High-strength high-ductility submerged-arc welding wire

A submerged arc welding wire, high-strength technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve the effect of excellent comprehensive mechanical properties, low cost, and simple composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

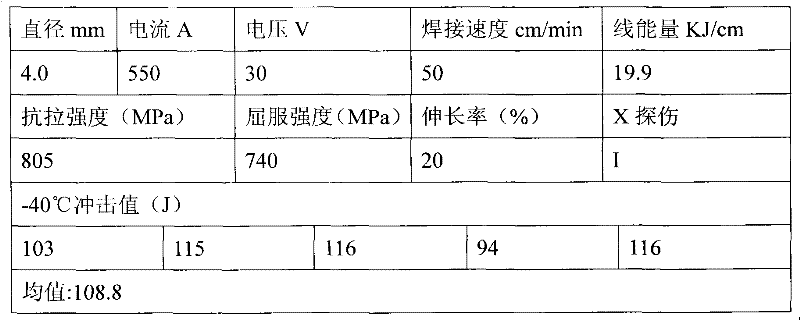

[0005] The deposited metal with excellent comprehensive mechanical properties is obtained by using the submerged arc welding wire of the embodiment of the present invention and welding with SJ606 flux. We require steel mills to provide 6.5mm hot-rolled wire rods according to the set welding wire composition requirements. Our company finally makes 4.0mm submerged arc welding wires through drawing and copper plating. The chemical components of the welding wires are listed in Table 1. The preparation of the welding wires is in the existing Manufactured under equipment and technical conditions. The test plate for welding is Q690, with a thickness of 20mm; the size of the welding groove, sampling position and test method are all in accordance with the national standard GB / T 12470. The test results are listed in Table 2.

[0006] Table 1

[0007] Numbering

C

mn

Si

Cr

Ni

Mo

S

P

1

0.062

1.83

0.545

0.45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com