Integrated micro-valve droplet control chip and method for synthesizing and assembling polymer microspheres

A polymer, chip technology, used in microstructure devices, manufacturing microstructure devices, processes for producing decorative surface effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0042] Example 1

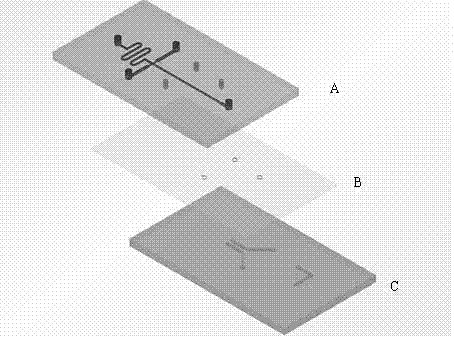

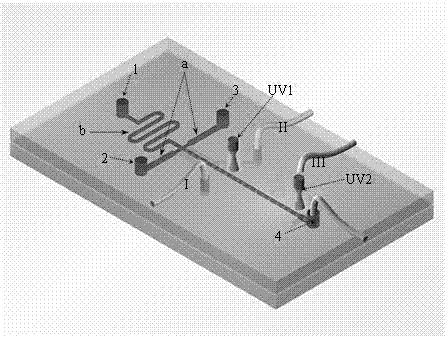

[0043] The number control and bonding angle control of the experimental microsphere assembly was carried out by using figure 2 The structure of the chip shown is that the chip is composed of upper, middle and lower layers; among them, the upper layer is a liquid channel chip, which is composed of a liquid reservoir, a water phase channel and an oil phase channel; the middle layer is a thin film layer; the lower layer is a gas control chip. access chip; and the integrated microvalve is composed of liquid circuit, film and gas circuit control, and the material of the upper layer of the chip, the material of the middle film and the lower layer are all PDMS; then add 20ul mineral oil (4% span80 ), add 10ul NOA61 (including 10 5 M Rhodamine B), the reservoir 4 is connected to a syringe pump and pumped at a constant flow rate (0.6ul / mi...

Embodiment 2

[0045] Test the assembly of microparticles with a specific internal size sequence, taking the assembly of 2 large balls (A) and 2 small balls (B) as an example, there are 3 theoretical size sequences: A-B-A-B, A-A-B-B and A-B-B-A (see Figure 12 ). Using the method described in Example 1, according to Figure 12 Line 1, Line 2, and Line 3 shown in , form the corresponding droplet sequence (see Figure 13 middle row), and under the action of ultraviolet light, microparticles with a specific size sequence that exactly match the model are formed (see Figure 13 ). If assembled with 4 microspheres of different sizes (A, B, C, D), theoretically there are about 4 4 / 2 different size sequences, one of which is a sequence of sizes such as Figure 14 shown.

Embodiment 3

[0047] To test the assembly of microparticles with a specific internal composition sequence, add 10 ul NOA61 (containing 10 5 M Rhodamine B), add 10 ul NOA61 (containing 10 5 M rhodamine 123) (see Figure 15-1 ), using the method described in Example 1, to form microspheres (E and F) with 2 different components. Taking the assembly of 2 E balls and 2 F balls as an example, there are three theoretical composition sequences: E-E-F-F, E-F-E-F and E-F-F-E (see Figure 15-2 ). Using the method described in Example 1, according to Figure 15-2 The sequence of lines 1, 2, and 3 shown in Figure 1 produces a droplet sequence corresponding to the composition, and under the action of ultraviolet light, microparticles with a specific composition sequence that are completely consistent with theoretical predictions are formed (see Figure 15-3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com