Method for producing hierarchically structured porous coordination polymer absorbent material

A technology of coordination polymers and adsorption materials, applied in chemical instruments and methods, adsorption water/sewage treatment, textile industry wastewater treatment, etc. The effect of high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 (raw material corresponding to embodiment 1 in the comparison table and the proportioning value thereof by weight) is carried out in three steps:

[0025] (1) Dissolve 5 parts by weight of 5-hydroxyisophthalic acid and 2.2 parts by weight of sodium hydroxide in 250 parts by weight of water at 75°C;

[0026] (2) Dissolving 2.4 parts by weight of aluminum sulfate in 50 parts by weight of normal temperature water;

[0027] (3) Slowly add the solution obtained in step (2) to the solution obtained in step (1), stir while adding, continue to react for 2 hours after the addition, filter with suction, wash with water, and dry at 160°C to obtain Hierarchical structure of pore coordination polymer adsorption materials.

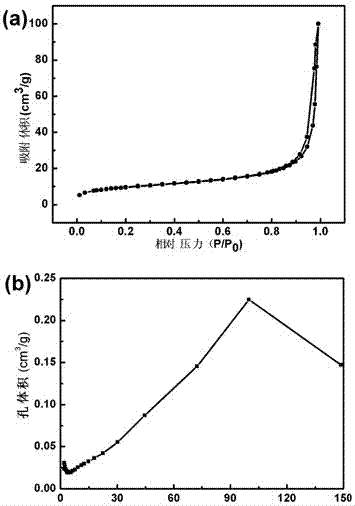

[0028] For the rest of Examples 2-7, respectively compare the raw materials and their weight ratios of the corresponding examples in the above table, and use the same method as Example 1 to produce a mixture of mesopores and macropores in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com