Grafted copolymer containing reactive groups and application of grafted copolymer

A reactive group, graft copolymer technology, applied in the synthesis and application of graft copolymers, can solve problems such as incompatibility, limited application scope, etc., to improve molecular weight, improve compatibility, The effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

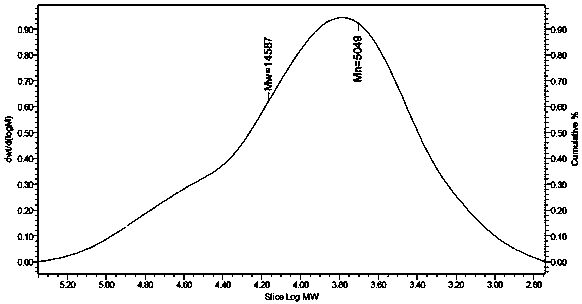

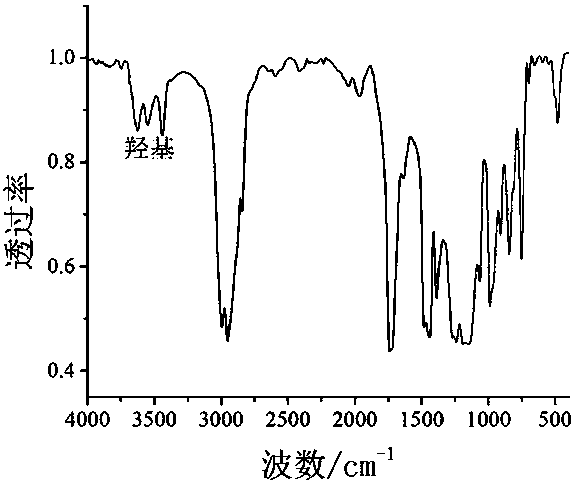

[0055] Under the protection of nitrogen, mix and stir 60g methyl methacrylate, 50g ethyl acrylate, 1.5g chain transfer agent mercaptopropanol, 3.5g initiator azobisisobutyronitrile and 200g solvent toluene, and move to a stirring In a four-necked flask with a paddle, a condenser and a thermometer, heat to 65°C, and react for 6 hours to obtain a toluene solution containing polymer D; lower the reaction system to room temperature, add 0.01g of polymerization inhibitor hydroquinone, 0.04g Catalyst N,N-dimethylbenzylamine and 2.1g of monomer E methacryloyl chloride containing carbon-carbon double bonds (the molar ratio of polymer D to monomer E is 1:1.2), after stirring at room temperature for 8 hours, the product After rotary evaporation and drying, a high molecular polymer C containing carbon-carbon double bonds is obtained. Pass GPC test, such as figure 1 As shown, it can be seen that the number average molecular weight of the obtained high molecular weight polymer C is about ...

Embodiment 2

[0058] Under the protection of nitrogen, mix and stir 80g methyl methacrylate, 20g butyl acrylate, 1.5g chain transfer agent mercaptopropanol, 3.2g initiator azobisisobutyronitrile and 200g solvent toluene, and move to a stirring In a four-necked flask with a paddle, a condenser and a thermometer, heat to 65°C and react for 6 hours to obtain a toluene solution containing polymer D; lower the reaction system to room temperature, add 0.01g of polymerization inhibitor hydroquinone, 0.02g Catalyst triethylamine and 2.1g of monomer E methacryloyl chloride containing carbon-carbon double bonds (the molar ratio of polymer D to monomer E is 1:1.2), stirred and reacted at room temperature for 6 hours, and the product was rotary evaporated and dried to obtain The high molecular weight polymer C containing carbon-carbon double bond can be known by GPC test that the number average molecular weight of the obtained high molecular weight polymer C is about 4200.

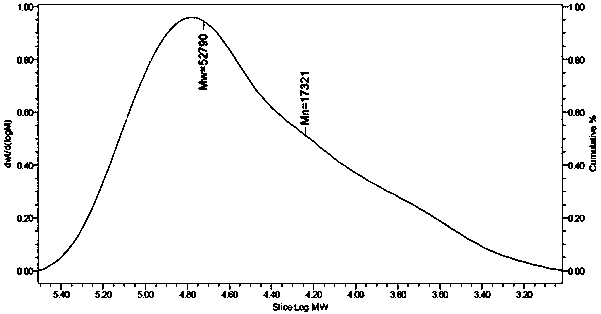

[0059] Under the protection...

Embodiment 3

[0061] Under the protection of nitrogen, mix and stir 80g methyl methacrylate, 20g ethyl acrylate, 3g chain transfer agent mercaptopropanol, 4.5g initiator azobisisobutyronitrile and 300g solvent toluene, and then move to the , a condenser and a thermometer in a four-neck flask, heated to 65°C, and after 6 hours of reaction, a toluene solution containing polymer D was obtained; the reaction system was lowered to room temperature, and 0.01g of inhibitor hydroquinone and catalyst triethyl Amine and 4.2g of monomer E methacrylic acid chloride containing carbon-carbon double bonds (the molar ratio of polymer D to monomer E is 1:1.2), stirred at room temperature for 6 hours, and the product was dried by rotary evaporation to obtain carbon-containing carbon As for the polymer C with double bonds, it can be seen that the number average molecular weight of the obtained polymer C is about 682 through GPC testing.

[0062] Under nitrogen protection, 80g methyl methacrylate, 30g butyl ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com