Preparation method for haze-adjustable flexible transparent conductive film

A transparent conductive film, flexible technology, applied in the device, ink, special surface and other directions of coating liquid on the surface, can solve the problems of expensive, unfavorable formation of patterns and circuits, and high preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

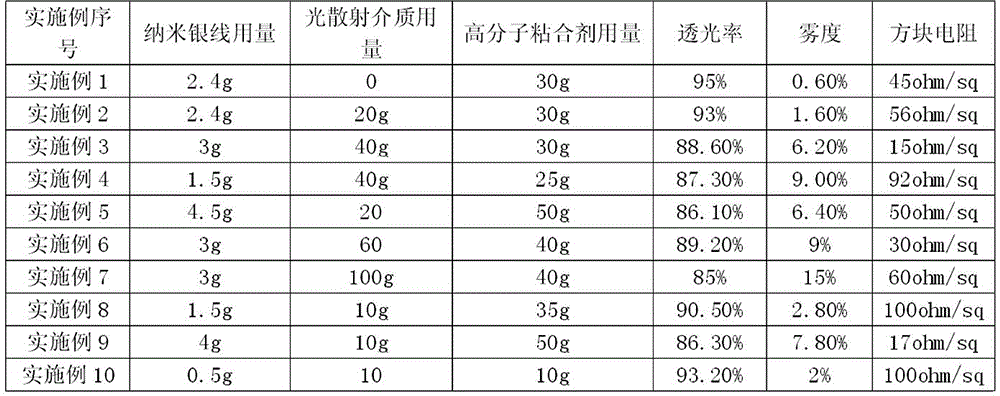

Embodiment 1

[0033] 1) Preparation of silver nanowire ink without light scattering medium:

