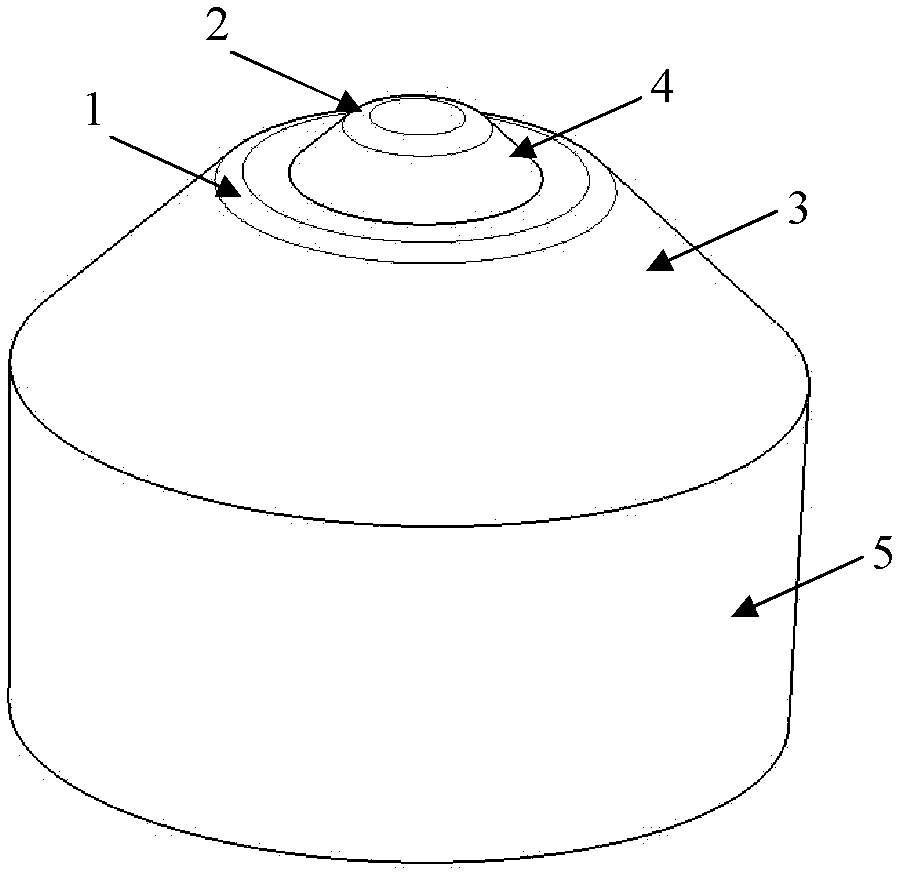

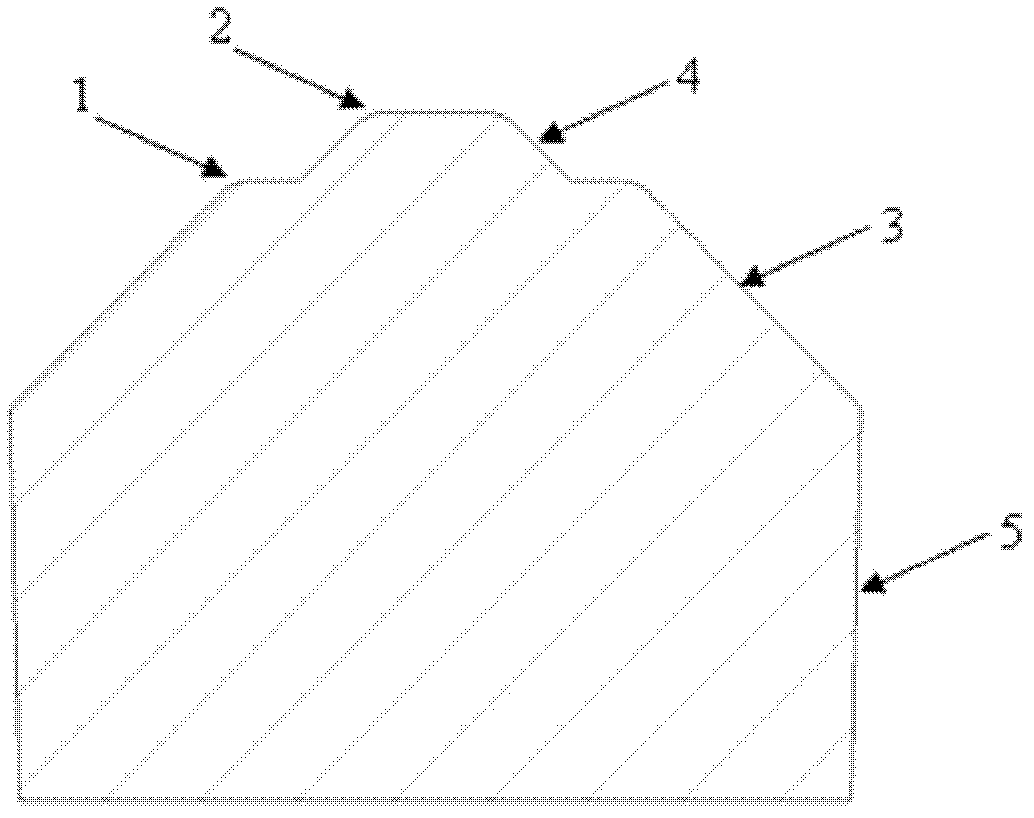

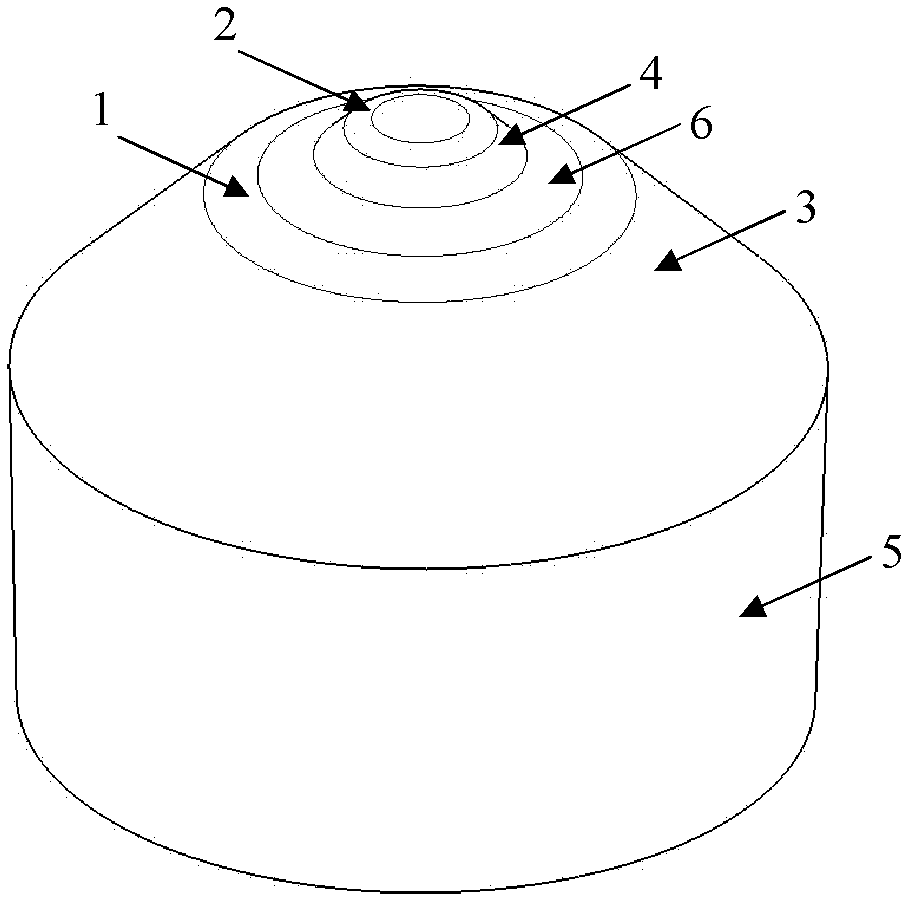

Multi-stage filleted high-pressure anvil

A technology of rounded corners and anvils, applied in the process of applying ultra-high pressure, can solve the problems of not meeting research needs, small cavity volume, low cavity pressure, etc., achieving less investment, simple operation, and increased cavity effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027]In order to solve the problem of extreme conditions (high temperature and high pressure), the high-pressure anvil used in conjunction with the anvil device, two-sided high-pressure device, four-sided high-pressure device, six-sided high-pressure device and multi-stage supercharging device has a simple structure with corners. There are problems such as low service life, low cavity pressure and small cavity volume, which cannot meet the research needs of high-pressure physics, geophysics, materials science and high-pressure biology for material systems under ultra-high pressure. The present invention is achieved through the following technical solutions: the present invention provides a multi-stage rounded high-pressure anvil, which for the first time breaks the traditional anvil's corner and first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com