Method and device for treating chlorosilane liquid produced in polysilicon production

A processing device and processing method technology, applied in the directions of silicon oxide, silicon dioxide, chlorine/hydrogen chloride, etc., can solve problems such as safety and environmental hazards, and achieve the effects of long service life and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

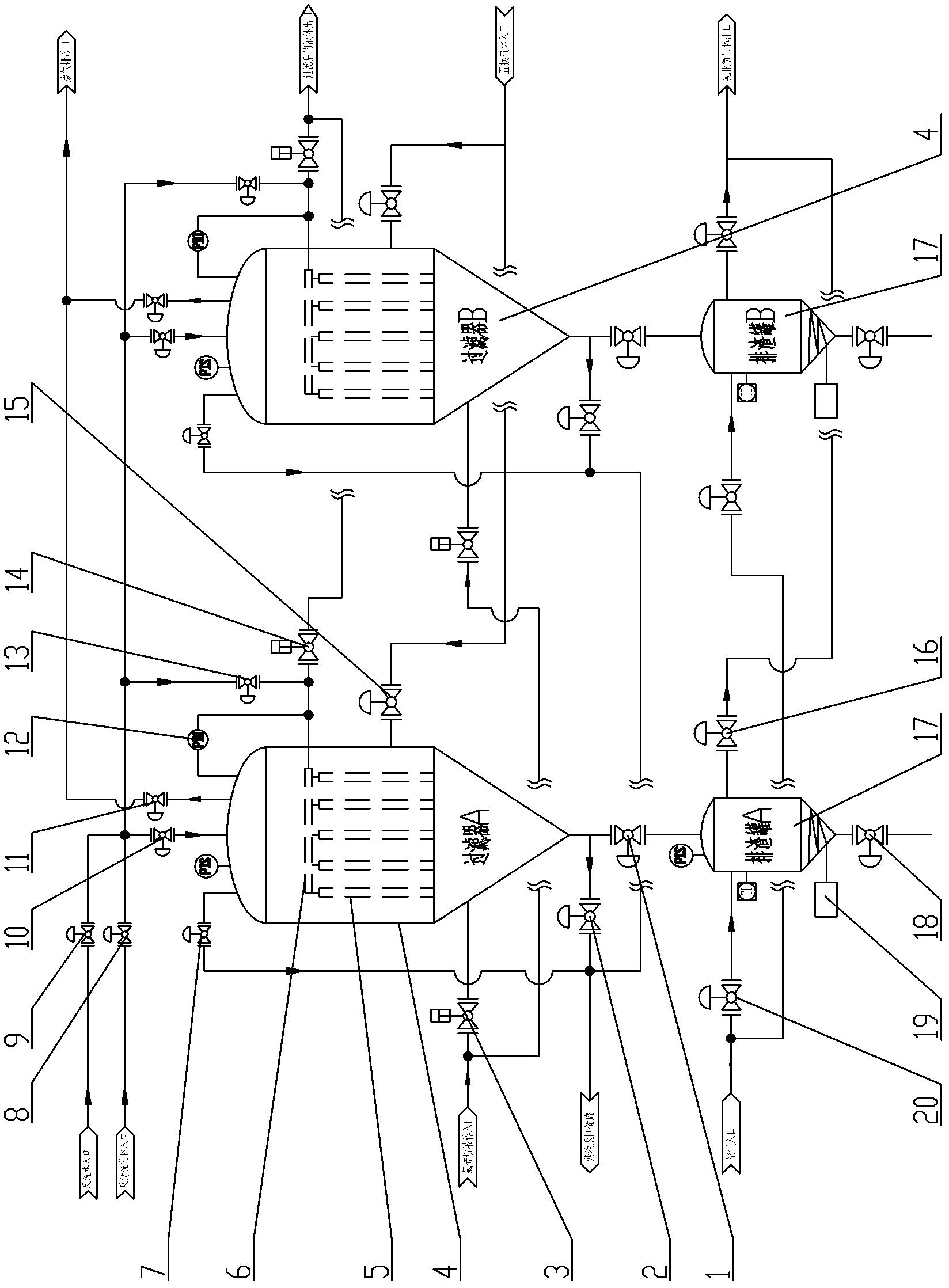

[0024] figure 2 Among them, including bottom slag discharge valve 1, residual liquid return valve 2, liquid inlet valve 3, pipe filter 4, filter element 5, liquid collection pipe 6, overflow valve 7, air supply valve 8, water supply valve 9, the