Process and production line of spraying, homogenizing and drying in double-tube

A drying process and internal spraying technology, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc., can solve the problems of poor connection of pipeline transmission, low production efficiency, and collision equipment, etc., to improve production efficiency and operation Simple, collision-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

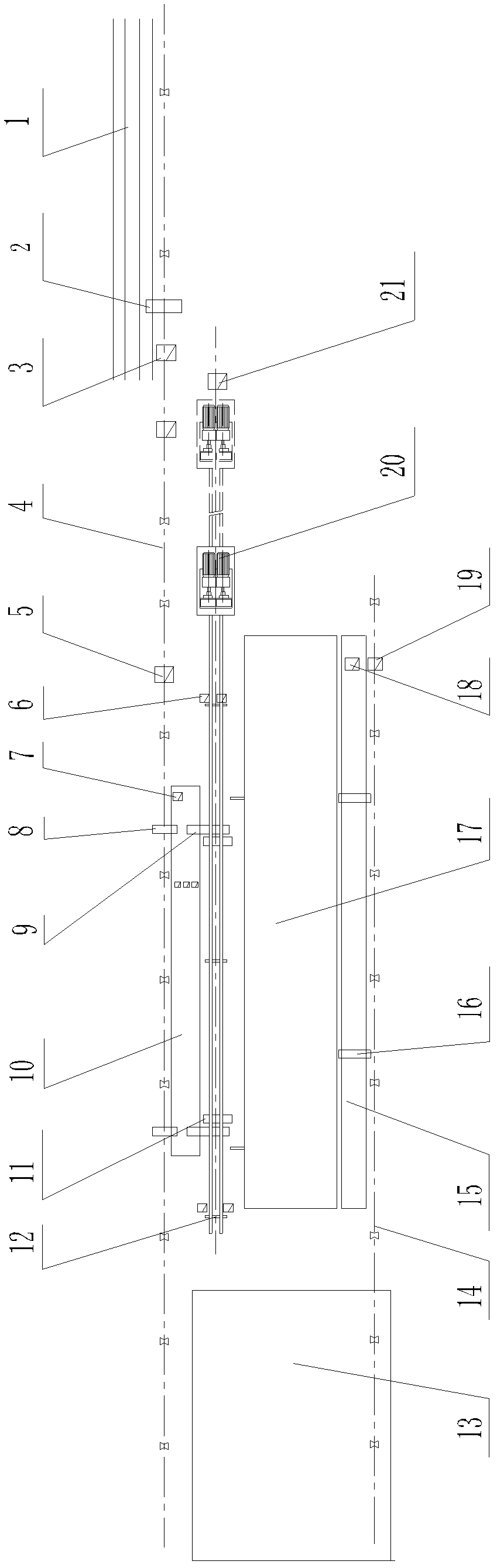

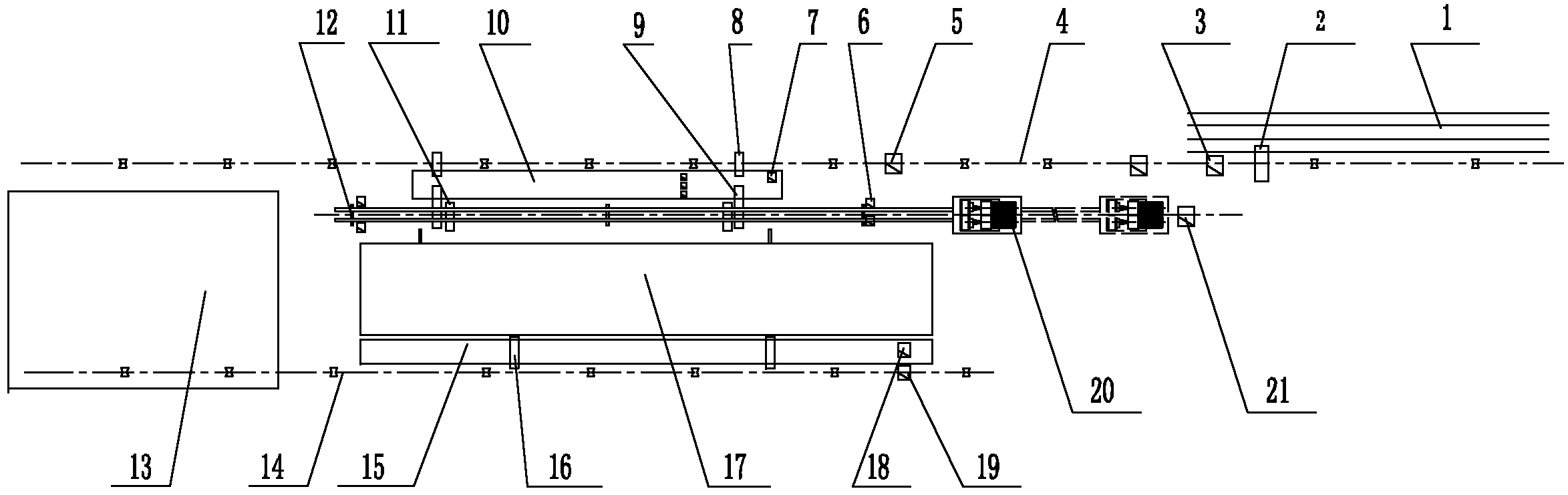

[0016] Below in conjunction with accompanying drawing, invention will be further described:

[0017] The process of spraying homogeneous drying in double pipes of the present invention comprises the following steps:

[0018] ①Pipe loading process: first move the pipeline to be sprayed from the loading rack to the predetermined position through the transmission line, and then lift it to the transition frame;

[0019] ②Double-pipe lifting process: When there are two pipelines on the transition frame, they are lifted to the spraying frame at the same time;

[0020] ③Double-gun spraying process: The spraying vehicle is moved to spray the double-pipes at the same time with two guns to carry out anti-corrosion spraying on the inner holes of the double-pipelines. After the spraying is completed, the spraying vehicle returns;

[0021] ④ Homogenization process: lift the sprayed pipeline to the homogeneous frame, and the homogeneous frame drives the sprayed pipeline to rotate, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com