Tubular target bonding method

A bonding method and target material technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of uneven thickness of bonding layer or welding layer, adverse effects of sputtering process, difficult target tube and liner For medium problems, the effect of improving welding quality, saving welding materials and improving performance can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

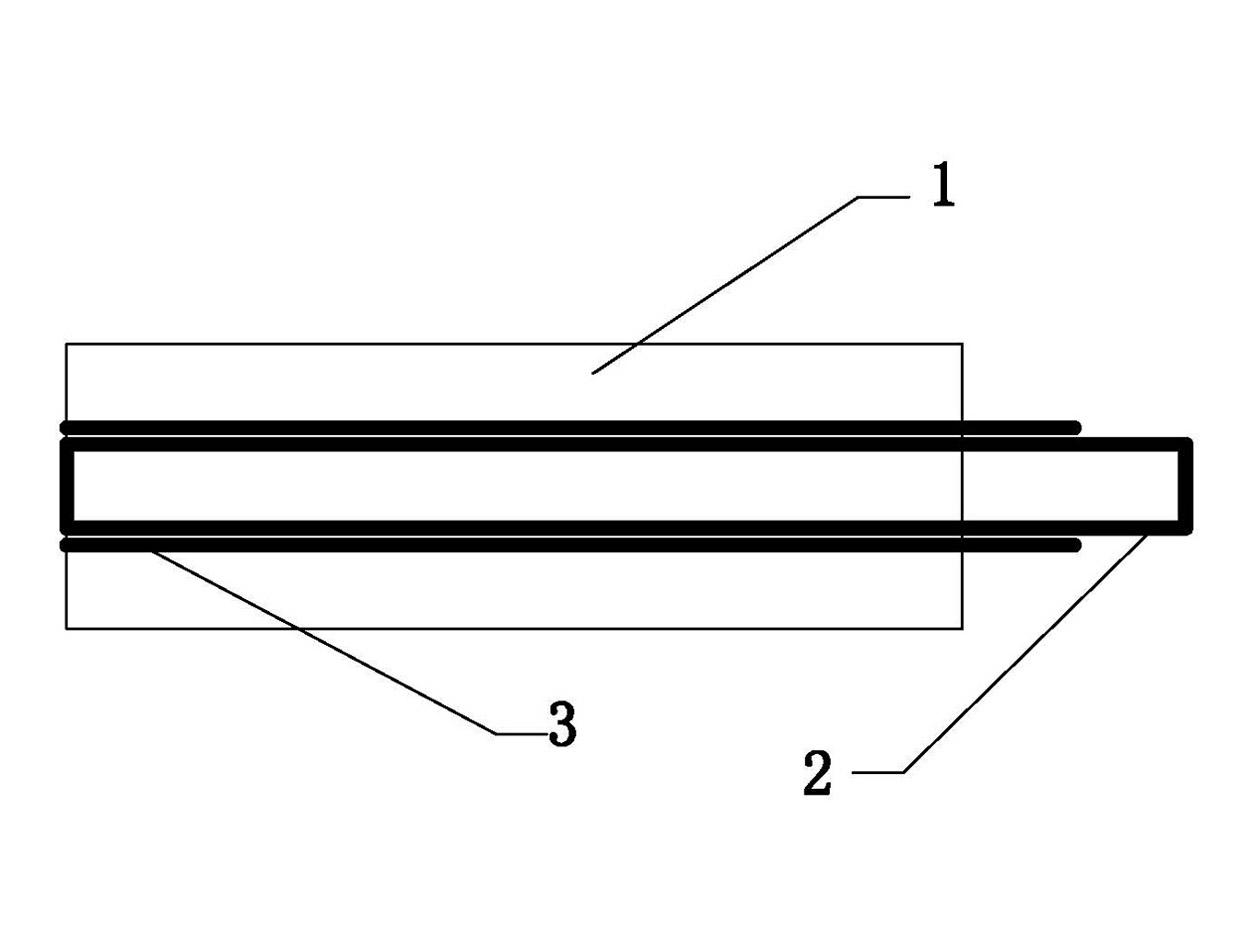

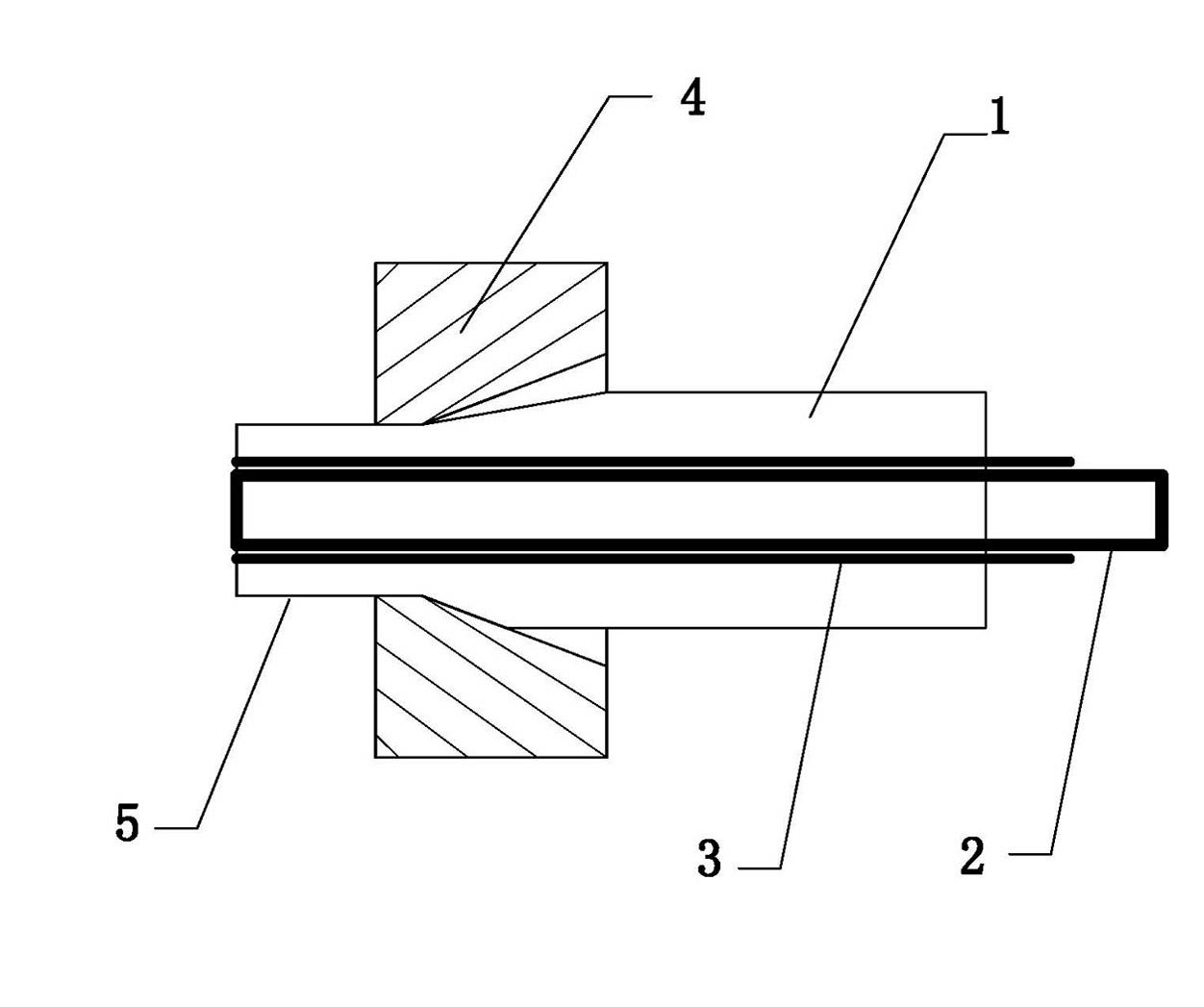

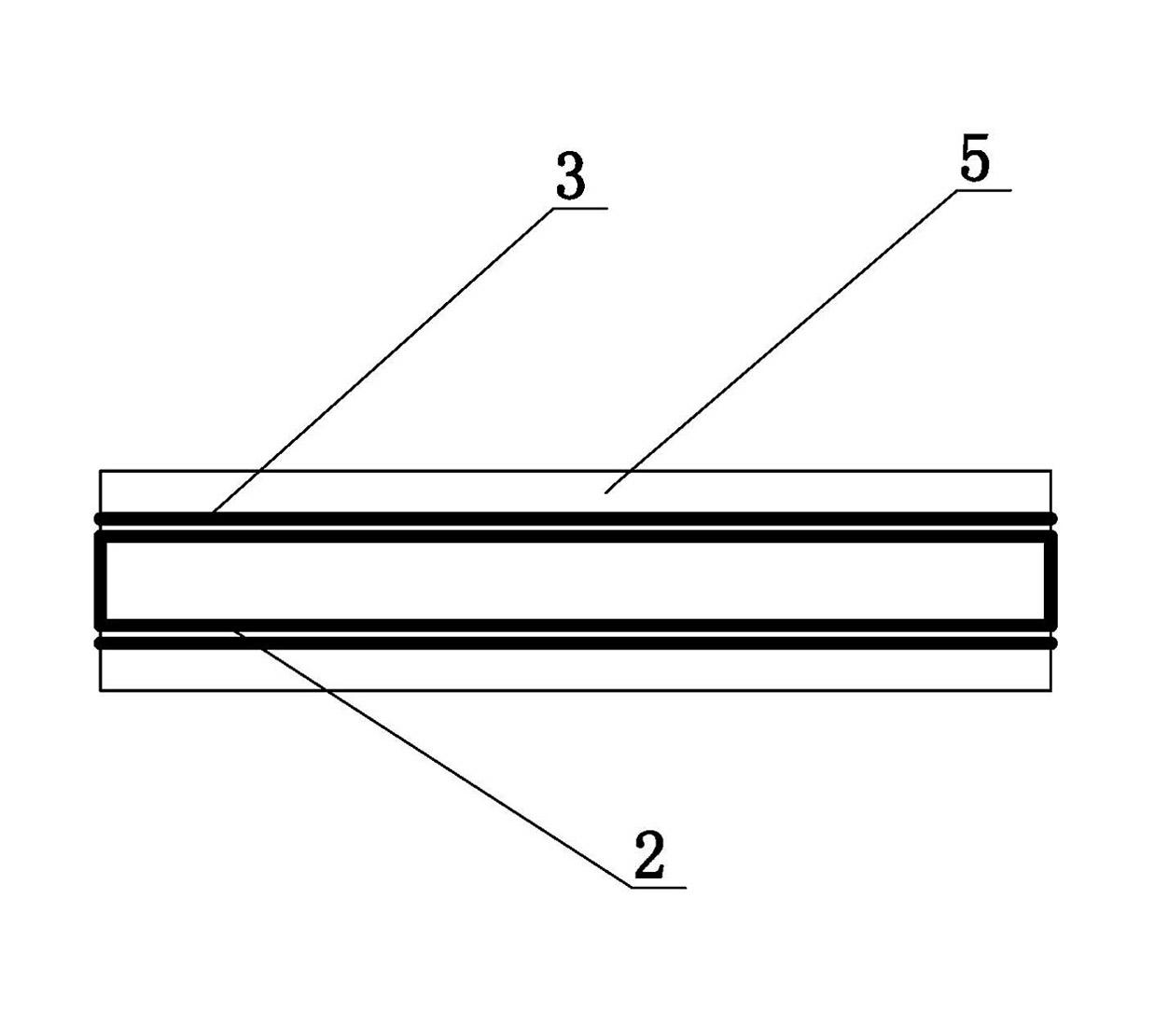

[0027] Embodiment 1: as figure 1 , 2 , Shown in 3, a kind of bonding method of tubular target material, the steps of this method are as follows:

[0028] Step 1: First process the target tube blank whose inner diameter and thickness are larger than the final requirement, and whose length is shorter than the final requirement; select a metal liner whose inner diameter and outer diameter are exactly the same as the final requirement, but whose length is longer than the final requirement;

[0029] Step 2: Grinding, sandblasting, cleaning and coating the surface of the target tube blank and metal liner to be bonded;

