Composite swirl combustion chamber

A technology of combustion chambers and composite rolls, applied in combustion engines, internal combustion piston engines, machines/engines, etc., can solve problems such as low air utilization, poor oil-gas mixing, and reduced fuel injection penetration, and achieve fuel distribution expansion, The effect of high air utilization rate, mixing and accelerated combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

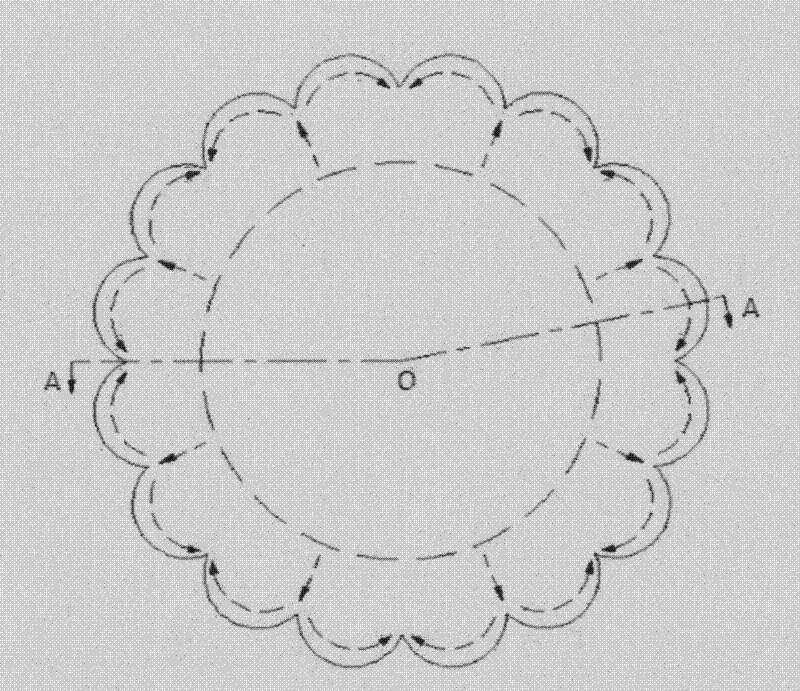

[0038] The CFD three-dimensional mesh models of the composite plume combustor, ω combustor, double plume combustor and side plume combustor under the same compression ratio were respectively established for simulation calculation comparison. Among them, the structures of the basic double-plume combustor, ω combustor, double-plump combustor and side swirl combustor are determined by parametric design.

[0039] The design parameters and calculation settings of the combustion chamber are: eight-hole fuel injector is suitable, the cylinder diameter is 132mm, the stroke is 145mm, the connecting rod length is 262mm, and the clearance height is 2.5mm.

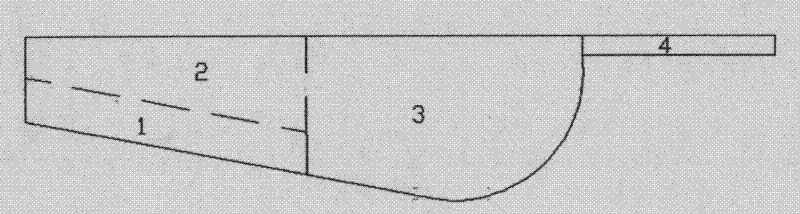

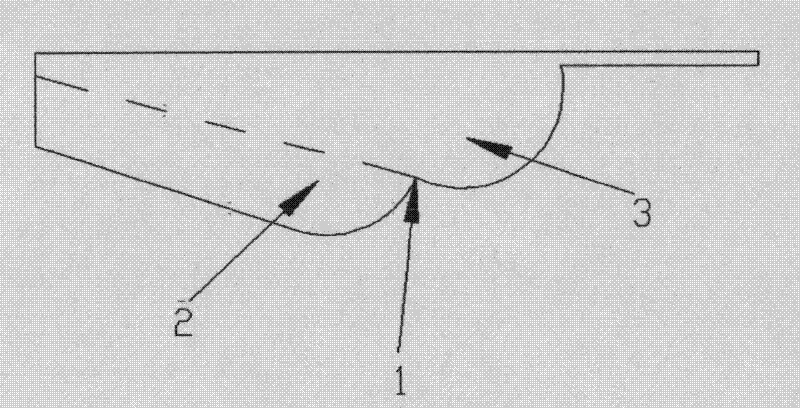

[0040] Calculated according to the compression ratio of 13.5, the volume of the compound plume combustion chamber should be 107510mm 3 . The actual modeling volume is 106506mm 3 , with a deviation rate of 0.93%. In terms of geometric dimensions, the center cone angle is 119°, the cone point height is 5.4mm, the depth of the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com