Method for mining coal and gas by hydraulic jet grouting washout

A hydraulic and coalbed methane technology, applied in drilling equipment and methods, mining fluids, mining equipment, etc., can solve problems such as economic loss, casualties, environmental impact, etc., achieve cost savings, suppress dust flying, and improve underground operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

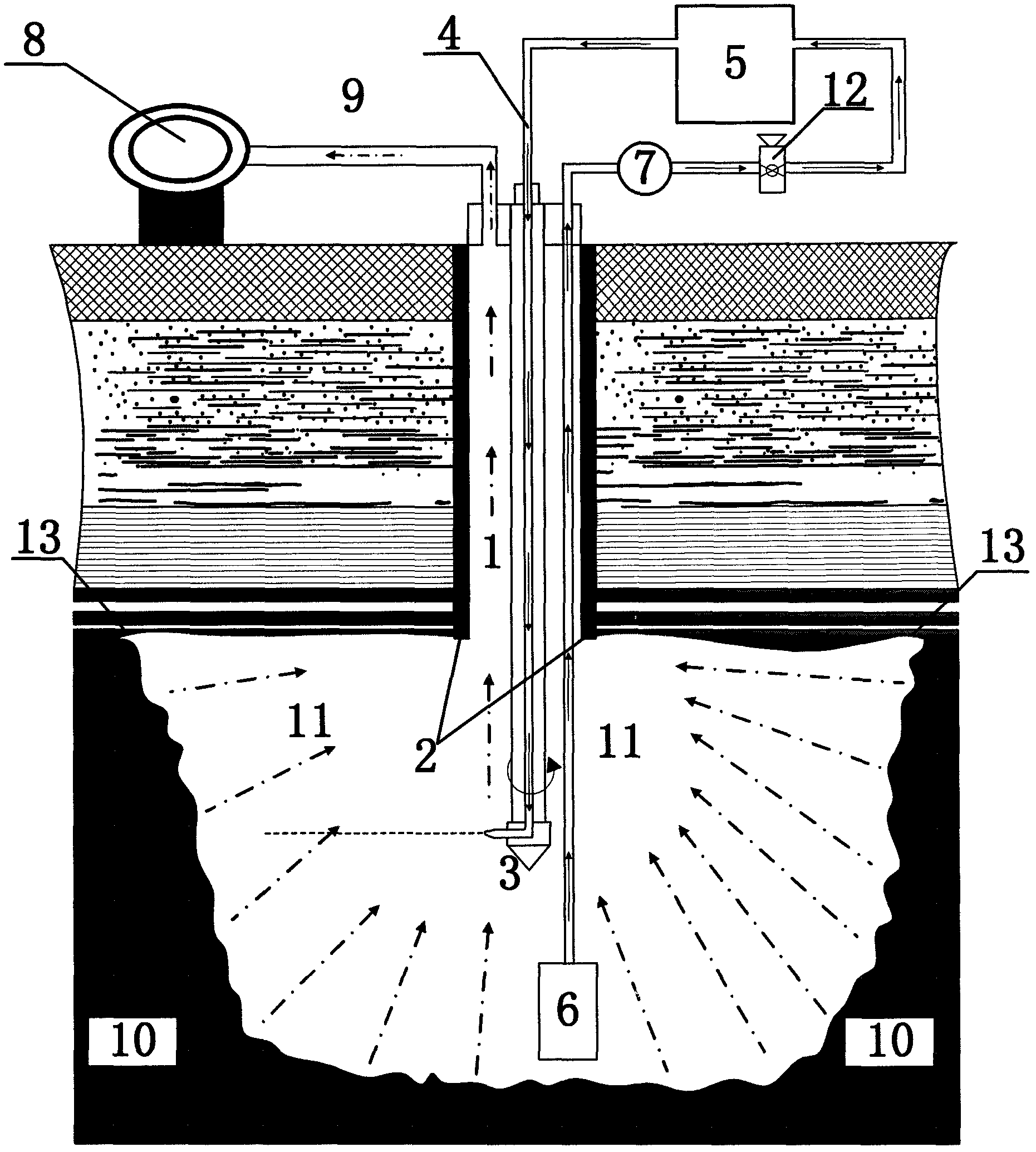

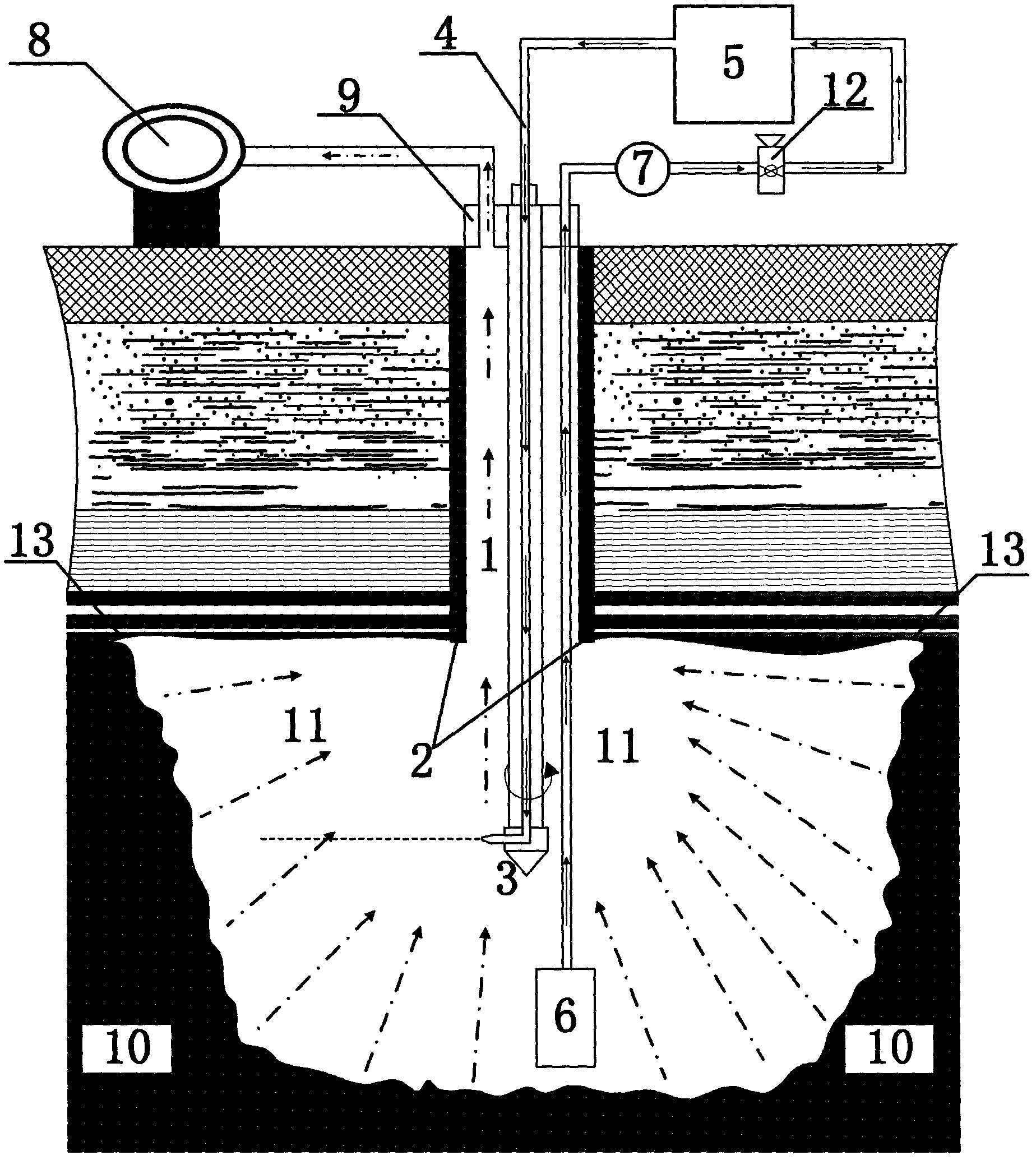

[0022] The following invention will combine figure 1 For further description:

[0023] If shown, the present invention is a hydrojet coal gas recovery method, comprising the following steps:

[0024] (1) Set the coalbed methane production well 1. Use a large-diameter drilling rig to excavate a large-caliber drilling well into the coal seam 10 to a predetermined depth, set up a coalbed methane production well 1 capable of water injection, drainage, and gas output, and install a casing 2 around the production well 1 to the coal seam roof 13, and the casing 2 and the coal seam roof 13 The geological layers above the coal seam 10 are fixedly connected by known methods.

[0025] (2) mechanical hole digging. After the coalbed methane production well 1 is completed, use the existing mechanical digging tool to carry out the digging operation at the bottom of the gas production well 1 corresponding to the coal seam 10, the depth is a predetermined depth, and can accommodate the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com