Integral-type heteroatom replacing hierarchical porous molecular sieve and synthesis method thereof

A technology of heteroatom and molecular sieve, which is applied in the field of monolithic heteroatom-substituted multi-stage porous molecular sieve and its one-step synthesis, achieving the effects of low temperature, short crystallization time and reduced water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The sol (2.8 wt.% Al 2 o 3 ), 2g of water and 4g of tetrapropylammonium hydroxide mixed at 25 o After C was stirred for 3 hours, 3.5ml of 6% NaOH solution was added to it, and then 0.06g of Fe(NO 3 ) 3 .9H 2 O get the gel mixture, move the gel mixture into the stainless steel synthesis kettle and seal it at 155 o C crystallization for 24 hours, the product of monolithic molecular sieve was washed, dried and 550 o After C was calcined for 6 hours, the heteroatom substituted hierarchical porous Fe-ZSM-5 molecular sieve was obtained. Its chemical formula is Na + 0..073 [(Fe 0.006 al 0.067 Si 0.927 )O 2 ].60H 2 O.

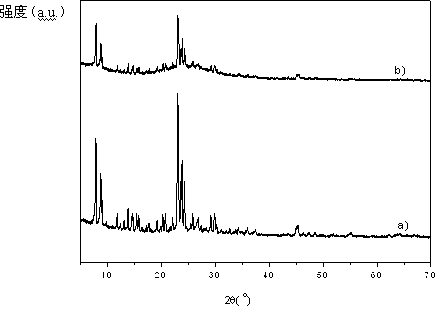

[0018] figure 1 a is the XRD characterization result of the product, by figure 1 a It can be seen that the product has a typical MFI ZSM-5 molecular sieve structure, and the sample has a high degree of crystallinity, indicating that the product has good hydrothermal stability.

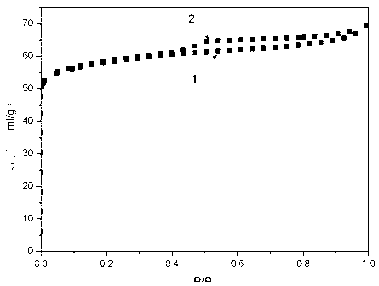

[0019] figure 2 and image 3 Respectively, the low-temperature ni...

Embodiment 2

[0023] The sol (2.8 wt.% Al 2 o 3 ), 2g of water and 4g of tetrapropylammonium hydroxide mixed at 25 o After C was stirred for 3 hours, 3.5ml of 6% NaOH solution was added to it, and then 0.06g of Fe(NO 3 ) 3 .9H 2 O get the gel mixture, move the gel mixture into the stainless steel synthesis kettle and seal it at 170 o C crystallized for 24 hours to obtain the product of the monolithic molecular sieve after washing, drying and 550 o After C is calcined for 6 hours, the whole body of Fe-ZSM-5 molecular sieve with heteroatoms and hierarchical pores can be obtained. Its chemical formula is Na + 0..073 [(Fe 0.006 al 0.067 Si 0.927 )O 2 ].60H 2 O.

Embodiment 3

[0025] The sol (2.8 wt.% Al2 o 3 ), 2g of water and 4g of tetrapropylammonium hydroxide mixed at 25 o After C was stirred for 3 hours, 3.5ml of 6% NaOH solution was added to it, and then 0.12g of Fe(NO 3 ) 3 .9H 2 O get the gel mixture, move the gel mixture into the stainless steel synthesis kettle and seal it at 170 o C crystallized for 24 hours to obtain the product of the monolithic molecular sieve after washing, drying and 550 o After C was calcined for 6 hours, the heteroatom substituted hierarchical porous Fe-ZSM-5 molecular sieve was obtained. Its chemical formula is Na + 0.067 [(Fe 0.023 al 0.044 Si 0.933 )O 2 ].60H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com