Organosilicon-epoxy resin composition and preparation method thereof

A technology of epoxy resin and silicone, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of poor modification effect and low modification efficiency, improve high temperature resistance, increase Compatibility, effect of improving modification efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

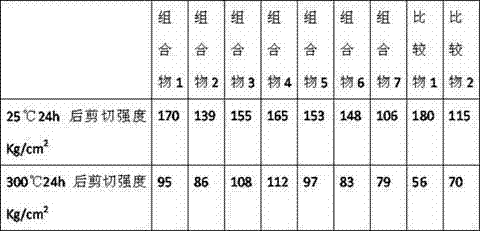

Examples

Embodiment 1

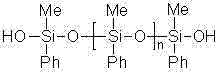

[0022] Weigh 100 parts by weight of epoxy resin (A) bisphenol A epoxy resin E-44, and 20 parts by weight of hydroxyl-terminated polymethylphenylsiloxane (B) (the mass fraction of hydroxyl group is 7.98%) , The weight part of epoxy resin curing agent (C) phthalic anhydride is 180, the weight part of silicone curing agent (D) aminopropyltrimethoxysilane is 0.8, the weight part of silicone curing catalyst (E) dibutyl The weight part of tin dilaurate is 0.5.

[0023] After mixing the epoxy resin and the hydroxyl-terminated polymethylphenylsiloxane uniformly, adding an epoxy resin curing agent, a silicone curing agent and a silicone curing catalyst, and mixing uniformly to prepare Composition 1.

Embodiment 2

[0025] Weigh 100 parts by weight of epoxy resin (A) bisphenol A epoxy resin E-51, and 30 parts by weight of hydroxyl-terminated polymethylphenylsiloxane (B) (hydroxyl mass fraction is 6.45%) , The epoxy resin curing agent (C) has 60 parts by weight of maleic anhydride, the silicone curing agent (D) has 3 parts by weight of aminopropyltriethoxysilane, and the silicone curing catalyst (E) has stannous octoate The weight part is 1.

[0026] The preparation method is the same as in Example 1, and a composition 2 is prepared.

Embodiment 3

[0028] Weigh 100 parts by weight of epoxy resin (A) bisphenol A epoxy resin E-51, and 30 parts by weight of hydroxyl-terminated polymethylphenylsiloxane (B) (hydroxyl mass fraction is 6.45%) , Epoxy resin curing agent (C) The weight part of hexahydrophthalic anhydride is 30, the weight part of maleic anhydride is 60, the weight part of tetrahydrophthalic anhydride is 40, the silicone curing agent (D ) The weight part of aminopropyltriethoxysilane is 3, and the weight part of the organosilicon curing catalyst (E) stannous octoate is 1.

[0029] The preparation method is the same as in Example 1, and a composition 3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com