Process and equipment for processing pesticide wastewater

A pesticide wastewater and treatment process technology, applied in natural water treatment, extraction water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as decreased membrane stability, reduced mass transfer driving force, and reduced solute extraction rate

Active Publication Date: 2013-10-30

蓝星工程有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the ELM system complicates the process due to the introduction of surfactants. It must be composed of three processes: milk making, extraction, and demulsification. The membrane leakage of ELM reduces the extraction rate of solutes, and the liquid due to entrainment and osmotic pressure difference The swelling of the membrane leads to the dilution of the concentrated solute in the internal phase, the reduction of the mass transfer driving force and the decrease of the membrane stability. In addition, there are problems such as the incomplete separation of the aqueous phase and the extraction phase after the demulsification, which limits its The successful application of

At present, there is no effective treatment of 2,4-D production wastewater, and there is no process technology to achieve zero discharge. In this patent, the recovery of valuable materials and quasi-zero discharge are realized by using the supporting liquid membrane as the main body and combining adsorption and membrane separation technology. Emissions to achieve technological breakthroughs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

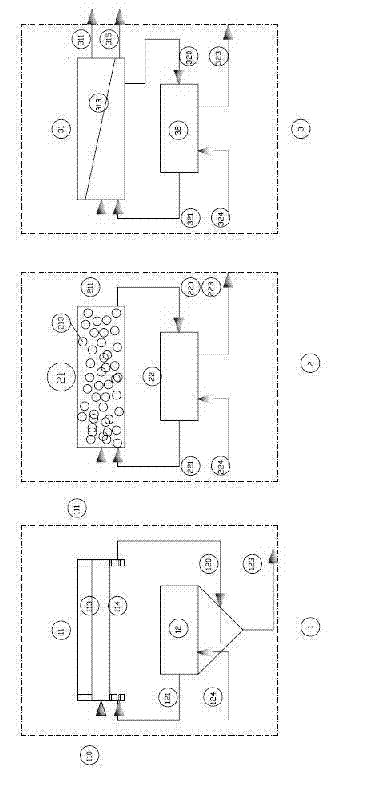

[0040] In conjunction with the accompanying drawings, the specific implementation steps and embodiments of the processing method of the present invention are:

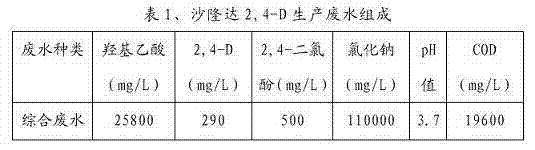

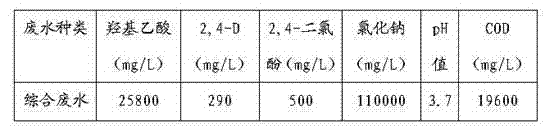

[0041] Wastewater composition: Wastewater is taken from the production wastewater of Sanonda Company in Jingzhou, Hubei, and the specific water quality is as follows.

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a process for processing 2,4-D (2,4-dichlorophenoxyacetic acid) pesticide wastewater, comprising the following steps: extracting the wastewater by using an oil-phase extractant to remove a part of organic matters, adding water phase into an adsorbing system to further remove organic matters, removing salt by using a nanofiltration membrane and optionally cleaning the nanofiltration membrane. The organic matters and the salt in the wastewater can be extracted, concentrated, separated and recycled, and a 2,4-D pesticide wastewater quasi-zero emitting processing cleaner producing process system is formed integrally.

Description

technical field [0001] The invention belongs to the technical field of water treatment, and in particular relates to a method and equipment for treating 2,4-dichlorophenoxyacetic acid (2,4-D) pesticide production wastewater, and belongs to the field of pesticide production wastewater treatment. Background technique [0002] 2,4-dichlorophenoxyacetic acid (2,4-D) and various derivatives produced from 2,4-dichlorophenol are phenoxycarboxylic acid herbicides, which play an important role in increasing the yield of crops It plays an important role and has a wide range of applications. Wastewater containing toxic pollutants such as 2,4-D and 2,4-dichlorophenol is produced in the production process. At present, there are almost no successful examples of methods that can completely treat this type of waste water. The pollution and treatment of this type of waste water have become constraints The bottleneck problem of industry development. Existing treatment technologies for 2,4-D...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F9/02C02F1/26C02F1/28C02F1/44C02F103/36

CPCY02A20/131

Inventor 郭春禹杨慧敏吉春红海龙洋赵雪娜李江王晓琴

Owner 蓝星工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com