Formula and preparation process of food can inner wall coating

A technology for cans and coatings, which is applied in the formulation and production process of food can inner wall coatings. It can solve the problems of easy wear and tear of synthetic wax coatings, lunch meat sticking to cans, and inconvenience to consumers, and achieve good food corrosion resistance and growth. Effect of storage time and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

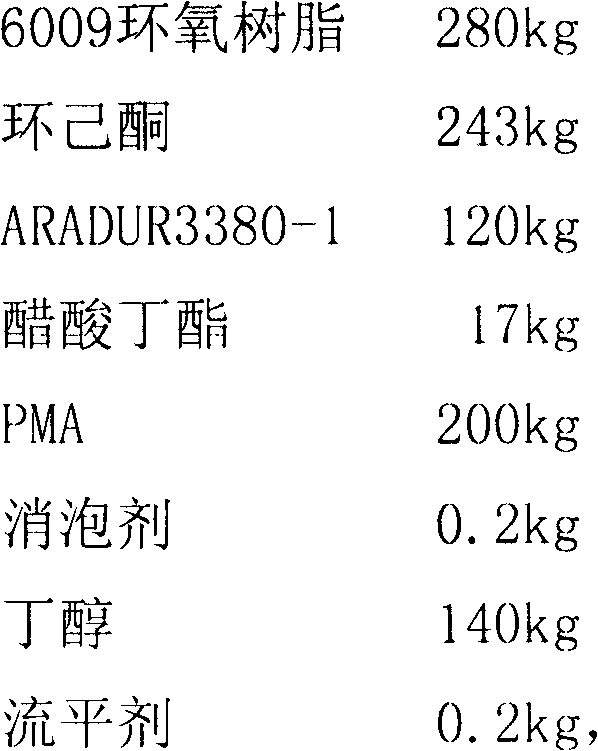

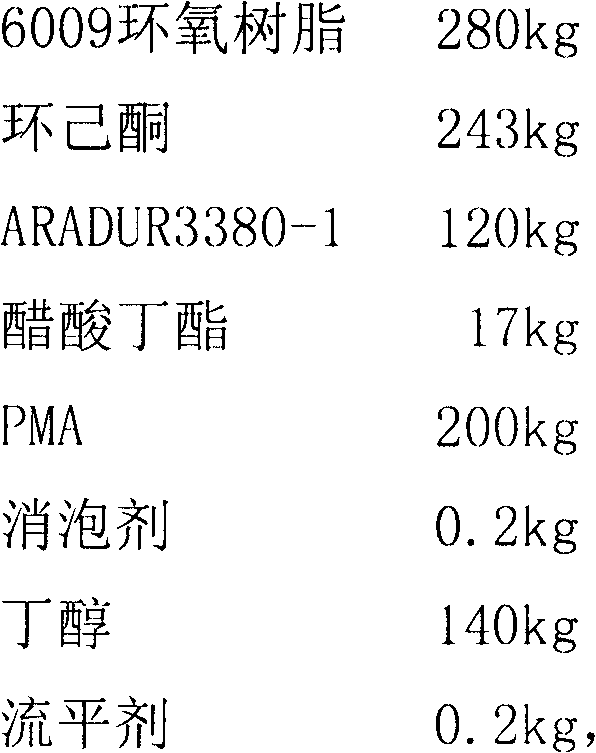

[0027] a. Prepare material A, weigh 280kg of 6009 epoxy resin, 243kg of cyclohexanone, ARADUR3380-1120kg, 17kg of butyl acetate, 200kg of PMA, 0.2kg of defoamer, 140kg of butanol, 0.2kg of leveling agent, 6009 epoxy resin , cyclohexanone, butyl acetate, PMA, and butanol are mixed and put into the reactor for stirring, heated to 120°C for reflux dehydration for 60 minutes, add ARADUR3380-1 and continue reflux dehydration for 30 minutes, cool to 60°C and add leveling agent and defoamer, after 40°C, discharge, filter and pack into barrels for later use;

[0028] b. Prepare material B, weigh 100kg of material A and 5kg of zinc oxide, put material A and zinc oxide into the pulling tank for dispersion, then sand grind the slurry, and stop the machine fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com