Engine exhaust parameter detecting device for matching muffler with engine

A parameter detection and engine technology, which is applied in the direction of machines/engines, electronic control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve problems such as unavailable and difficult to obtain successful applications, and achieve accurate and fast measurement , Convenient simulation and matching design, accurate and convenient to obtain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

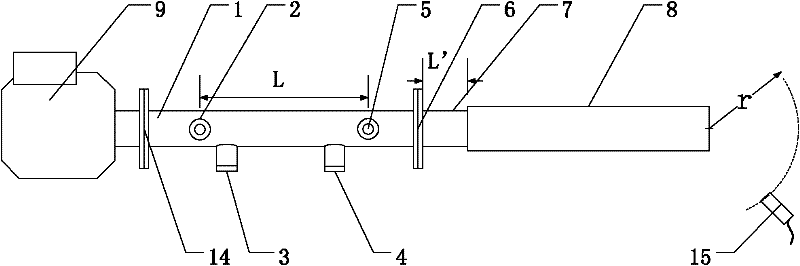

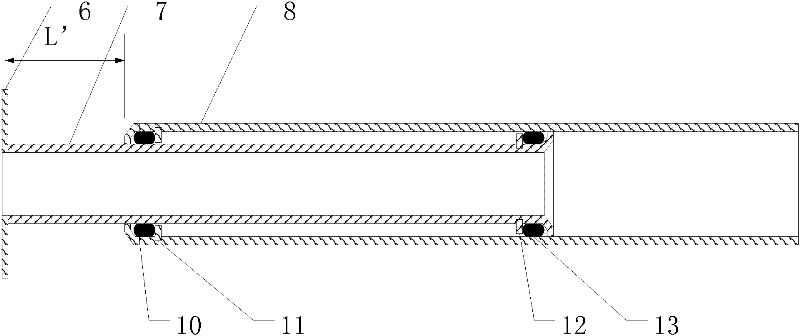

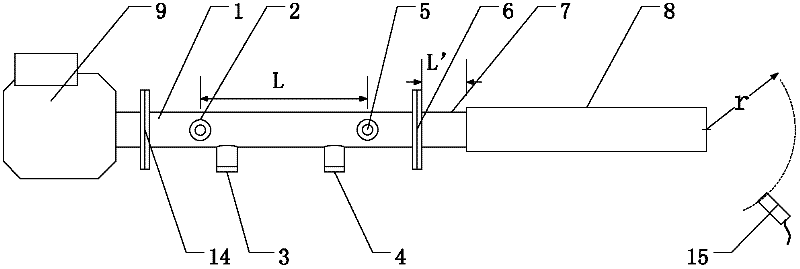

[0009] The engine exhaust parameter detection device for matching the muffler with the engine proposed by the present invention has a structure such as figure 1 As shown, including the measuring tube 1 and the acoustic load change tube. The acoustic load change tube is composed of an inner tube 7 and an outer tube 8, one end of the measuring tube 1 is connected to the exhaust manifold of the engine 9 through the front connecting flange 14, and the other end of the measuring tube 1 is connected through the rear connecting flange 6 It is connected with the inner tube 7 described above. The measuring tube 1 is provided with a first dynamic pressure sensor mount 2, a second dynamic pressure sensor mount 5, a static pressure sensor mount 3 and a thermocouple mount 4, the first dynamic pressure sensor mount 2 and the second dynamic pressure sensor The distance between the sensor mounts 5 is L, and the value range of L is 300 mm to 500 mm. The static pressure sensor mount 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com