Silicon wafer cleaning liquid

A silicon wafer cleaning and concentration technology, applied in the direction of inorganic non-surface active cleaning composition, organic non-surface active cleaning composition, etc., can solve problems such as pollution and difficult handling, achieve thorough cleaning, strong cleaning effect, and improve subsequent use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

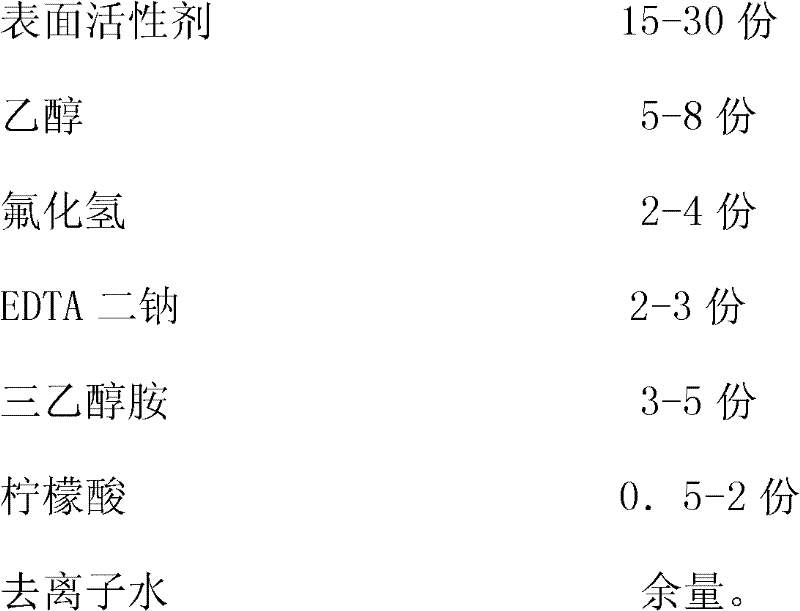

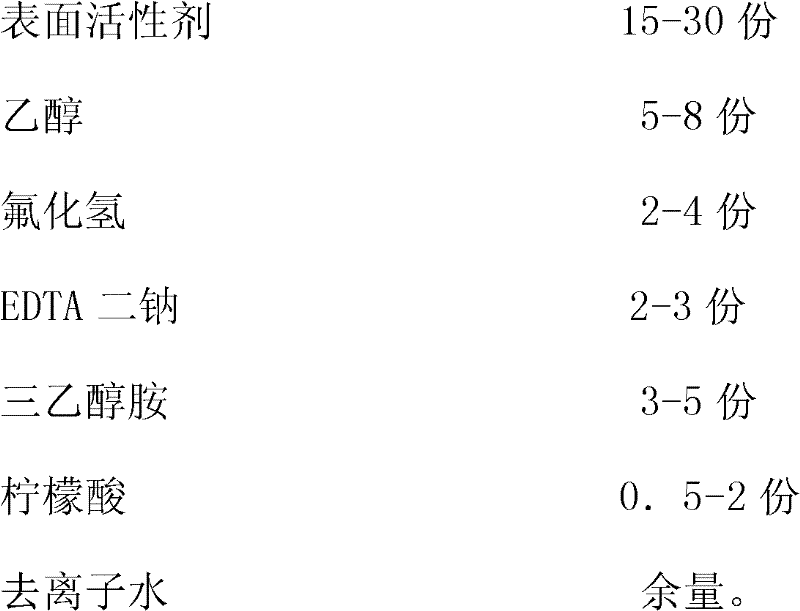

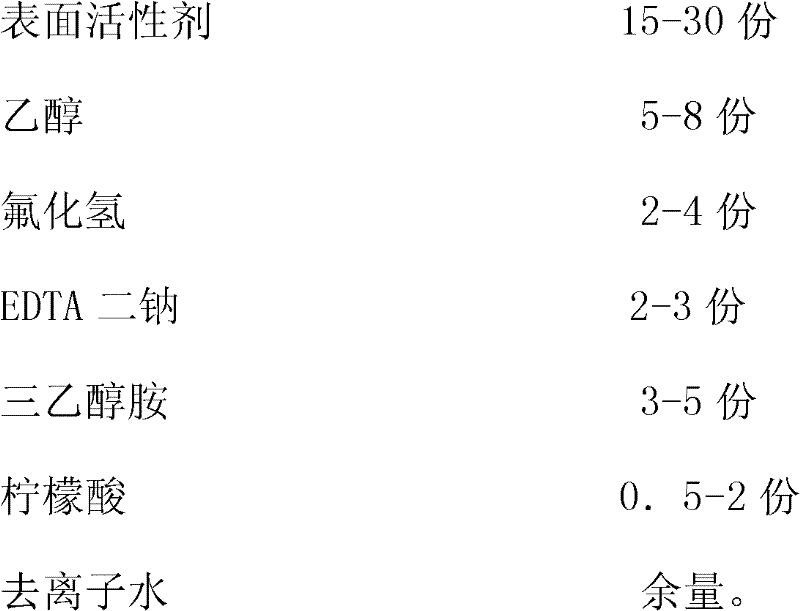

[0018] Stir and mix 15 parts of surfactant, 5 parts of ethanol, 2 parts of hydrogen fluoride, 2 parts of disodium EDTA, 3 parts of triethanolamine, 0.5 parts of citric acid, and the rest of deionized water to form a cleaning solution. The concentration of ethanol is 90%, and the concentration of citric acid is 10%.

[0019] Performance indicators: 1000 pieces of silicon wafers are cleaned, and the cleaning degree reaches 98.9%.

Embodiment 2

[0021] Stir and mix 20 parts of surfactant, 6 parts of ethanol, 3 parts of hydrogen fluoride, 2 parts of disodium EDTA, 4 parts of triethanolamine, 1 part of citric acid, and the rest of deionized water to form a cleaning solution. The concentration of ethanol is 98%, and the concentration of citric acid is 10%.

[0022] Performance indicators: 1000 pieces of silicon wafers are cleaned, and the cleaning degree reaches 99.9%.

Embodiment 3

[0024] Stir and mix 30 parts of surfactant, 5 parts of ethanol, 2 parts of hydrogen fluoride, 2 parts of disodium EDTA, 3 parts of triethanolamine, 0.5 parts of citric acid, and the rest of deionized water to form a cleaning solution. The concentration of ethanol was 100%, and the concentration of citric acid was 10%.

[0025] Performance index: Clean 1000 pieces of silicon wafers, and the cleaning degree reaches 99.6%.

[0026] The preparation method of the present invention is simple, has no adverse effect on the environment, and has strong detergency on the surface, can maintain the continuity of cleanliness, has a good cleaning effect on materials such as polycrystalline silicon wafers, and improves cleaning speed and durability; the present invention adopts Ethanol cleans the organic contamination on the surface of the silicon wafer. In addition, the oxide layer is cleaned by hydrogen fluoride, so that the cleaning of the silicon wafer is more thorough, and it has a stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com