Heat recovery steam generator flue gas denitration apparatus

A waste heat boiler and flue gas technology, which is applied in the fields of greenhouse gas capture, climate sustainability, and separation of dispersed particles, can solve problems such as NOx emissions, achieve uniform molar ratio, reduce energy consumption, reduce investment and occupy an area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following non-limiting examples illustrate the invention.

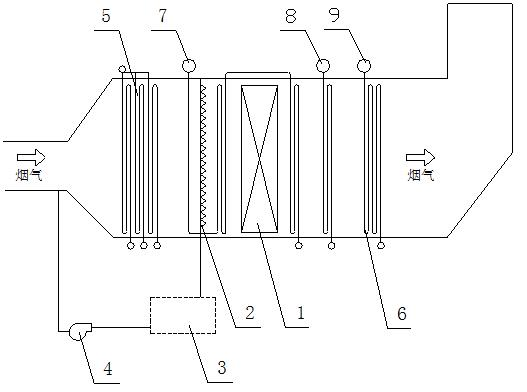

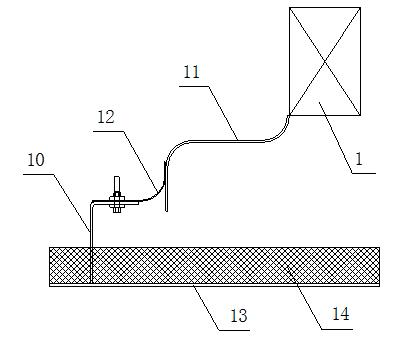

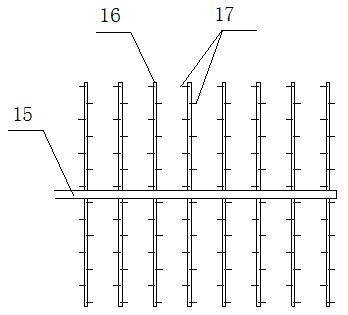

[0022] Such as Figure 1 to Figure 3 As shown, a waste heat boiler flue gas denitration device includes an evaporator 6 arranged in the waste heat boiler, which has multiple heating surfaces along the flue gas flow channel, and the temperature gradually decreases along the flue gas direction, and also includes a denitrification reactor 1 , a reducing agent injection system 2, and a preparation system 3 for providing reducing agent for the reducing agent injection system 2, a catalyst is provided in the denitration reactor 1, and the denitration reactor 1 is arranged between two adjacent heating surfaces of the evaporator 6, The temperature between the two heating surfaces is the optimal reaction temperature of the denitrification catalyst. The reducing agent injection system 2 sprays the reducing agent uniformly on the section of the flue gas flow channel. There are several stages of heating surfaces betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com