Soil remediation system

A soil remediation and soil technology, which is applied in the field of soil remediation systems, can solve problems such as system complexity, and achieve the effect of simple system composition, easy operation, and low content of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

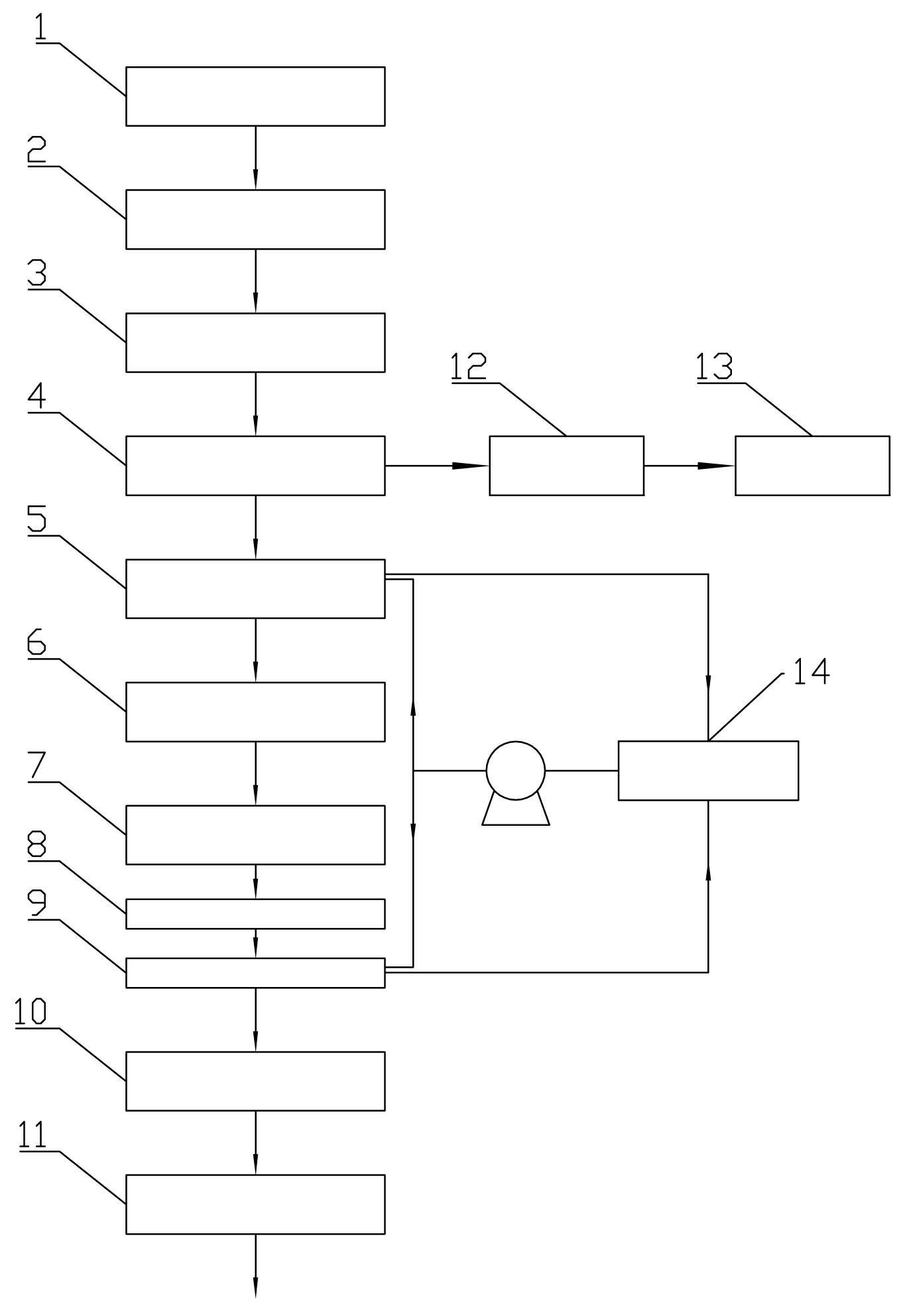

[0024] like figure 1 As shown, a soil remediation system includes a primary screw conveyor 1, a vibrating screen 2, a secondary screw conveyor 3, a thermal analysis furnace rotary kiln 4, a tertiary screw conveyor 12, a crusher 13, and a first water condensation 5, cyclone dust collector 6, incinerator 7, gas condenser 8, second water condenser 9, bag filter 10, induced draft fan 11, cooling tower 14; where:

[0025] The primary screw conveyor 1 transports the soil to be treated to the vibrating screen 2;

[0026] The secondary screw conveyor 3 transports the sieved soil to the rotary kiln 4 of the thermal desorption furnace;

[0027] The thermal analysis furnace rotary kiln 4 heats and analyzes the soil;

[0028] The three-stage screw conveyor 12 transports the heated and analyzed soil to the crusher 13 for crushing;

[0029] The first water condenser 5 cools the 500-600°C waste gas discharged from the thermal desorption furnace rotary kiln 4 to 280-320°C;

[0030] The cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com