Polymer device with driving and sensing capability, preparation thereof and application thereof

A sensing and functional technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problems of low actuation ability of PVDF, To achieve the effect of improving the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

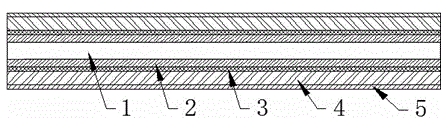

[0085] The first step is to prepare the ion exchange layer 1:

[0086] Ion exchange solution: Nafion DE520cs, curing agent dimethylsulfoxide (DMSO), glass mold volume size 10cm×10cm×10cm.

[0087] To prepare a 0.4 mm ion exchange layer, put a glass mold containing 112 ml of Nafion solution into a vacuum drying oven, control the temperature of the vacuum drying oven at 60° C., and dry the solution to a concentration of 30%. Add DMSO dropwise into the solution (volume ratio: DMSO:Nafion=1:35) to form a film-casting liquid, and put the film-casting liquid into an ultrasonic cleaning machine to vibrate for about 30 minutes. Place the casting solution in an oven at 55°C until the surface of the film is dry, raise the temperature of the oven to 110°C and keep it for 1 hour, then raise the temperature to 130°C and keep it for 4 hours, turn off the oven, and let it cool down to room temperature naturally.

[0088] The second step is to prepare the transition electrode layer 2:

[00...

Embodiment 2

[0105] The first step is to prepare the ion exchange layer 1

[0106] Raw materials: ion exchange solution: Nafion DE520cs, curing agent dimethyl sulfoxide (DMSO), glass mold volume size 10cm×10cm×10cm, and prepare 0.2mm ion exchange layer.

[0107] Put the glass mold filled with 56 milliliters of Nafion solution into a vacuum drying oven, control the temperature of the vacuum drying oven to be 55° C., and bake the solution to a concentration of 25%. Add DMSO dropwise to the solution (volume ratio: DMSO:Nafion=1:40) to form a film-casting liquid, and put the film-casting liquid into an ultrasonic cleaning machine to vibrate for about 25 minutes. Put the casting solution in an oven at 55°C until the surface of the film is dry, raise the temperature of the oven to 100°C and keep it for 1.5 hours, then raise the temperature to 120°C and keep it for 3 hours, turn off the oven, and let it cool down to room temperature naturally.

[0108] After taking it out, cut it into a strip-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com