Aging method and equipment of catalytic cracking catalyst

A catalytic cracking and catalyst technology, used in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of catalyst deactivation, high catalyst activity, uneven catalyst activity reduction, etc. Effects of coke yield, increased gasoline octane number, and improved product distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

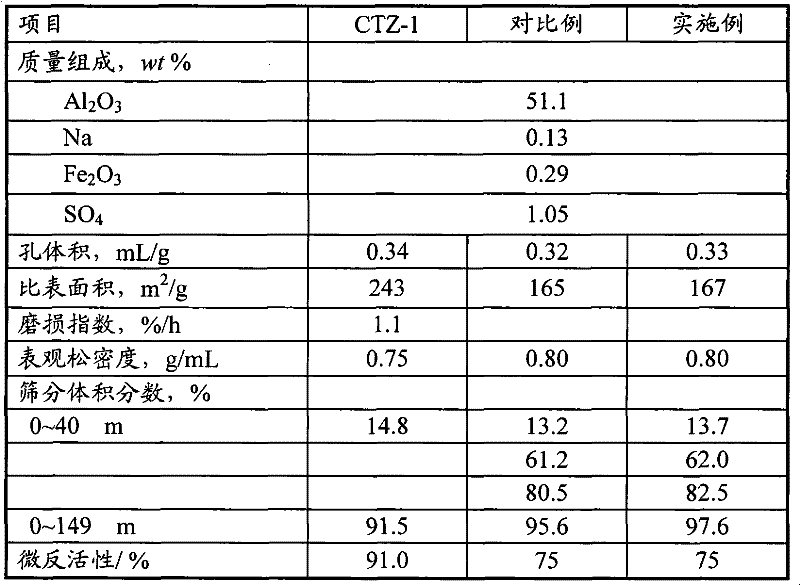

[0036] The examples illustrate the catalytic cracking catalyst aging method provided by the present invention.

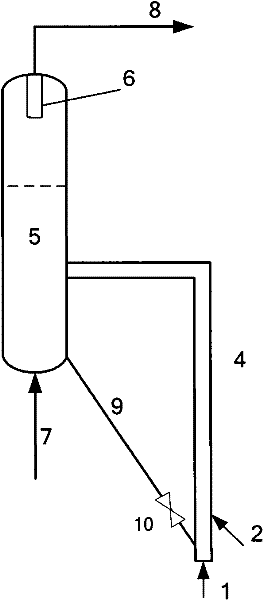

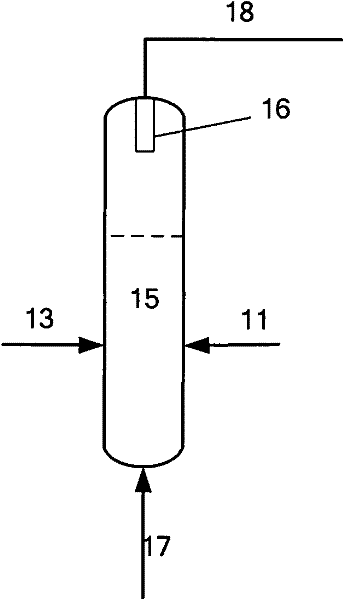

[0037] as attached figure 1As shown, the catalyst aging device has a diameter of 260mm and a height of 4m; the dilute phase burner has a diameter of 10mm and a height of 3m. First put the fresh catalytic cracking catalyst into the catalyst aging device 5, inject the water vapor from the pipeline 7 into the bottom of the catalyst aging device and contact the catalyst for hydrothermal reaction to reduce the activity of the catalyst, the gas in the catalyst aging device 5 and the catalyst it carries The top of the aging device is separated by the filter 6, and the gas enters the subsequent treatment system through the pipeline 8; the separated catalyst returns to the bottom of the aging device, and the catalyst extracted from the bottom of the aging device enters the bottom of the dilute phase burner 4 through the pipeline 9 and the control valve 10, and The air from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com