White thermoplastic polyether ester elastomer composition with good heat stability

A thermoplastic polyether ester and elastomer technology, which is applied in the white thermoplastic polyether ester elastomer composition and its preparation field, can solve the problems of polyether ester elastomer discoloration, application restrictions, color stains, etc., and achieve improved thermal stability , the effect of good dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] The present invention will be further elaborated below in conjunction with specific embodiments. However, these examples are for illustrative purposes only, and are not intended to limit the protection scope of the present invention.

[0057] In the TSSJ-25 twin-screw extruder of Sichuan Chenguang Plastic Machinery Research Institute, the polyether ester elastomer copolymer and various stabilizers were blended and granulated in proportion, and the CJ80E injection molding machine of Guangdong Zhende Plastic Machinery Factory was in accordance with ISO37. Tensile splines are produced as standard, and the surface is visually inspected after aging in an aging oven. If the surface is cracked, the tensile performance test is not performed. If the surface is intact, the tensile performance test is performed on the CMT4202 tensile machine of Shenzhen Xinsansi Test Equipment Factory.

[0058] Observe whether the appearance of the product is deformed and cracked after 180°C / 3 hou...

example 1

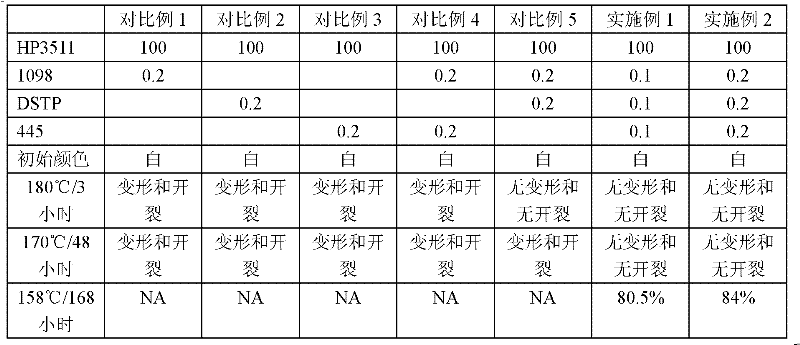

[0069] By changing the combination of stabilizers, its influence on the heat resistance of HP3511 was investigated.

[0070] Table I

[0071]

[0072] NA: surface cracked, not tested

[0073] It can be seen from Table 1 that when the combination of Irganox 1098 / DSTP / Naugard445 stabilizer is used, the heat-resistant and stable effect on the product is obvious.

[0074] Experiment 2

[0075] By changing the combination of stabilizers, the impact on the heat resistance of the product HP4701 was investigated.

[0076] Table II

[0077]

[0078] NA: surface cracked, not tested

[0079] It can be seen from Table 2 that when a single stabilizer is used, the thermal stability effect is poor, and the product is deformed or cracked, which cannot meet the requirements. When phenolic and thiosulfate ester stabilizers are combined, it has a good effect, the product has no deformation and cracking phenomenon, and the tensile strength retention rate is 65.3%, but it still cannot r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com