Method of producing antifreeze fermented frozen waxy wheat dough containing recombinant lipase and pentosanase

A technology of pentosanase and lipase, which is applied in the field of food processing, can solve the problems of dough damage, bread specific volume reduction, gluten structure weakening, etc., and achieve the effects of prolonging shelf life, reducing interfacial tension, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

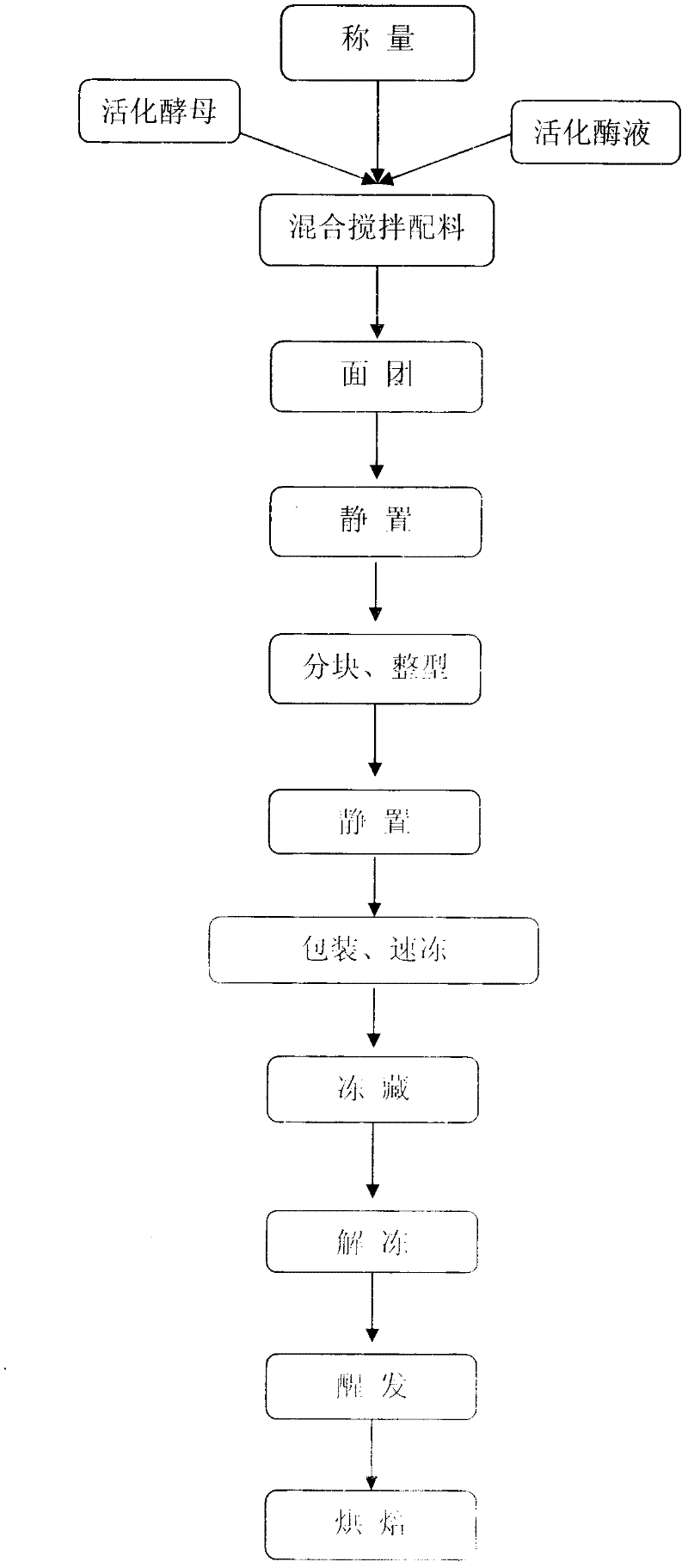

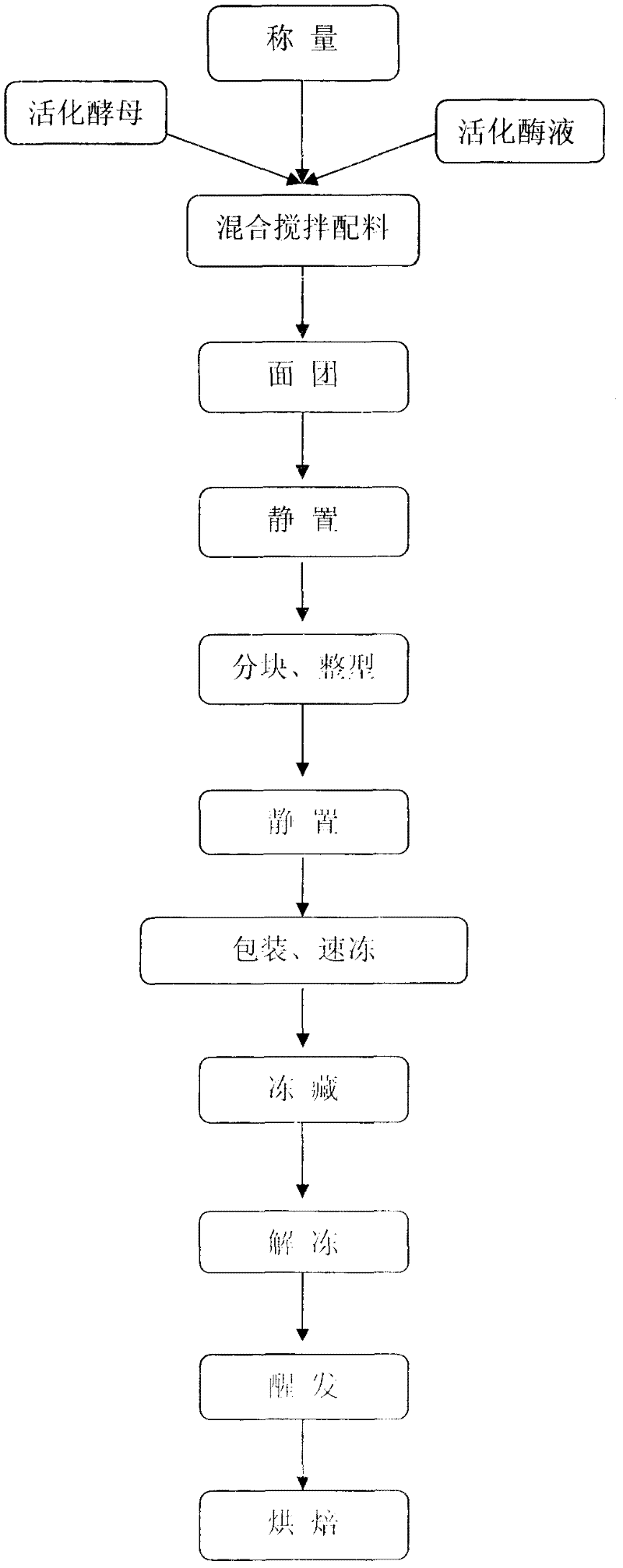

Method used

Image

Examples

Embodiment 1

[0022] In the embodiment of the present invention, 2.6% by weight of glutinous wheat flour, 50.1% by weight of high-gluten flour, 7.0% by weight of granulated sugar, 0.7% by weight of salt, 2.0% by weight of milk powder, 5.0% by weight of shortening, 1.2% by weight of yeast, and 0.0026% by weight of recombinant lipase %, pentosanase 0.0016% by weight, water 31.3958% by weight.

[0023] First take 0.0026% by weight of recombinant lipase and 0.0016% by weight of pentosanase and dissolve them in ice water (appropriate amount) to prepare a solution. The concentration of the solution is 3.5% by weight. Activation in a constant temperature incubator at 32°C for standby use; 1.2% by weight of active yeast was dissolved in ice water (appropriate amount) to prepare a solution with a concentration of 2.5% by weight, and placed in a constant temperature incubator at 28°C for activation. Mix glutinous wheat flour, high-gluten flour, granulated sugar, salt, milk powder, and shortening even...

Embodiment 2

[0025] In the embodiment of the present invention, 10.4% by weight of glutinous wheat flour, 41.0% by weight of high-gluten flour, 6.0% by weight of granulated sugar, 0.5% by weight of salt, 2.5% by weight of milk powder, 6.0% by weight of shortening, 1.0% by weight of yeast, and 0.0042% by weight of recombinant lipase %, pentosanase 0.0021% by weight, water 32.5937% by weight.

