Preparation method of nano-grade silver antibiotic fabric

A nano-silver antibacterial and nano-silver technology, which is applied in the field of preparation of nano-silver antibacterial fabrics, can solve the problems of making nano-silver microcapsule finishing agents, and achieve the effects of good appearance, simple operation, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

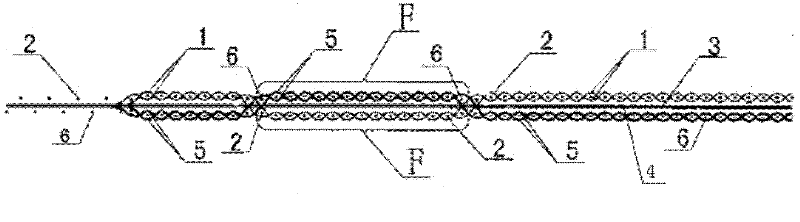

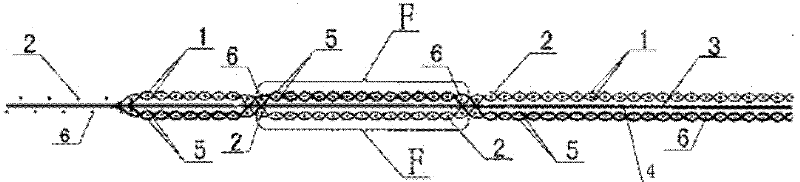

Image

Examples

Embodiment 1

[0027] The following components are formulated according to mass percentages as follows: nano silver 10Kg, adhesive-107 glue 11Kg, polyurethane 3Kg, softener-organic silicon 3Kg, microcapsule solution 20Kg, dispersant-ZD 3Kg, water 40Kg , a total of 100Kg.

[0028] At 35°C, put 10Kg of nano-silver into 3Kg of polyurethane and 40Kg of water, stir at a speed of 1500 rpm for 1 minute, add the microcapsule solution and stir until it becomes an emulsion, then add 3Kg of ZD in turn Finally, stir for 1-3 minutes, add 11Kg of 107 glue, stir for 5 minutes, then add 3Kg of organic silicon and stir for 3 minutes to make a nano-silver microcapsule finishing agent for use;

[0029] The pure cotton yarn of JC18tex was dipped and rolled twice in the microcapsule finishing agent, and the yarn was taken out, wherein the liquid-carrying rate of the yarn was 100%. The yarn padded in the microcapsule finishing agent is pre-baked at 80°C for 3 minutes and then qualitatively baked at 140°C for 3 m...

Embodiment 2

[0032] The following components are dosed according to mass percentage as follows: nano silver 15Kg, adhesive-107 glue 15Kg, polyurethane 3Kg, softener-organic silicon 4Kg, microcapsule solution 20Kg, dispersant-ZD3Kg, water 30Kg, A total of 100Kg.

[0033] At 40°C, put 15Kg of nano-silver into 3Kg of polyurethane and 30Kg of water, stir for 2 minutes at a speed of 1700 rpm, add the microcapsule solution and stir until it becomes an emulsion, then add ZD in turn After 3Kg, stir for 1-3 minutes, add 15Kg of 107 glue, stir for 5 minutes, then add 4Kg of organic silicon and stir for 3 minutes to prepare a nano-silver microcapsule finishing agent for use;

[0034]The regenerated cellulose fiber yarn of 20tex is sprayed with microcapsule finishing agent, and the yarn is taken out, wherein the coverage rate of the yarn is 100%. The yarn sprayed with microcapsule finishing agent was pre-baked at 100°C for 5 minutes and then qualitatively baked at 160°C for 5 minutes to obtain regene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com