second One backwash valve 10, exhaust valve 11, differential pressure transmitter 12, second backwash valve 13, liquid outlet valve 14, safety gas replacement valve 15, hydrogen chloride gas outlet valve 16, slag discharge tank 17, silicon dioxide Drain valve 18, auxiliary heating system 19, air inlet valve 20, etc.

[0025] The present invention uses a tubular filter to filter the chlorosilane liquid. The structure of the tubular filter adopts the Chinese utility model patent with the patent number 200820057362.4 and the patent name "a catalyst recovery filter".

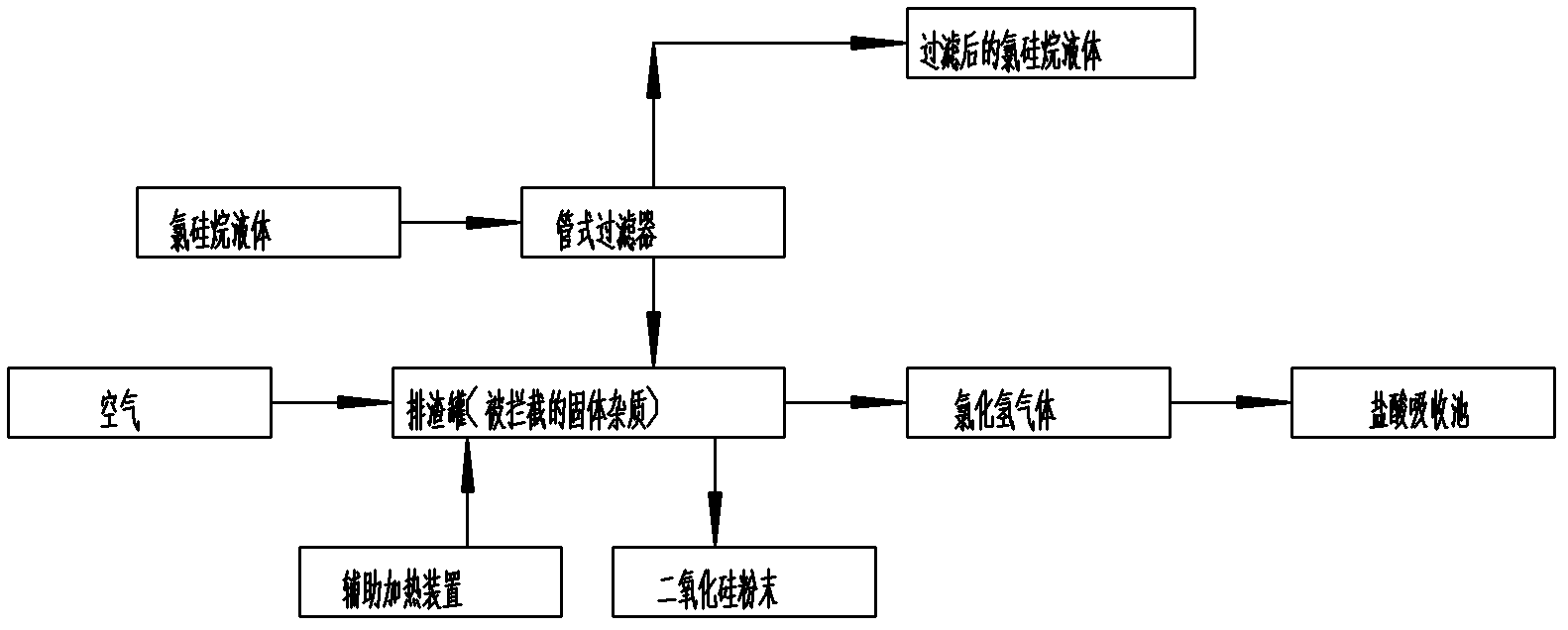

[0026] Such as figure 1 Shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com