Distributed image high power tube core

A high-power, decentralized technology, applied in the direction of improving amplifiers to improve efficiency, electrical components, electrical solid-state devices, etc., can solve problems such as increased circuit complexity, single chip output power limitation, and reduced efficiency, to improve uniform heat dissipation performance, avoiding local hot spots, and good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

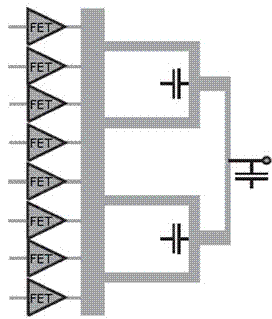

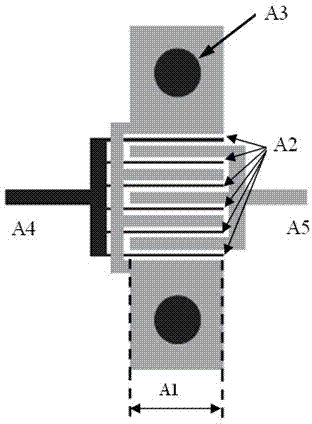

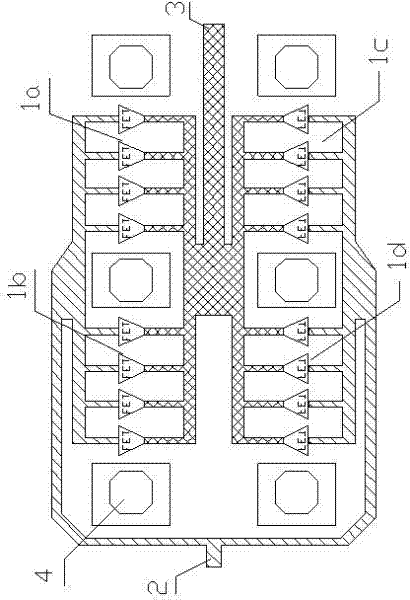

[0025] image 3 It is an eight-way synthesis design of dual rank dies according to the embodiment of the present invention. Among them, 1a, 1b, 1c, and 1d are HEMT unit cells, and each unit cell contains 6 FETs; each unit cell is isolated by the source bar through hole 4, and the heat source is evenly separated while the HEMT source is grounded. , to avoid excessive concentration of heat in the middle. HEMT unit cells 1a and 1b are arranged in the same direction, HEMT unit cells 1c and 1d are arranged in the same direction, HEMT unit cells 1a and 1c are mirror-symmetrically distributed, and HEMT unit cells 1b and 1d are mirror-symmetrically distributed. At the same time, the HEMT unit cells 1a, 1b, 1c, and 1d as a whole and the HEMT unit cells 1a', 1b', 1c', and 1d' are mirror-symmetrically distributed on the basis of the center line in the figure. 2 in the figure is the microwave signal input power distribution network, which evenly distributes the microwave signal to each ...

Embodiment 2

[0027] Figure 5 It is an eight-way synthesis design of four columns of dies in the embodiment of the present invention. This embodiment adopts a four-column die layout design, which reduces the vertical size of the chip by half under the premise of the same gate width; the same vertical size of the chip can double the total gate width and greatly increase the output power of a single chip. 1a-1h in the figure are HEMT unit cells. HEMT unit cells 1a~1d are arranged in the same direction, HEMT unit cells 1e~1h are arranged in the same direction, HEMT unit cell 1a and HEMT unit cell 1e are mirror images of each other, HEMT unit cell 1b and HEMT unit cell 1f are mirror images of each other The HEMT unit cell 1c and the HEMT unit cell 1g are in a mirror image relationship with each other, and the HEMT unit cell 1d and the HEMT unit cell 1h are in a mirror image relationship with each other. 2 in the figure is the input power distribution network, which evenly distributes the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com