Natural d-borneol extraction equipment

A technology of natural d-borneol and extraction equipment, which is applied in the preparation of hydroxyl compounds, organic compounds, organic chemistry, etc., can solve the problems of long distillation time, low heat energy utilization rate, large collection volume, etc., and reduce the collection volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

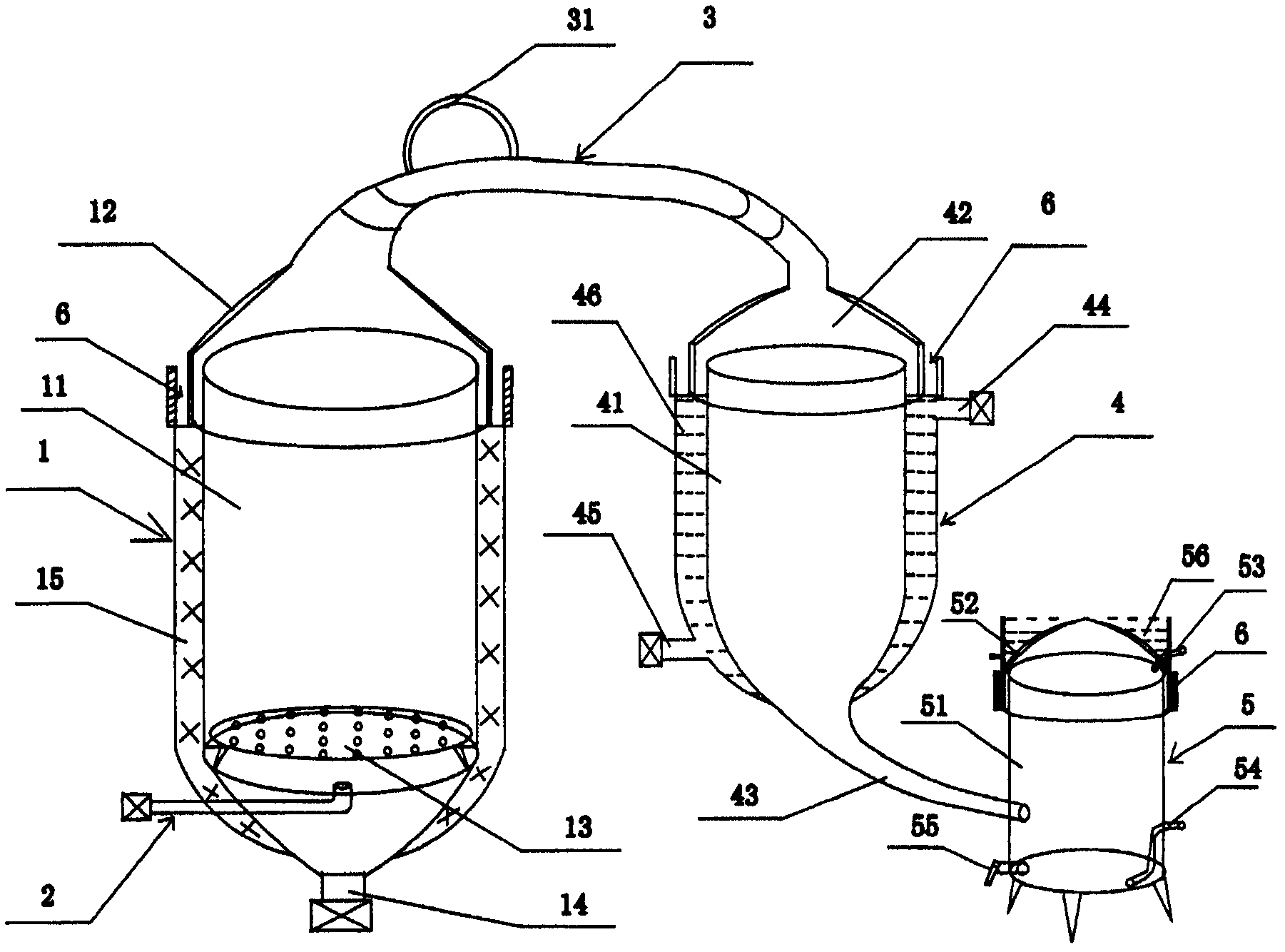

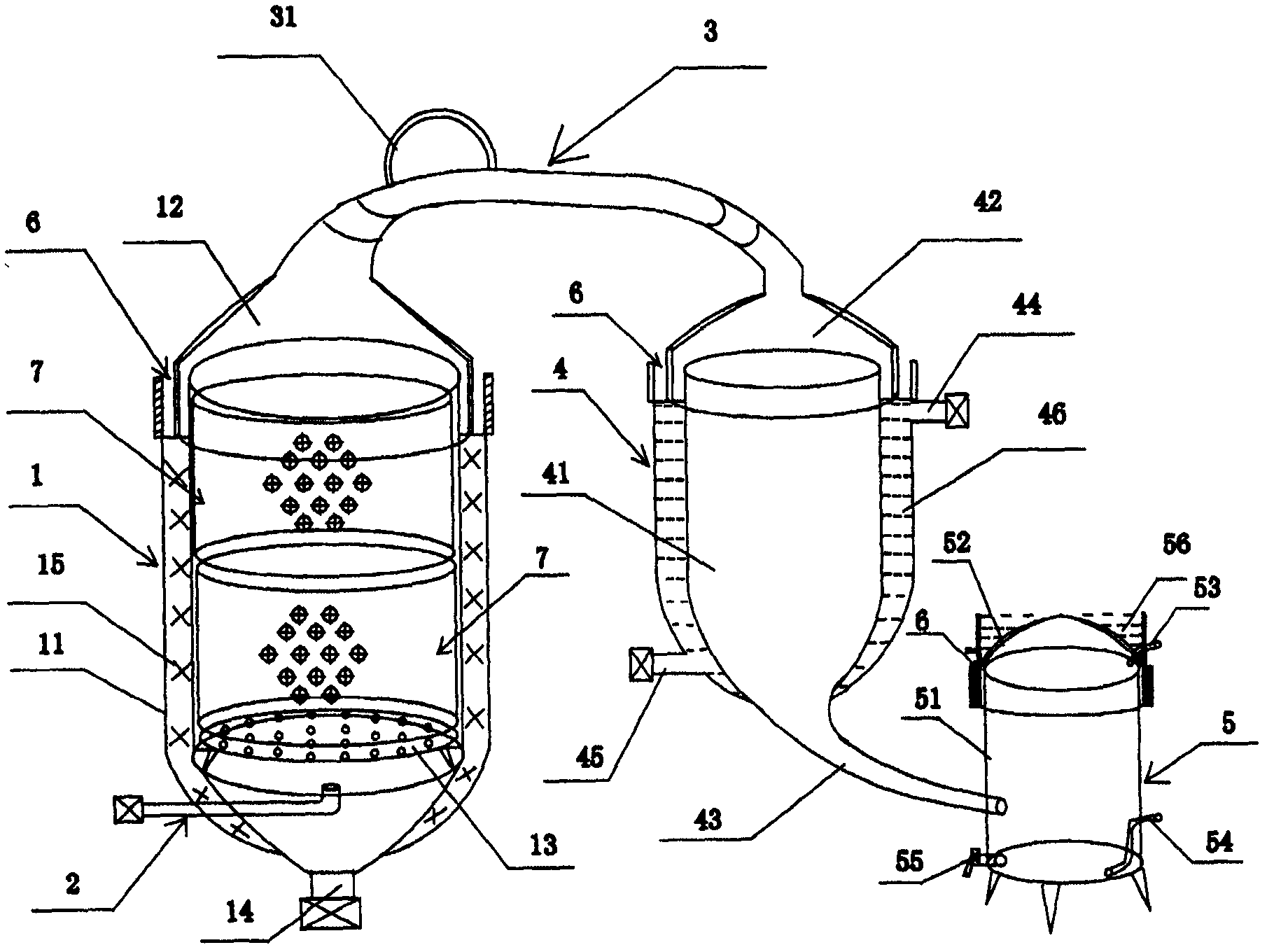

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

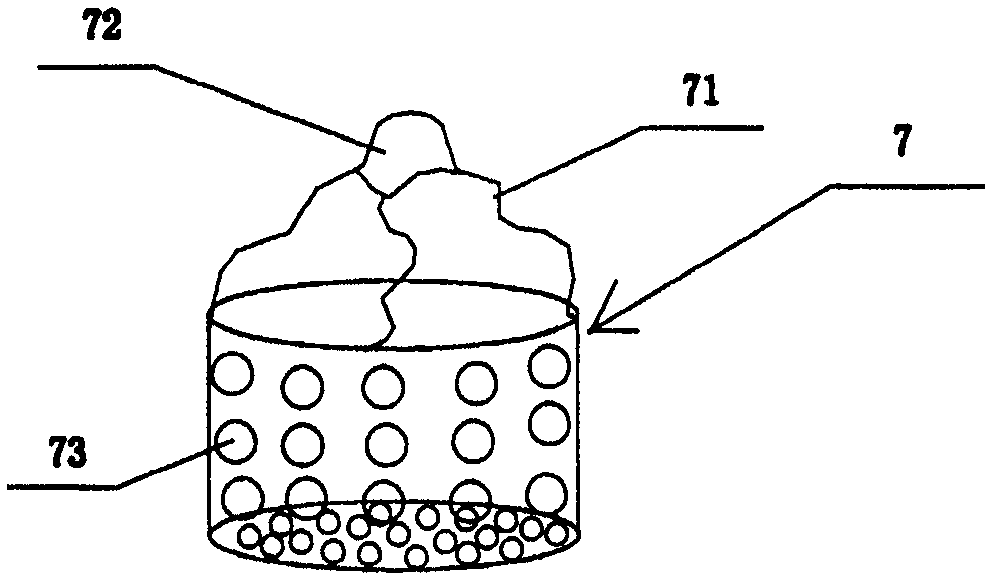

[0018] attached figure 1 and attached image 3 It clearly shows the composition structure and connection relationship of the present invention. The natural d-borneol extraction equipment of the present invention comprises a distillation tank 1, a steam conduit 2, a mixed steam conduit 3 and a condenser 4; The junction of the tank body 11 and the tank cover 12 is provided with a sealing structure that can easily open the upper cover, a thermal insulation layer 15 is provided outside the tank body 11 of the distillation tank 1, and an observation window is also installed on the tank cover 12 of the distillation tank 1; steam; One end of the conduit 2 is connected to the bottom of the distillation tank 1 and communicated with the interior of the distillation tank 1; the condenser 4 includes a main body 41 and a cover body 42, and a sealing struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com