Wood drying process and wood drying system

A wood drying and wood technology, which is applied in the wood drying process of mahogany products and its system field, can solve the problems of unqualified drying of wooden furniture materials, poor product quality stability, deformation paint adhesion, etc., to reduce deformation and balance moisture content , Reduce the effect of deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

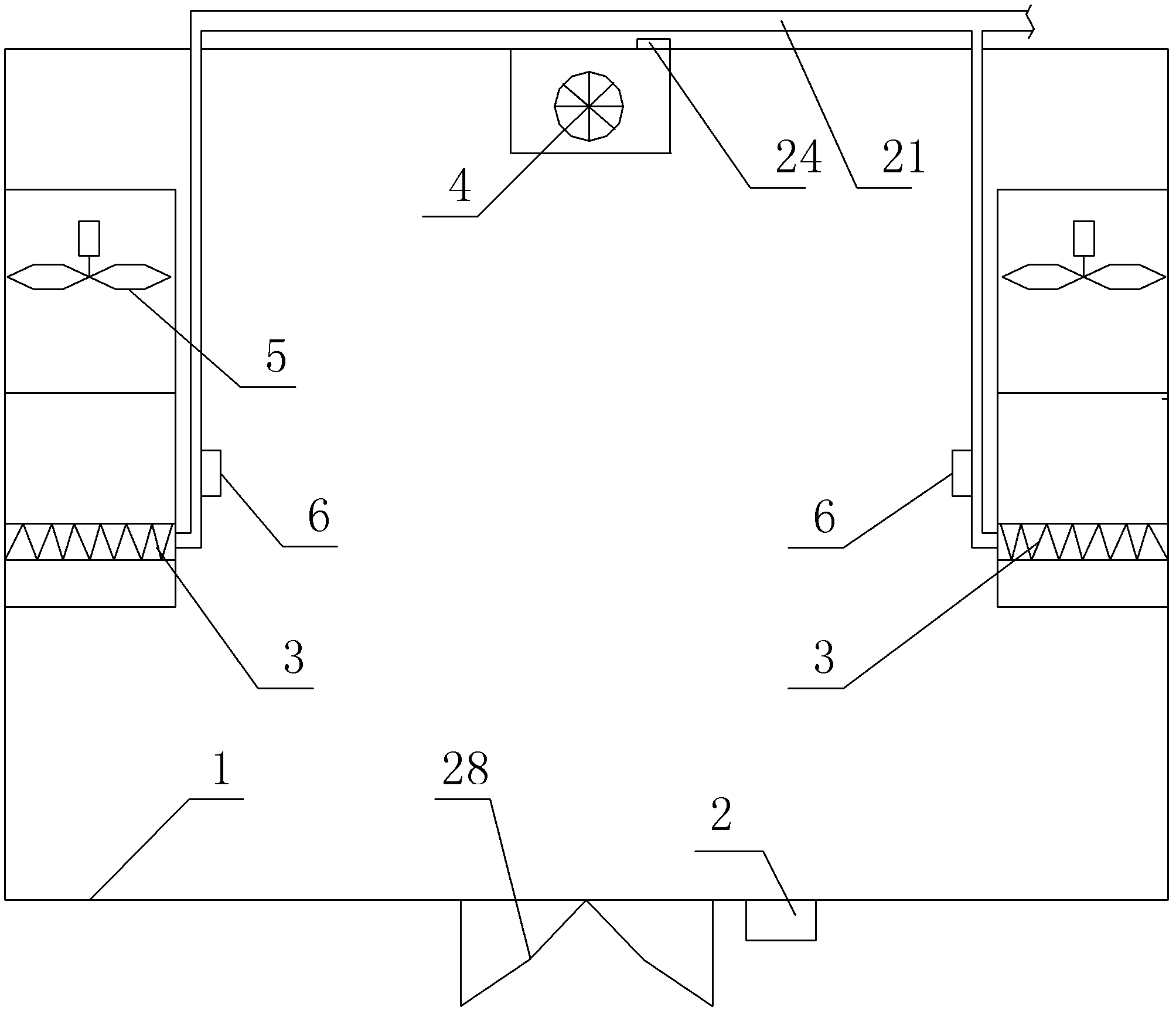

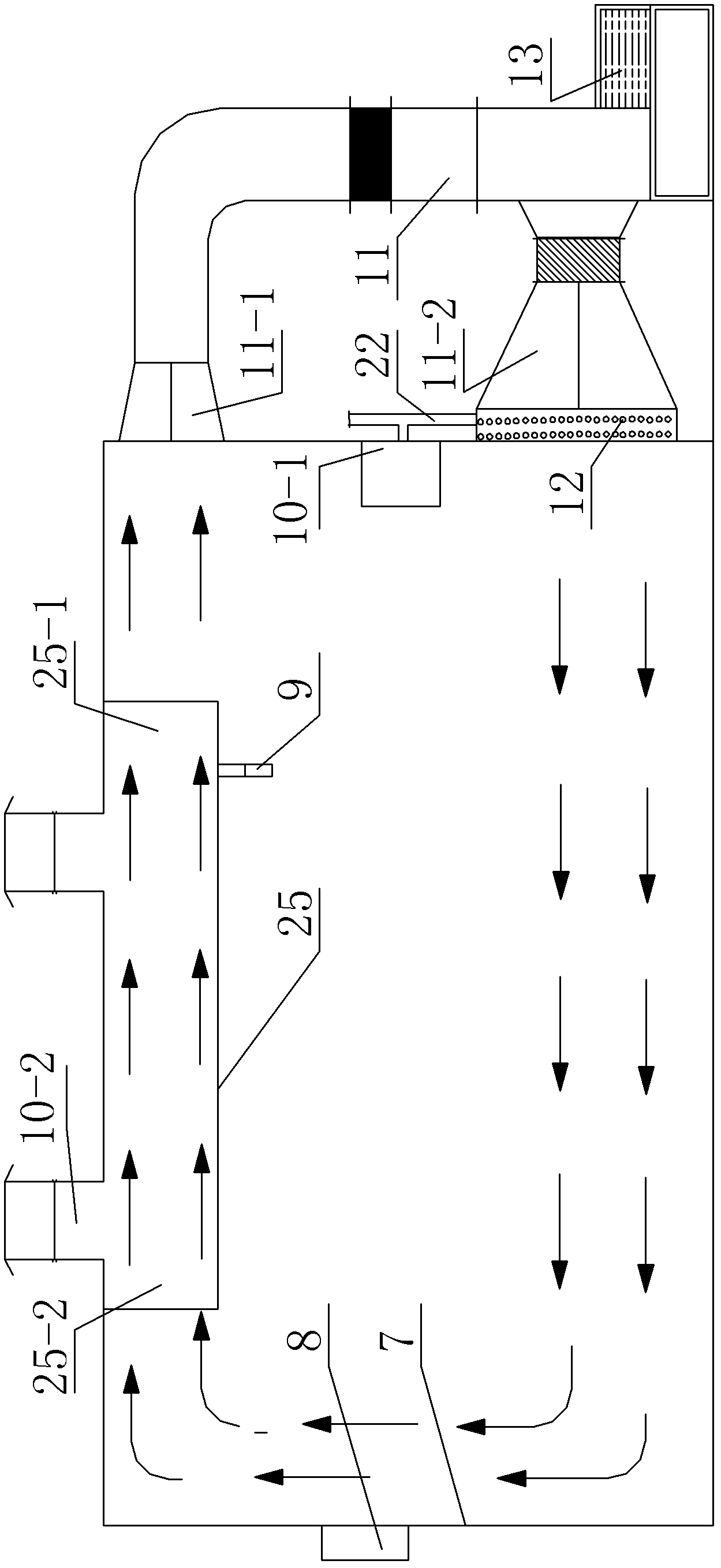

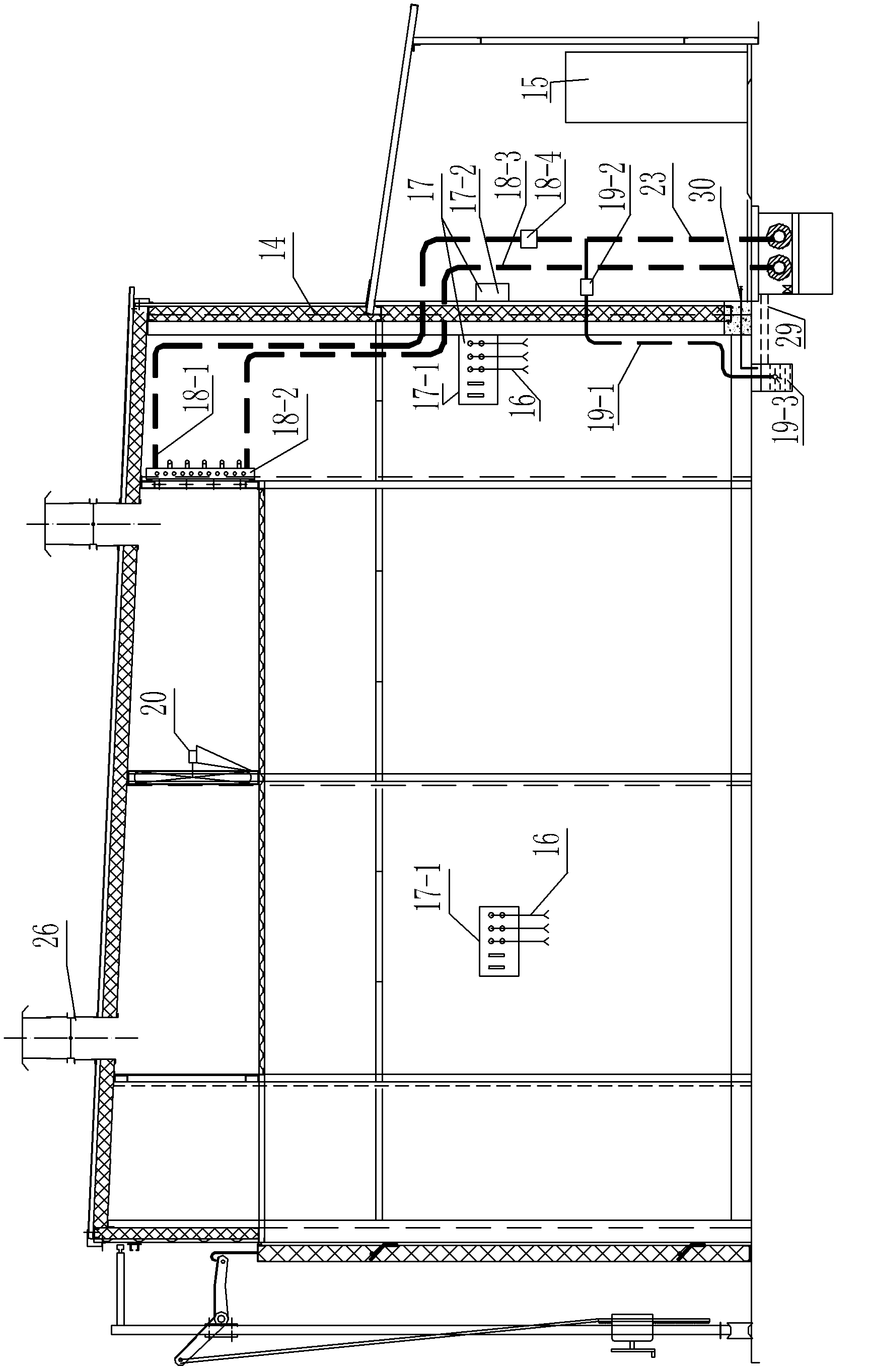

[0092] After the wood is dried as a whole, it is subjected to health-care drying treatment; the health-care drying treatment is to place the wood in a health-care drying treatment room 1 with the ambient temperature controlled at 20° C. and the ambient humidity controlled at 25% for 4 days.

Embodiment 2

[0094] After the wood is dried as a whole, the health-preserving and drying treatment is carried out; the health-preserving and drying treatment is to place the wood in the health-preserving and drying treatment room 1 with the ambient temperature controlled at 30° C. and the ambient humidity controlled at 35% for 5 days.

Embodiment 3

[0096] After the wood is dried as a whole, the health-preserving and drying treatment is carried out; the health-preserving and drying treatment is to place the wood in a health-preserving and drying treatment room 1 with the ambient temperature controlled at 25° C. and the ambient humidity controlled at 30% for 4.5 days.

[0097] Experiment 1:

[0098] Select wood of the same material and specification and divide it into experimental group 1, experimental group 2, experimental group 3 and control group 1.

[0099]The wood of the experimental group 1, the experimental group 2, the experimental group 3 and the control group 1 were subjected to the same whole wood drying treatment at the same time.

[0100] After the overall drying of the wood, the experimental group 1 was processed according to the wood drying process described in Example 1; the experimental group 2 was processed according to the wood drying process described in Example 2; the experimental group 3 was processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com