Bio-based internal olefin sulfonate surfactant and preparation method thereof

A technology of internal olefin sulfonate and surfactant, which is applied in the field of bio-based internal olefin sulfonate surfactant and its preparation, can solve the problems of high cost and restrictions on the popularization of composite flooding technology, and achieve low production cost and improved Effect of oil recovery and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

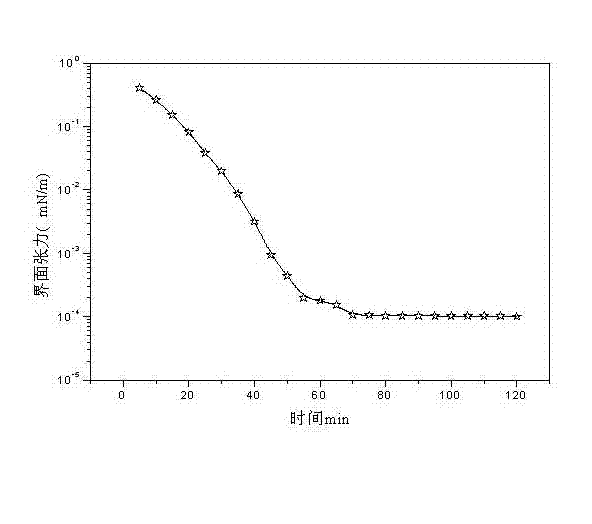

Examples

Embodiment 1

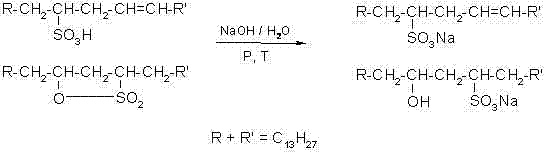

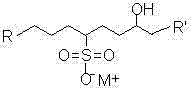

[0038] In a three-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 56.5g of oleic acid and 51.2g of anhydrous methanol, add 1.0g of concentrated sulfuric acid into the three-necked flask, and heat to 100°C for 2 hours under stirring. After the reaction was completed, the product was washed with water to pH=7, dried with anhydrous sodium sulfate, and excess methanol was distilled off under reduced pressure to obtain methyl oleate as a light yellow oily transparent liquid.

[0039] Refined 3.9g tungsten hexachloride (WCl 6 ) into a three-necked flask, filled with nitrogen, and added 200ml of dry benzene; at a temperature of 28°C, slowly added 1.9g of tetramethyltin (SnMe 4 ), after stirring for 10 minutes, dissolve 44.4g of methyl oleate in 80ml of benzene and add it into the three-necked flask, continue stirring for 10 minutes, raise the temperature to 70°C, and react for 20 hours. After the reaction is over, add 100ml of sodium hydroxi...

Embodiment 2

[0047] In a three-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 56.5g of oleic acid and 73.6g of absolute ethanol, add 1.0g of concentrated sulfuric acid into the three-necked flask, and heat to 110°C for 2 hours under stirring , After the reaction was completed, the product was washed with water to pH = 7, dried with anhydrous sodium sulfate, and excess methanol was distilled off under reduced pressure to obtain ethyl oleate as a light yellow oily transparent liquid.

[0048] Refined 3.9g tungsten hexachloride (WCl 6 ) into a three-necked flask, filled with nitrogen, and added 200ml of dry benzene; at a temperature of 28°C, slowly added 1.9g of tetramethyltin (SnMe 4 ), after stirring for 10 minutes, dissolve 46.5g of ethyl oleate in 80ml of benzene and add it into the three-necked flask, continue stirring for 10 minutes, raise the temperature to 70°C, and react for 20 hours. After the reaction is over, add 100ml of sodium hydroxid...

Embodiment 3

[0056] In a three-necked flask equipped with an electric stirrer, a reflux condenser and a thermometer, add 56.5g of oleic acid and 51.2g of anhydrous methanol, add 1.0g of concentrated sulfuric acid into the three-necked flask, and heat to 100°C for 2 hours under stirring. After the reaction was completed, the product was washed with water to pH=7, dried with anhydrous sodium sulfate, and excess methanol was distilled off under reduced pressure to obtain methyl oleate as a light yellow oily transparent liquid.

[0057] Refined 2g tungsten hexachloride (WCl 6 ) into a three-necked flask, filled with nitrogen, and added 150ml of dry benzene; at a temperature of 20°C, slowly added 1.0g of tetramethyltin (SnMe 4 ), after stirring for 20 minutes, dissolve 40g of methyl oleate in 50ml of benzene and add it into the three-necked flask, continue to stir for 20 minutes, raise the temperature to 80°C, and react for 10 hours. After the reaction, add 80ml of sodium hydroxide solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com