High-acid-dissolution-rate core material glass component for microchannel plate

A technology of micro-channel plate and core glass, which is applied in the field of high acid dissolution rate core glass components, can solve the problems of single acid dissolution glass system, and achieve the effect of high acid dissolution rate and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

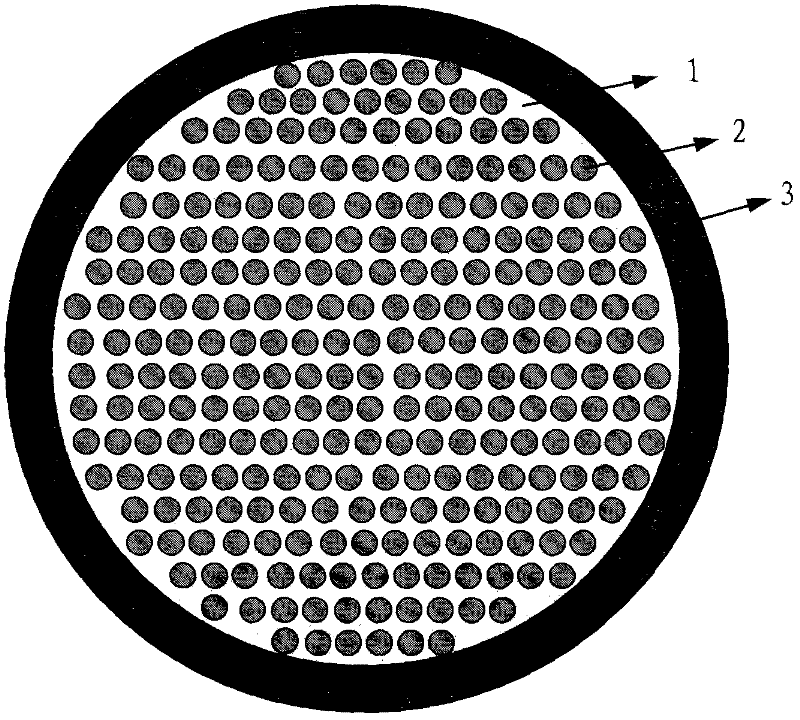

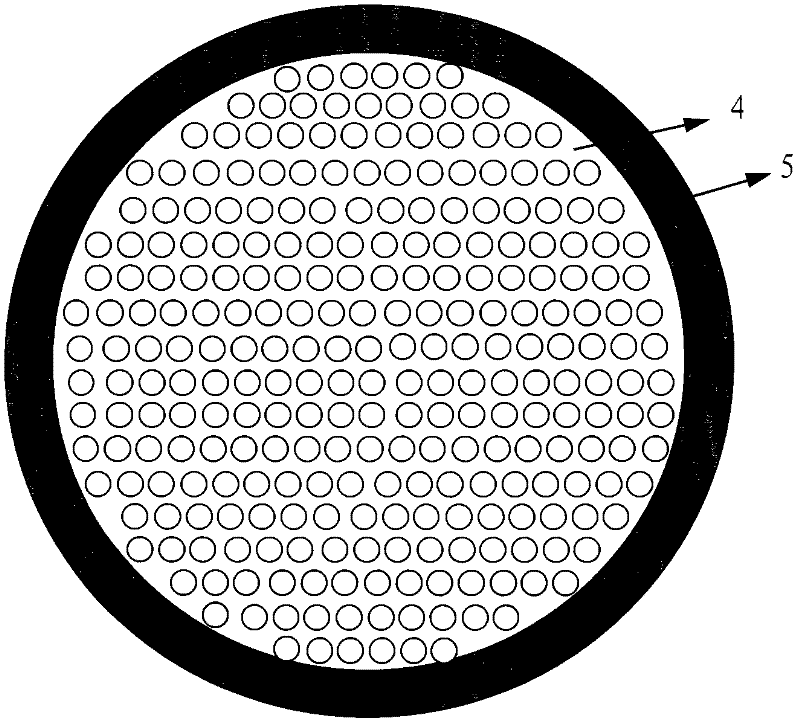

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

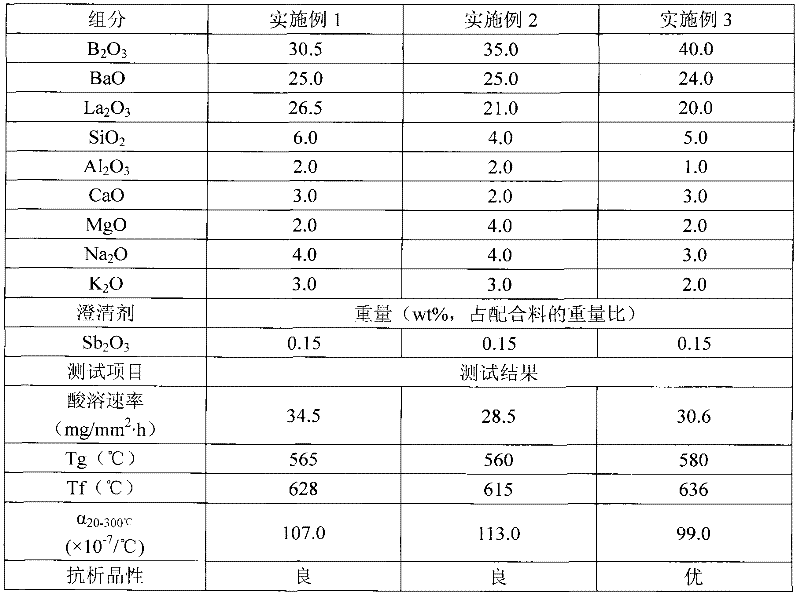

[0022] The present invention relates to high acid dissolution rate microchannel plate core material glass components comprising B 2 o 3 , BaO, La 2 o 3 , SiO 2 、Al 2 o 3 , MgO, CaO, Na 2 O, K 2 O, clarifying agent Sb 2 o 3 .

[0023] Among them: B 2 o 3 It is a glass former oxide, the basic skeleton of the glass structure, and the main component of acid-soluble glass. Its content exceeds 40wt%, and the glass contains a large amount of [BO 3 ] Trihedral, while reducing the chemical stability of the glass, it also reduces the glass viscosity and thermal expansion coefficient, and deteriorates the incompatibility with the microchannel skin glass; BaO is the outer body oxide of the glass, which is to improve the hyaluronic acid The main oxide component of the dissolution rate is also the flux of the glass. Replacing CaO with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com