Integrated bubbleless aeration membrane bioreactor

A membrane bioreactor, bubble-free aeration technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of unreasonable membrane structure, high cost, defects of material-liquid mixing device, etc., and achieve convenient and accurate control The effect of aeration volume, convenient operation, and easy flow rate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

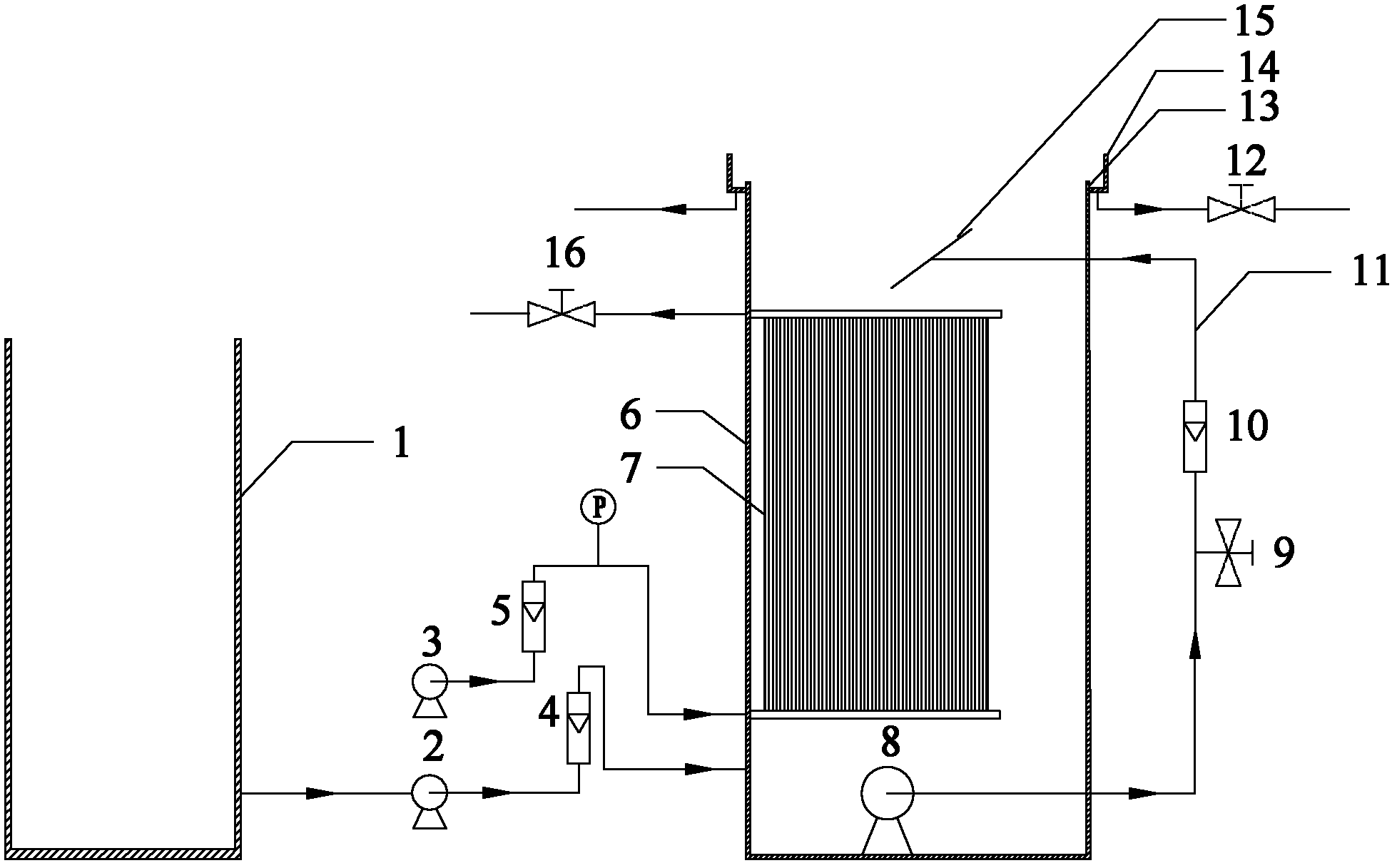

[0026] refer to figure 1 , an integrated non-bubble aerated membrane bioreactor, which is provided with a biochemical reactor 6, and a hollow fiber curtain membrane 7 is vertically placed in the biochemical reactor 6, and the hollow fiber curtain membrane 7 is made of hydrophobic polyvinylidene fluoride Vinyl material. The upper and lower ends of the hollow fiber curtain membrane 7 are respectively fixed in the side wall of the single-pass PVC pipe with resin, the PVC pipe at the lower end of the hollow fiber curtain membrane 7 is connected with the air intake pipe, and the PVC pipe at the upper end of the hollow fiber curtain membrane 7 It is connected with the exhaust pipe, the intake pipe is connected with the air compressor 3 through the air rotameter 5, and the exhaust pipe is passed into the air through the gas fine-tuning valve 16. Also be provided with submersible pump 8 at the bottom of biochemical reactor 6, submersible pump 8 is connected with outer circulating pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com