[0026] First take 0.0042% by weight of recombinant lipase and 0.0021% by weight of pentosanase and dissolve them in ice water (appropriate amount) to prepare a solution. 1.0% by weight of active yeast was dissolved in ice water (appropriate amount) to prepare a solution with a solution concentration of 2.5% by weight, and placed in a constant temperature incubator at 28°C for activation. Mix glutinous wheat flour, high-gluten flour, granulated sugar, salt, milk powder, and shortening evenly, add the remaining ice water, stir for 4 minutes at a slow speed, and stir for 4 minutes at a fast speed, then m...

Embodiment 3

[0028] In the embodiment of the present invention, 20.8% by weight of glutinous wheat flour, 31.2% by weight of high-gluten flour, 5.0% by weight of granulated sugar, 0.9% by weight of salt, 1.5% by weight of milk powder, 5.8% by weight of shortening, 0.8% by weight of yeast, and 0.0062% by weight of recombinant lipase %, pentosanase 0.0026% by weight, water 33.9912% by weight.

[0029]First take 0.0062% by weight of recombinant lipase and 0.0026% by weight of pentosanase and dissolve them in ice water (appropriate amount) to prepare a solution. The concentration of the solution is 4.5% by weight. Activate in a constant temperature incubator at °C for use; Dissolve 0.8% by weight of active yeast in ice water (appropriate amount) to prepare a solution with a concentration of 3.0% by weight, and place it in a constant temperature incubator at 30°C for activation for use. Mix glutinous wheat flour, high-gluten flour, granulated sugar, salt, milk powder, and shortening evenly, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com