Preparation method for activated alumina with large pore volume and high specific surface area

A high specific surface area, activated alumina technology, applied in the direction of alumina/hydroxide preparation, chemical instruments and methods, catalyst supports, etc., can solve the complex process and the difficulty of activated alumina to simultaneously exert large pore volume and high specific surface area , high production costs, etc., to achieve the effect of simple process, large pore size and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

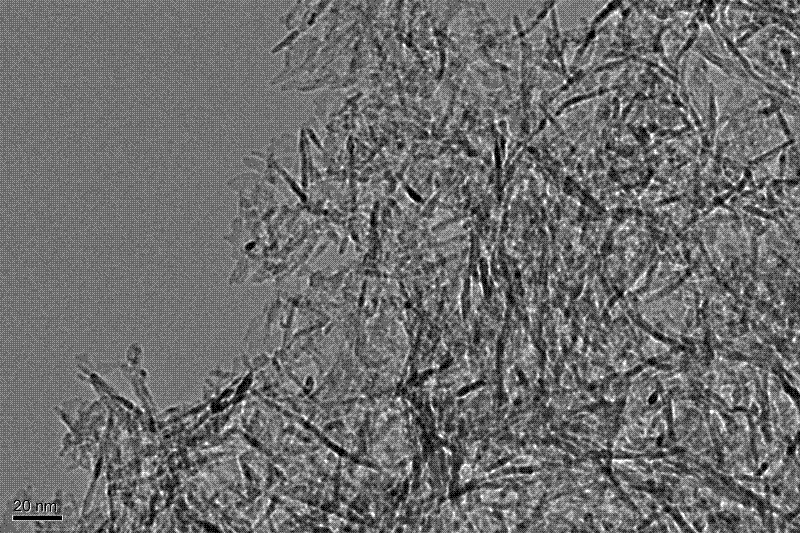

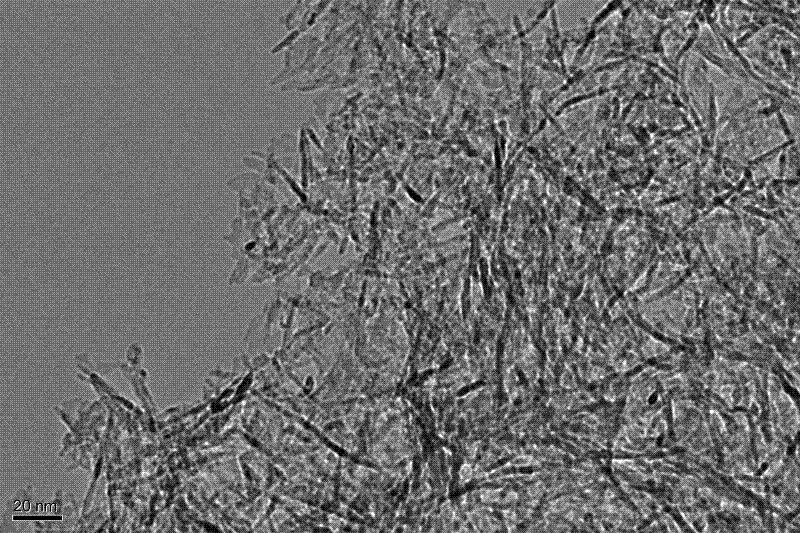

Image

Examples

Embodiment 1

[0014] Embodiment 1; Get 100ml, the nitric acid solution of 1mol / L is placed in the beaker, setting water-bath reaction temperature is 30 ℃ and carries out magnetic stirring, sodium aluminate solution (αk=1.45) is slowly dripped in the above solution, until The pH of the solution reached 10. Set the aging temperature to 60°C and carry out vigorous stirring aging, and the aging time is 2h. After aging, vacuum suction filtration was used for solid-liquid separation and ultrasonic washing several times, and the obtained filter cake was transferred to a distillation flask, and n-butanol was added at a ratio of solid-liquid volume ratio = 1:5 for co-distillation. The obtained activated alumina precursor was put into a muffle furnace and roasted at 500°C for 4 hours to obtain activated alumina with large pore volume and high specific surface area.

Embodiment 2

[0015] Embodiment 2: Get 100ml, the nitric acid solution of 1mol / L is placed in the beaker, setting water-bath reaction temperature is 30 ℃ and carries out magnetic stirring, sodium aluminate solution (αk=1.40) is slowly dripped in the above solution, until The pH of the solution reached 9. Set the aging temperature to 70°C and carry out vigorous stirring aging, and the aging time is 4h. After aging, vacuum suction filtration was used for solid-liquid separation and ultrasonic washing several times. The obtained filter cake was transferred to a distillation flask, and n-butanol was added at a ratio of solid-liquid volume ratio = 1:4 for co-distillation. The obtained activated alumina precursor was put into a muffle furnace and roasted at 500°C for 4 hours to obtain activated alumina with large pore volume and high specific surface area.

Embodiment 3

[0016] Embodiment 3; Get 100ml, the nitric acid solution of 2mol / L is placed in the beaker, setting water bath reaction temperature is 20 ℃ and carries out magnetic stirring, sodium aluminate solution (αk=1.35) is slowly dripped in the above solution, until The pH of the solution reached 9. Set the aging temperature to 80°C and carry out vigorous stirring aging, and the aging time is 5h. After aging, vacuum suction filtration was used for solid-liquid separation and ultrasonic washing several times, and the obtained filter cake was transferred to a distillation flask, and n-butanol was added at a ratio of solid-liquid volume ratio = 1:5 for co-distillation. The obtained activated alumina precursor was put into a muffle furnace and roasted at 500°C for 4 hours to obtain activated alumina with large pore volume and high specific surface area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com