High-power ASE (Amplified Spontaneous Emission) light source with multi-section cascade 1064nm wave bands

A high-power, cascaded technology, applied in the field of light sources, can solve the problems of affecting the mechanical properties of optical fibers, unstable output power, isolation index and limited working bandwidth, etc., to filter out useless ASE light and increase the output power level , Reduce the effect of photodamage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described and explained below in combination with specific implementation examples and accompanying drawings, but is not limited to this implementation mode.

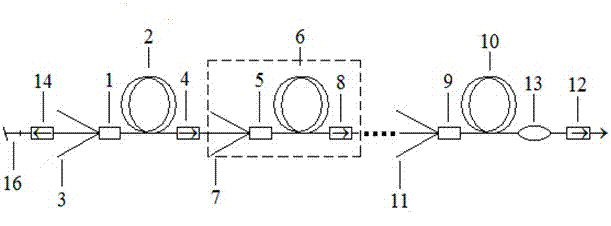

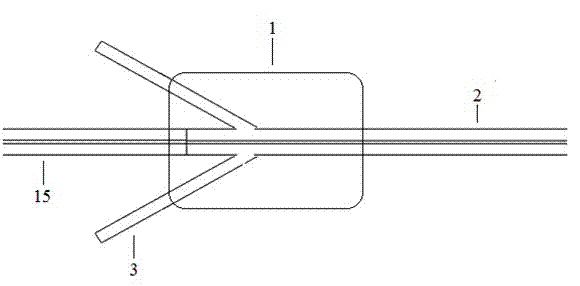

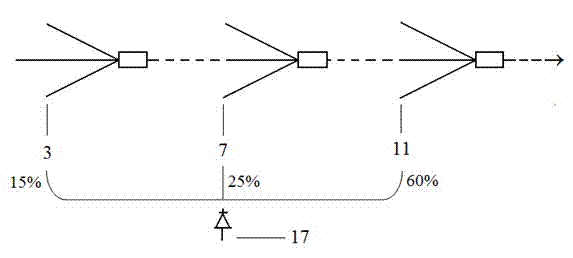

[0031] Such as figure 1 As shown, the multi-segment cascaded 1064nm band high-power ASE light source includes n-segment cascaded structures, and each segment of the cascaded structure includes sequentially connected active beam combiners (1, 5, 9), active double-pack Layers of optical fibers (2, 6, 10) and optical isolators (4, 8, 12), the output end of the optical isolator in the first cascade structure is connected to the input end of the active beam combiner in the second cascade structure; A section of cascade structure includes the first-stage active beam combiner 1, the first section of active double-clad fiber 2 and the first optical isolator 4. In the n-section cascade structure, the n-section active double-clad fiber A cladding mode filter 13 is connected between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com