Magnetic adsorbent and preparation method thereof

An adsorbate and magnetic technology, applied in the fields of inorganic material magnetism, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of unrecoverable valence metals, high waste water treatment costs, waste of resources and treatment time, etc. Achieve the effect of avoiding sludge disposal problems, reducing treatment costs and shortening treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

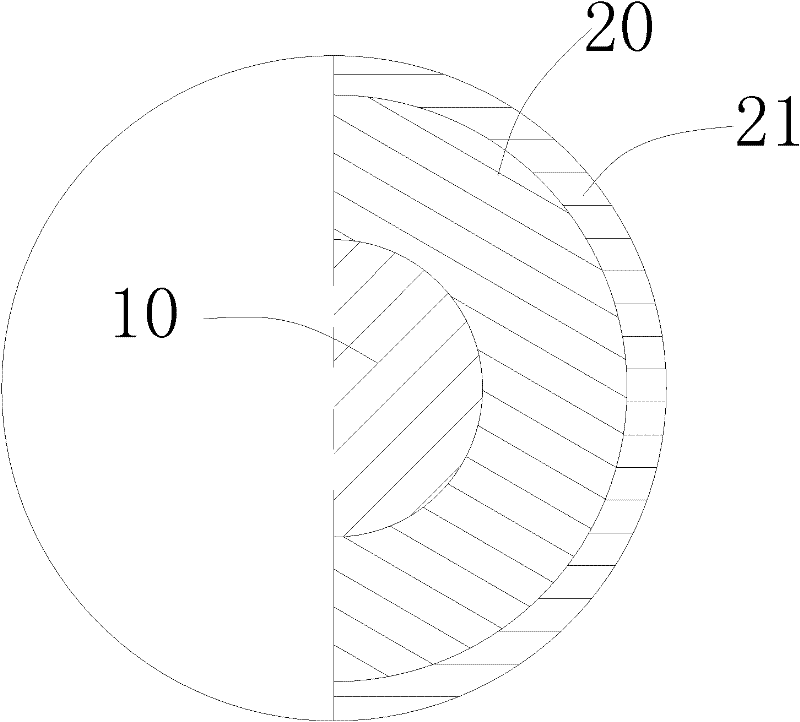

[0040] refer to figure 1 , a magnetic adsorbent provided by an embodiment of the present invention, which is mainly composed of a carrier 10 covered by a shell 20, wherein:

[0041] Carrier 10 has magnetism, and carrier 10 is triiron tetroxide (Fe 3 o 4 ), which is mainly ferrous chloride (FeCl 2 ) and ferric chloride solution (FeCl 3 ) produced by mixed precipitation;

[0042] The shell 20 is covered on the outside of the carrier 10, and the outside of the shell 20 has an adsorption layer 21, wherein the shell 20 is silicon dioxide (SiO 2 ), the adsorption layer 21 is modified with amine groups, so that the adsorption layer 21 has a covalently bonded amine functional group, which has the ability to strongly bind to copper ions.

[0043] The above is the description of the structure of the adsorbate in the embodiment of the present invention. Accordingly, the magnetic adsorbate provided by the present invention has at least the following effects.

[0044] First, the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com