[0030] Step 3: Evenly coat a layer of low-melting point solder on the outer surface of the treated metal liner, and the thickness of the low-melting point solder coating should not be less than the designed solder layer thickness;

[0031] Step 4: Set the metal liner coated with low melting point solder inside the target tube blank;

[0032] Step 5: After the meta...

Embodiment 2

[0039] Embodiment 2: as figure 1 , 2 , Shown in 3, a kind of bonding method of tubular target material, the steps of this method are as follows:

[0040] The first step: process the target tube blank whose inner diameter and thickness are larger than the final requirement, and whose length is smaller than the final requirement.

[0041] final requirements; select a metal liner whose inner diameter and outer diameter are exactly the same as the final requirements, but whose length is longer than the final requirements;

[0042] Step 2: Grinding, sandblasting, cleaning and coating the surface of the target tube blank and metal liner to be bonded;

[0043] Step 3: Evenly coat a layer of low-melting point solder on the outer surface of the treated metal liner, and the thickness of the low-melting point solder coating should not be less than the designed solder layer thickness;

[0044] Step 4: Set the metal liner coated with low melting point solder inside the target tube blank; ...

Embodiment 3

[0052] Embodiment 3: as figure 1 , 2 , Shown in 3, a kind of bonding method of tubular target material, the steps of this method are as follows:

[0053] The first step: process the target tube blank whose inner diameter and thickness are larger than the final requirement, and whose length is smaller than the final requirement.

[0054] final requirements; select a metal liner whose inner diameter and outer diameter are exactly the same as the final requirements, but whose length is longer than the final requirements;

[0055] Step 2: Grinding, sandblasting, cleaning and coating the surface of the target tube blank and metal liner to be bonded;

[0056] Step 3: Evenly coat a layer of low-melting point solder on the outer surface of the treated metal liner, and the thickness of the low-melting point solder coating should not be less than the designed solder layer thickness;

[0057] Step 4: Set the metal liner coated with low melting point solder inside the target tube blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com