Preparation method for lanthanum-doped barium ferrite-poly-o-methylaniline composite wave-absorbing material

A composite wave absorbing material, barium ferrite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high density, high relative magnetic permeability, difficult to prepare wave absorbing materials, etc., and achieve wave absorbing performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

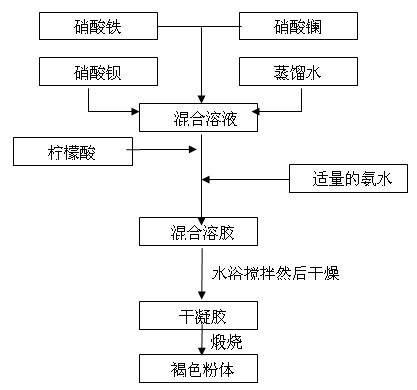

[0019] (1) Accurately weigh 1.96g Ba(NO 3 ) 2 , 0.13g La(NO 3 ) 3 9H 2 O, 36.24g Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water to prepare a mixed solution. Add 20.49g citric acid to the mixed solution. After the dissolution was complete, add an appropriate amount of ammonia water to adjust the pH value to be weakly acidic, then add 2g polyethylene glycol, and age at room temperature for 12 hours. Form a sol, after vacuum drying at 90°C, ignite in the air to form a loose powder bundle, grind and mix, keep at 800°C for 1 hour, heat up to 980°C for 2 hours, and then get lanthanum-doped barium ferrite (x=0.04), preparation process as attached figure 1 shown.

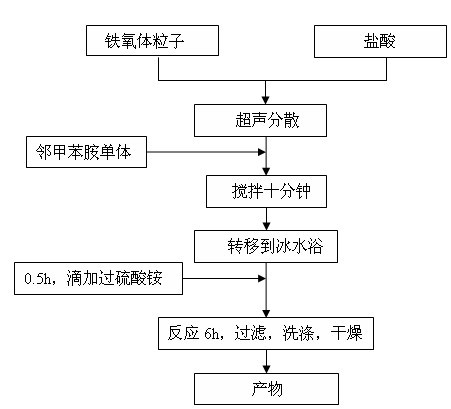

[0020] (2) Add 0.20g of lanthanum-doped barium ferrite (x=0.04) and 1mL of o-toluidine monomer into 100mL of 1.5mol / L hydrochloric acid, ultrasonically disperse them evenly, and place them in an ice-water bath. 4 ) 2 S 2 o 8 The hydrochloric acid solution was added dropwise (about 0.5h) into the above syste...

Embodiment 2

[0022] (1) Accurately weigh 1.96g Ba(NO 3 ) 2 , 0.26g La(NO 3 ) 3 9H 2 O, 36.12g Fe(NO 3 ) 3 9H 2 O, the preparation method is the same as Example 1 (1), that is, lanthanum-doped barium ferrite (x=0.08) is obtained.

[0023] (2) Take 0.20g of lanthanum-doped barium ferrite (x=0.08), and the preparation method is the same as Example 2 (1), that is, the composite wave-absorbing material of lanthanum-doped barium ferrite-poly-o-toluidine (x=0.08 ), the highest absorption peak of the prepared composite absorbing material can reach -38dB within 1-20GHz.

Embodiment 3

[0025] (1) Accurately weigh 1.96g Ba(NO 3 ) 2 , 0.39g La(NO 3 ) 3 9H 2 O, 36.00g Fe(NO 3 ) 3 9H 2 O, the preparation method is the same as Example 1 (1), that is, lanthanum-doped barium ferrite (x=0.12) is obtained.

[0026] (2) Take 0.20g of lanthanum-doped barium ferrite (x=0.12), and the preparation method is the same as Example 2 (1), that is, the composite wave-absorbing material of lanthanum-doped barium ferrite-poly-o-toluidine (x=0.12 ), the highest absorption peak of the prepared composite absorbing material can reach -40dB within 1-20GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com