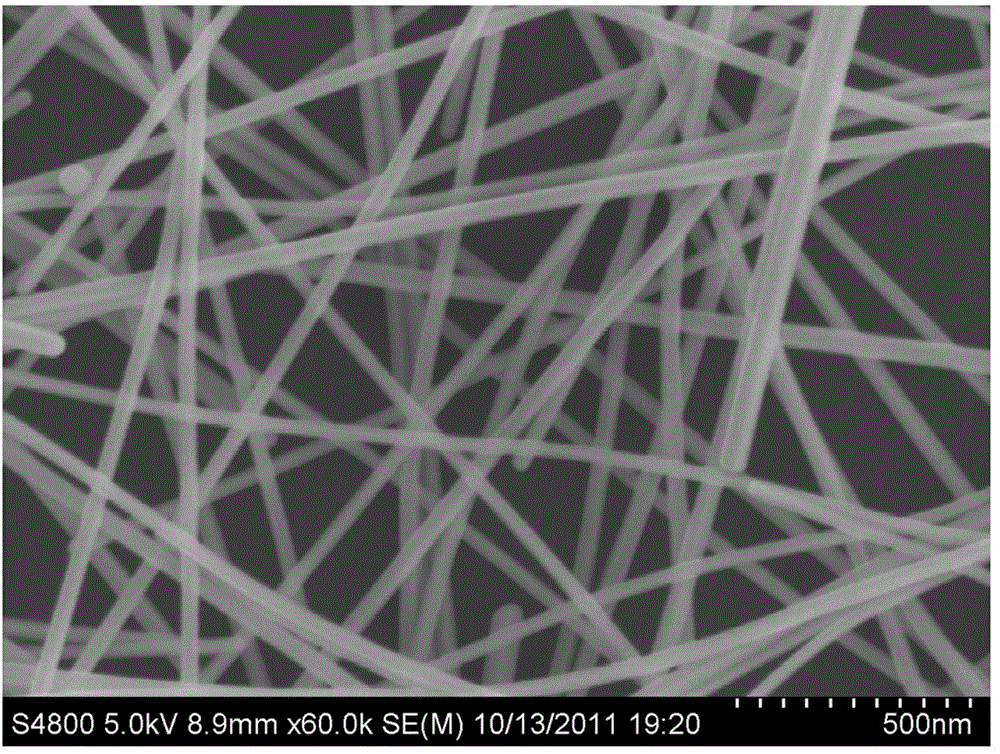

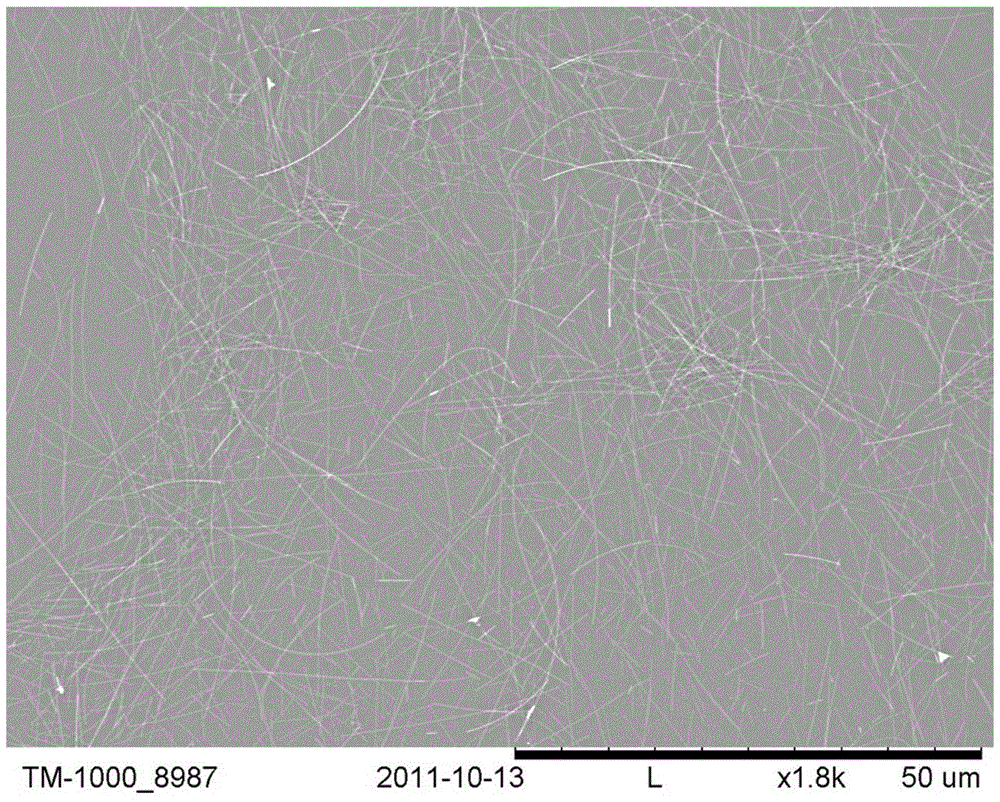

[0034] Add 250g of solvent ethanol to a 500mL three-necked flask with a stirrer, then add a mixture of 30g of epoxy resin adhesive and 100g of acetone, 120g of nano silver wire ethanol solution (the concentration of nano silver wire solution is 2.0%), nano The silver wire has an average diameter of 35nm, an average length of 15μm, and an aspect ratio of over 400. Stir for 30 minutes, and after mixing evenly, the silver nanowire ink is prepared. In the prepared silver nanowire ink, the concentration of silver nanowires is 0.48%.

[0035] 2) Preparation of transparent electrodes and performance testing

[0036] The corona-treated PET was used as a transparent substrate (visible light transmittance 91.8%), and the silver nanowire ink prepared in step 1 was used to form a uniform film layer on the substrate by spin coating. Bake at 150° C. for 30 minutes to cure the polymer adhesive on the surface to...

Embodiment 2

[0038] 1) Preparation of silver nanowire ink:

[0039] Add 200g of solvent ethanol to a 500mL three-necked flask with a stirrer, then add a mixture of 30g of epoxy resin adhesive and 100g of acetone, 50g of methanol solution (concentration of 40%) of nano-silver powder with a diameter of 50nm, nano Silver wire ethanol solution 120g (the concentration of nano silver wire solution is 2.0%), the average diameter of nano silver wire is 35nm, the average length is 15μm, and the aspect ratio exceeds 400. After stirring for 30 minutes, the silver nanowire ink was prepared after mixing evenly. In the prepared silver nanowire ink, the concentration of the silver nanowires was 0.48%, and the concentration of the light scattering medium was 4%.

[0040] 2) Preparation of transparent electrodes and performance testing

[0041] The corona-treated PET was used as a transparent substrate (visible light transmittance 91.8%), and the silver nanowire ink prepared in step 1 was used to form a u...

Embodiment 3

[0043] 1) Preparation of silver nanowire ink:

[0044] Add solvent ethanol 120g in the 500mL there-necked flask with agitator, then add the mixed solution of epoxy resin binder 30g and acetone 100g, 100g diameter is the n-butanol solution of the nanometer copper powder of 100nm (concentration is 40%) ), 150g of nano-silver wire ethanol solution (the concentration of nano-silver wire solution is 2.0%), the average diameter of nano-silver wire is 20nm, the average length is 5μm, and the aspect ratio is 250. After stirring for 30 minutes, the silver nanowire ink was prepared after mixing evenly. In the prepared silver nanowire ink, the concentration of the silver nanowires was 1.2%, and the concentration of the light scattering medium was 8%.

[0045] 2) Preparation of transparent electrodes and performance testing

[0046] Using corona-treated polycarbonate as a transparent substrate (visible light transmittance 91.8%), the silver nanowire ink forms a uniform film layer on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com