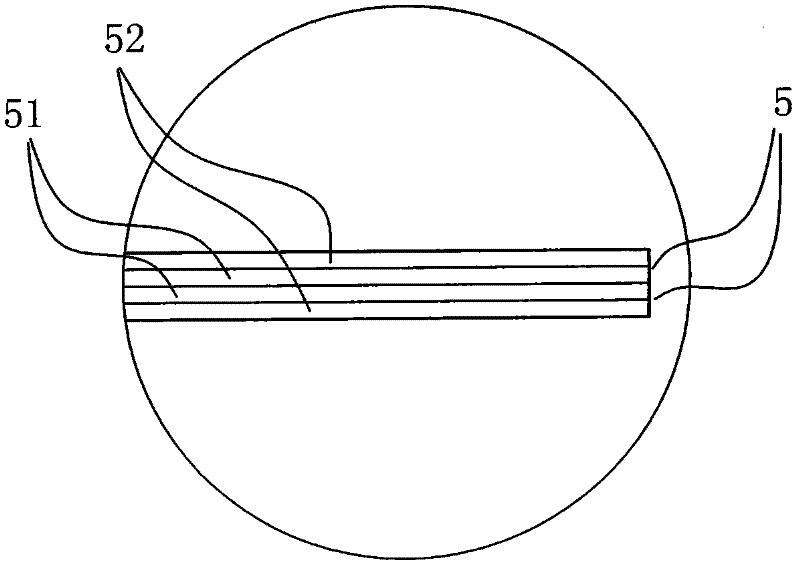

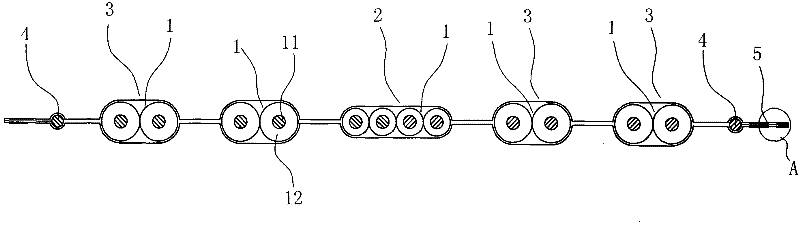

[0026] Example: see figure 1 and figure 2 , a preparation method of an ultra-high-speed transmission data line of the present invention, which comprises the following steps:

[0027] (1) Prepare a number of signal transmission lines 1, and extrude at least one layer of low-dielectric material on the periphery of a conductor 11 made of a high-conductivity material as an insulating layer 12 to obtain a signal transmission line 1;

[0028] (2) Several signal transmission lines 1 are arranged in parallel as a control signal group 2, several signal transmission lines 1 are arranged in parallel as a high-frequency signal group 3, and several high-frequency signal groups 3 are arranged;

[0029] (3) Prepare several ground wires 4;

[0030] (4) Prepare a positioning mold, put a control signal group 2, several high-frequency signal groups 3 and several ground wires 4 side by side in the positioning mold for positioning, so that the control signal group 2, high-frequency signal group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com